Gangue filling underground system

A technology of gangue and gangue racks, which is applied in the field of gangue filling underground systems, can solve the problems of large impact force in underground gangue backfilling, plugging of feeding wells, etc., and achieve the effects of reducing danger, avoiding dust, and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

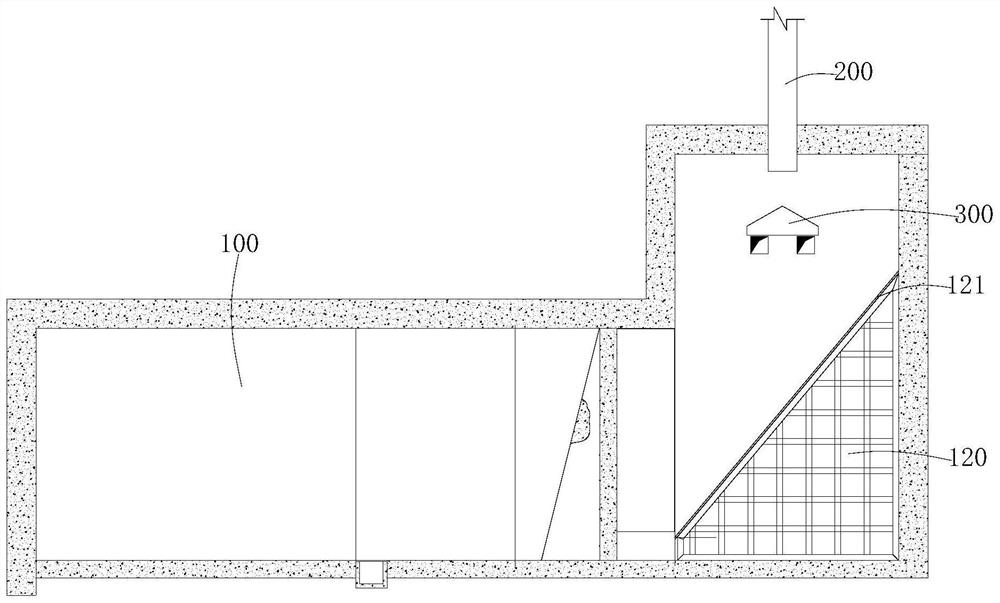

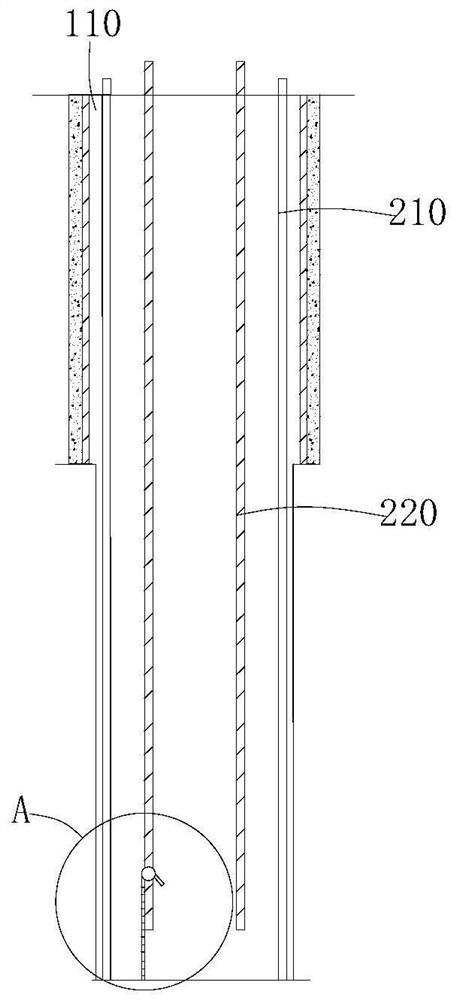

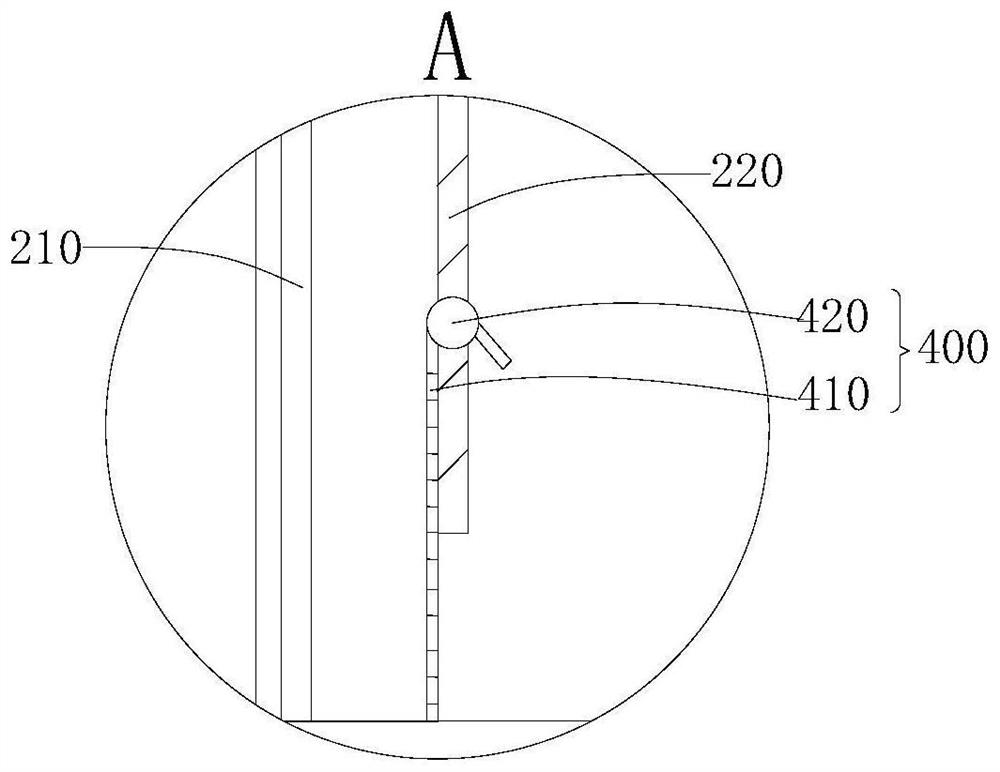

[0042] see figure 1 , the present application provides a technical solution: a gangue filling downhole system, including a loading chamber 100 , a feeding assembly 200 and a buffer assembly 300 .

[0043] Among them, see figure 1 , the feeding assembly 200 and the buffer assembly 300 are arranged in the loading chamber 100, the gangue backfilled on the ground can be transported to the loading chamber 100 through the feeding assembly 200, and the buffer assembly 300 can absorb the shock of the gangue conveyed by the feeding assembly 200 Cushioning, so as to avoid certain damage caused by huge impact force or huge dust.

[0044] see figure 1 and figure 2 , the loading chamber 100 located under the ground, and the receiving hole 110 connected to the loading chamber 100 on the ground, wherein, the loading chamber 100 is provided with a sliding gangue rack 120, specifically, the gangue sliding rack 120 has gradually Inclined slope 121, wherein, the slope 121 is 50°, to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com