Pearl wool filling machine

A cotton filling machine and pearl technology, applied in the field of cotton fiber equipment, can solve the problems of low degree of automation, insufficient opening, poor ball forming effect, etc., and achieve good opening effect, sufficient opening, and increased range of motion big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

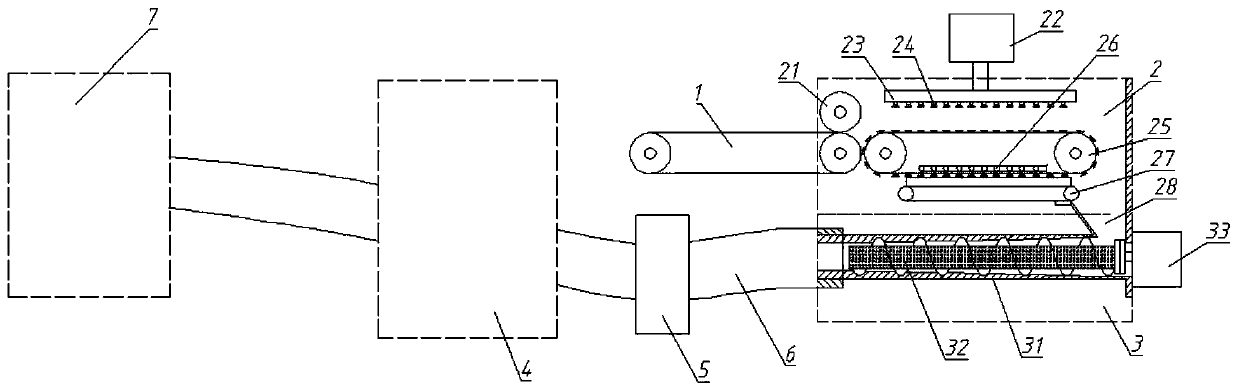

[0035] Such as Figure 1-17 A pearl cotton filling machine shown includes a tearing mechanism 2 connected by a pipeline 6 , an opening mechanism 3 , a cotton ball machine 4 and a cotton filling mechanism 7 .

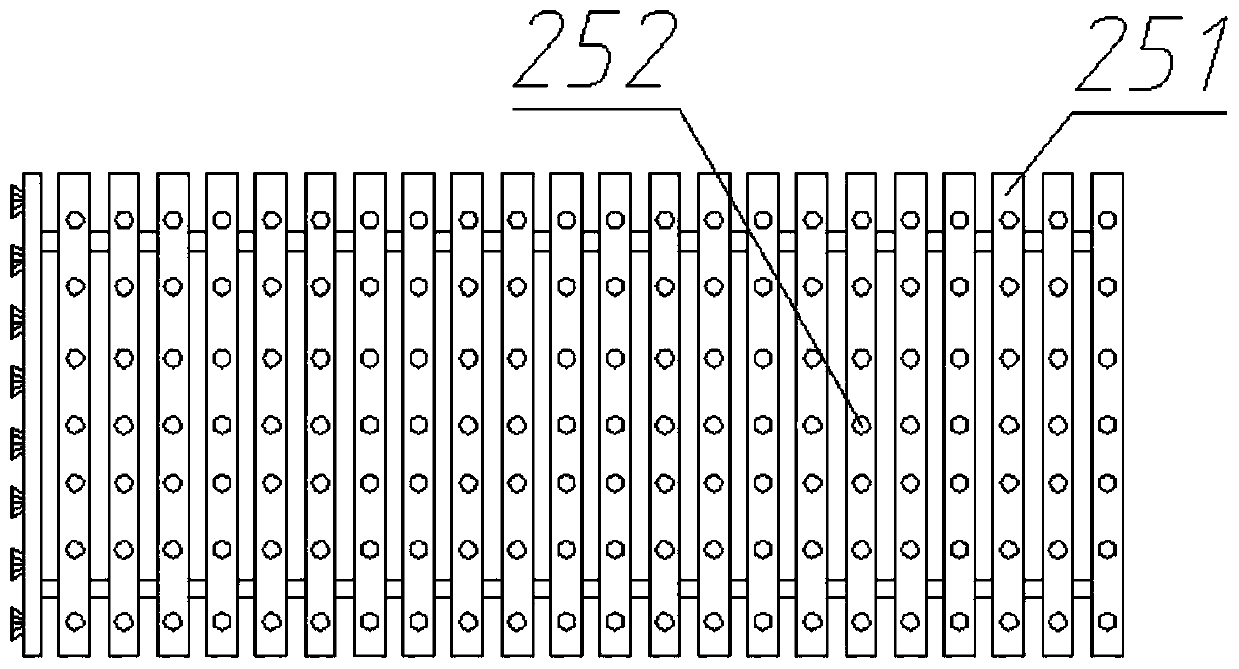

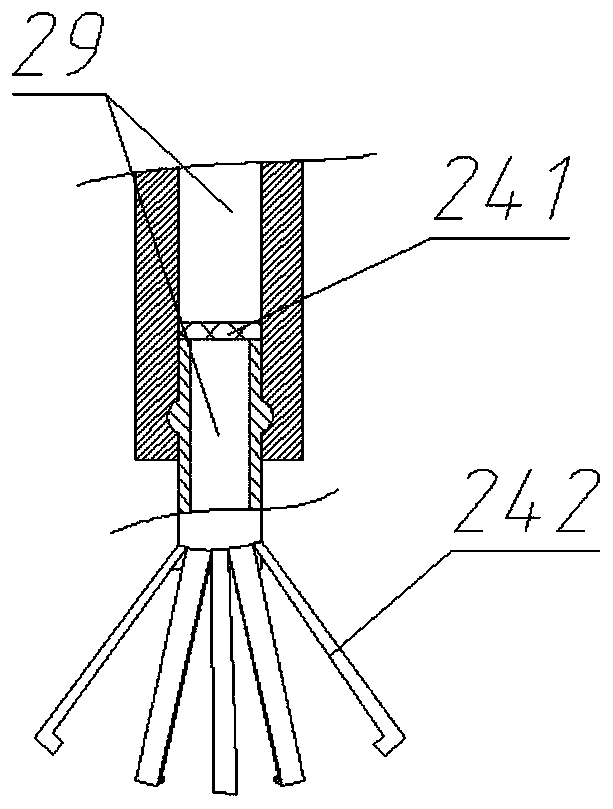

[0036]After being transported by the feeding belt 1, the raw pearl cotton enters the ripping mechanism 2 for preliminary ripping. The feeding end of the ripping mechanism 2 is provided with a pressing roller 21 that matches the feeding belt 1 to squeeze the raw pearl cotton, so that the raw pearl cotton Smoothly enter the first conveyor belt 25 and tear it loose. The transmission surface of the first conveyor belt 25 is composed of several parallel strip plates 251. The lower end surface of the strip plate 251 is fixed on the transmission chain so that the strip plate 251 follows the transmission chain. Simultaneous movement, several circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com