Glass fiber reinforced plastic cooling tower

A glass fiber reinforced plastic, cooling tower technology, applied in water shower coolers, lighting and heating equipment, heat exchanger types, etc., can solve problems such as water loss, and achieve the effect of preventing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

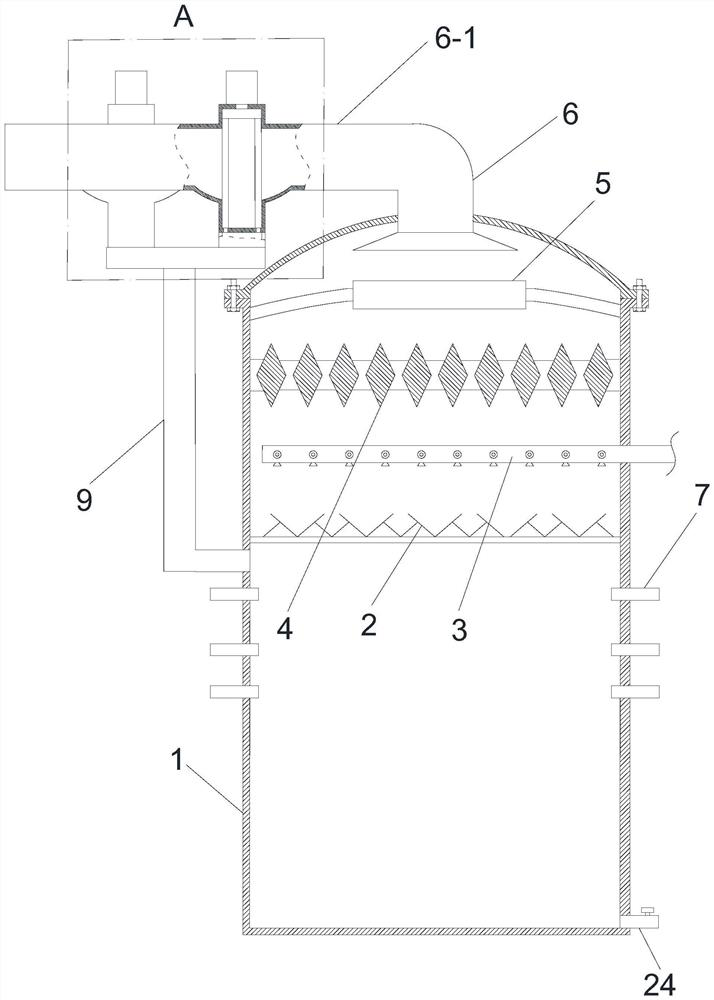

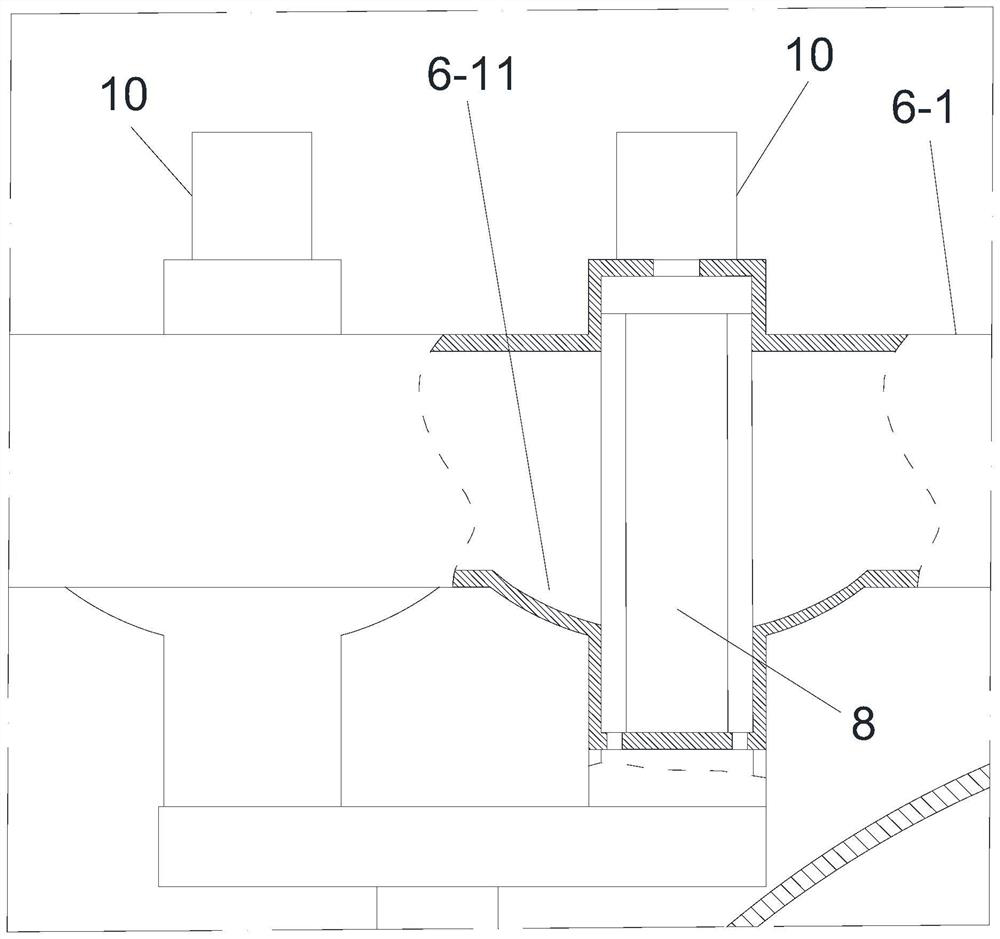

[0023] Embodiment 1, the present invention provides a kind of glass fiber reinforced plastic cooling tower, refer to figure 1 and figure 2 , including a tower body 1, the tower body is sequentially provided with a radiator 2, a spray pipe 3 and a glass fiber reinforced plastic water retaining assembly 4 from bottom to top, wherein the radiator can be an existing structure, such as cooling tower packing, cooling tower heat dissipation components, etc.; the spray pipe and the glass water blocking component can be set in the existing way; the induced draft fan 5 is arranged above the glass fiber reinforced plastic water blocking component, and the induced draft pipe is installed on the tower body corresponding to the position of the induced draft fan 6. The tower body