Labor-saving bolt clipper

A technology of bolt cutters and handles, applied in the direction of pliers, manufacturing tools, etc., can solve the problems of enlargement, increase the labor intensity of operators, etc., and achieve the effect of increasing the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

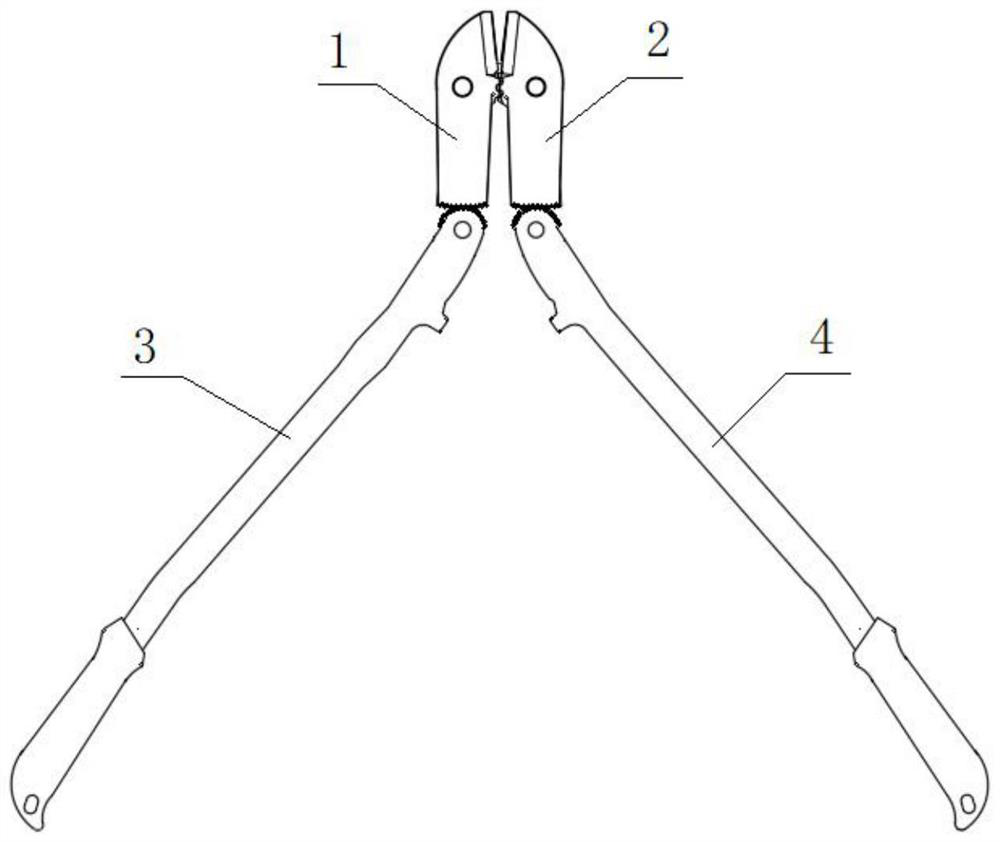

[0018] Such as figure 2 Shown is a schematic diagram of the structure of the present invention without a pressure plate.

