Intelligent automatic conveying vehicle for aviation epidemic prevention

An automatic conveying vehicle and conveying vehicle technology, which is applied in the fields of cargo transportation and logistics and warehousing, can solve the problems of low degree of automation, overturned luggage trays, and no space constraints, and achieves network intelligent remote control, high degree of intelligence, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

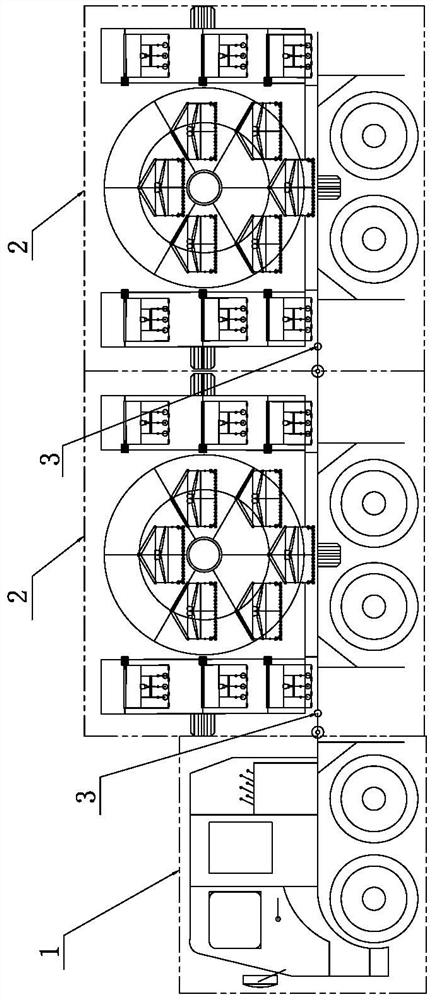

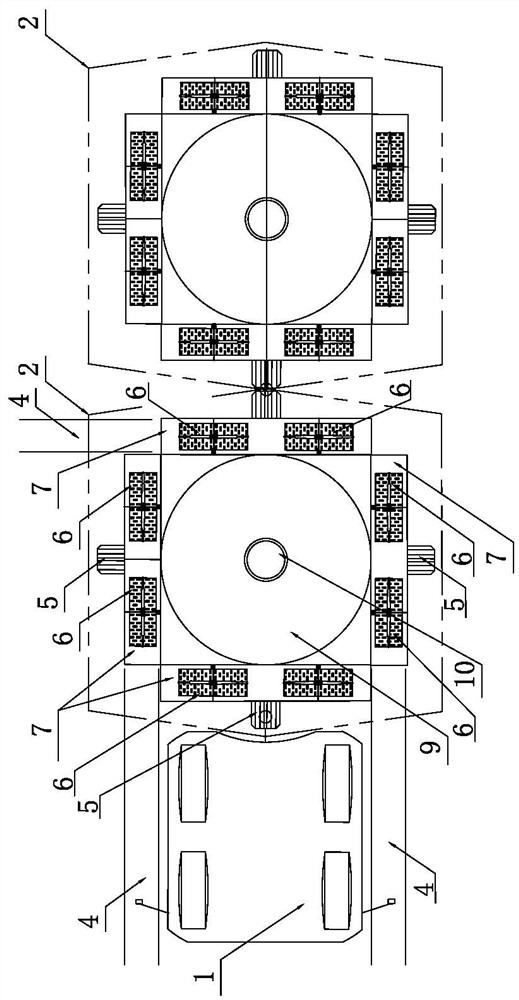

[0026] like figure 1 , figure 2 , image 3 As shown, the intelligent traction control vehicle 1 is connected to control a plurality of automatic loading and unloading conveyor vehicles 2, preferably 2 to 3 automatic loading and unloading conveyor vehicles 2; the intelligent traction control vehicle 1 is equipped with a Beidou navigation and PLC control unit, which can be operated automatically or Manual operation, traction and control of the movement of the automatic loading and unloading conveyor vehicle 2 .

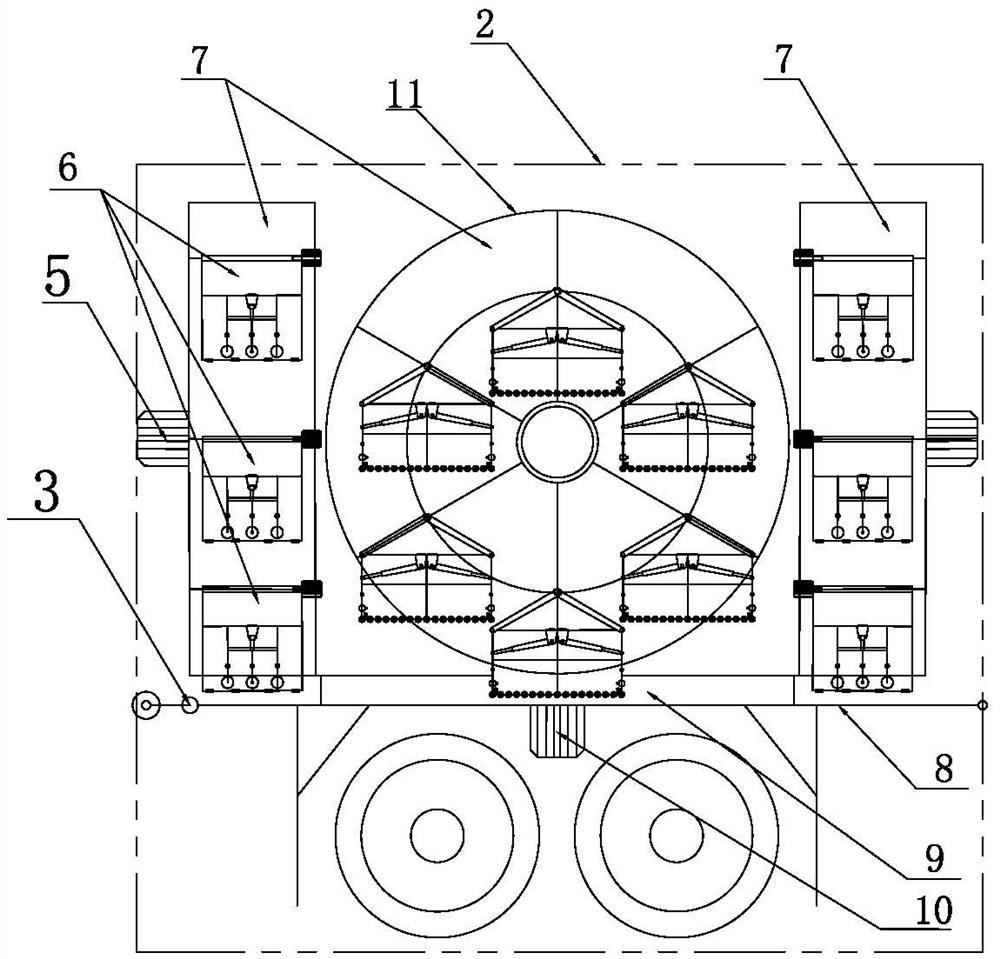

[0027] like image 3 As shown, the automatic loading and unloading conveyor vehicle 2 is composed of a chassis 7 and a turntable 8. A position sensor 3 is arranged below the chassis 7. A turntable 8 is installed horizontally on the chassis 7. The center of the turntable 8 is connected to the servo motor B10. Loading and unloading racks 7, preferably the number of intelligent loading and unloading racks 7 is 4,6,8.

[0028] like Figure 4 , Figure 5 , Image 6 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com