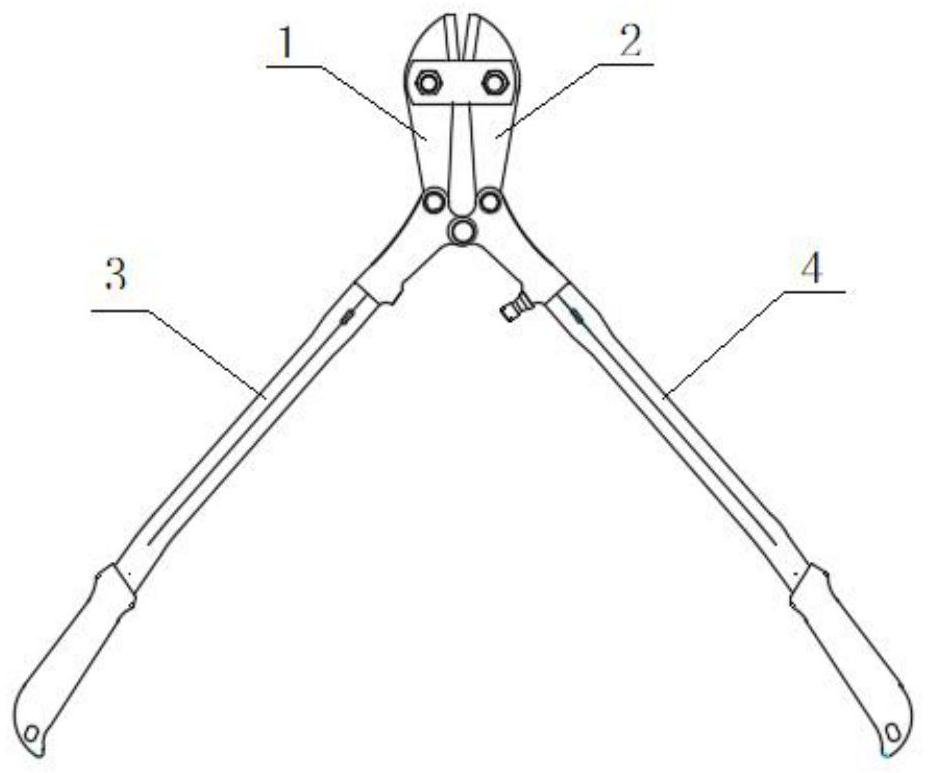

[0019] The cutter head includes a first cutter head 1 and a second cutter head 2, and the handle includes a first handle 3 and a second handle 4. The first handle 3 and the second handle 4 are fixedly connected by a joint arm and a handle. With rubber non-slip cover.

[0020] The lower end of the first cutter head 1 and the second cutter head 2 is in the shape of a cylindrical gear, the lower end of the first handle 3 and the second handle 4 is in the shape of a cylindrical gear, and the cylindrical gear at the lower end of the first cutter head 1 is in the shape of a cylindrical gear at the upper end of the first handle 3. The cylindrical gear is meshed and connected, and the cylindrical gear at the lower end of the second cutter head 2 is meshed with the cylindrical gear at the upper end of the second handle 4 .

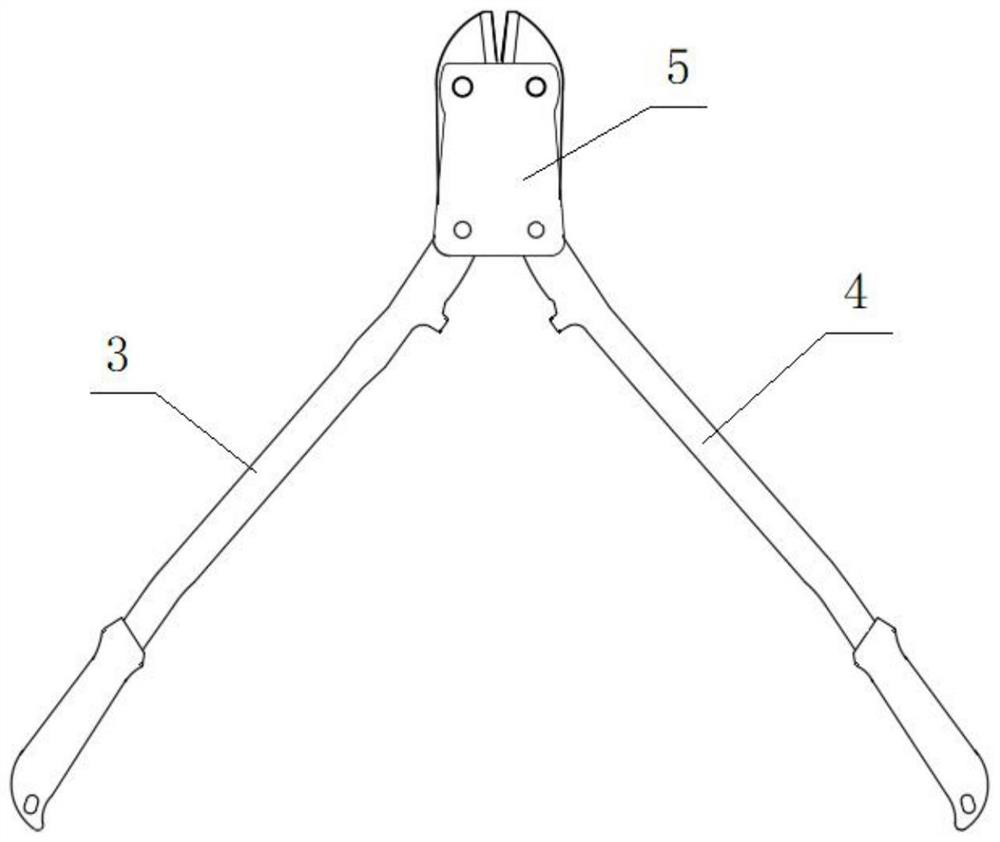

[0021] Such as image 3 Shown is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com