is provided with an air inlet pipe 7, and the air inlet pipe is located below the radiator body. Generally, a filter screen and other structures are also arranged in the air inlet pipe to prevent the entry of exter...

Embodiment 2

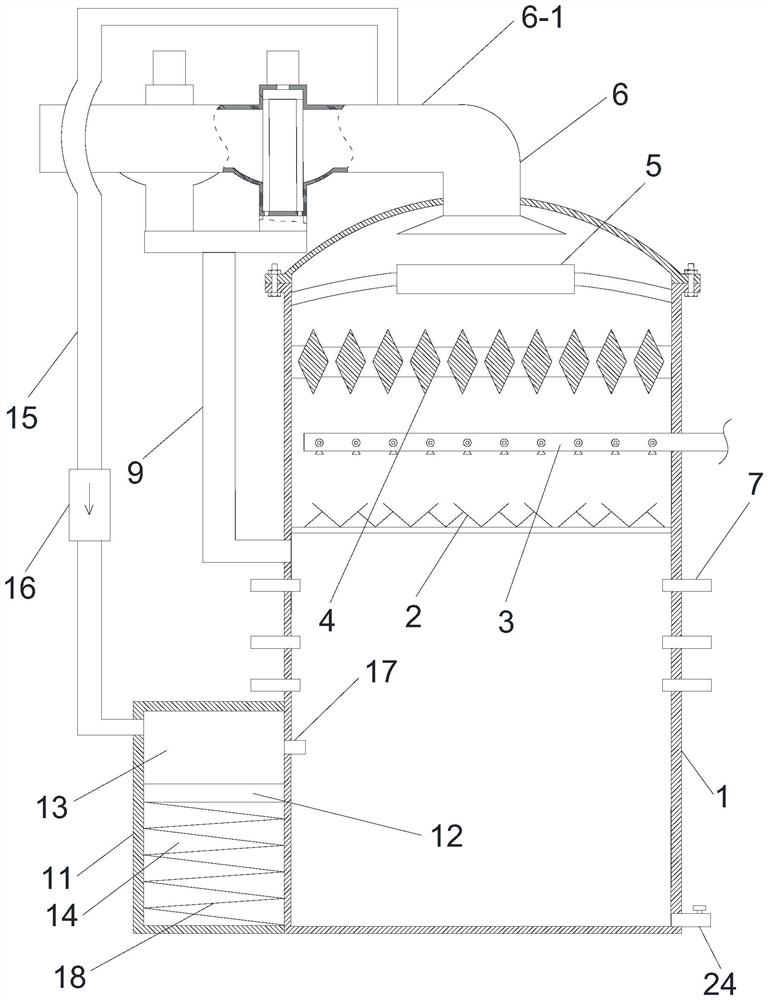

[0027] Example 2, on the basis of Example 1, the applicant also made the following design, see image 3 , the outer side of the tower body is provided with a shielding body 11, a chamber is formed between the shielding body and the tower body, a piston 12 is arranged in the chamber, and the piston divides the chamber into a first chamber chamber 13 and second chamber 14, the first chamber is located above the second chamber, an air duct 15 is arranged between the air duct and the shielding body, and the air duct is One end is connected with the air induction pipe, the connection position is located between the water collecting tank and the tower body, and the other end of the air guide pipe is connected with the shielding body, and the connection position is located at the top of the shielding body, also It is set corresponding to the first chamber; the air duct is provided with a first one-way valve 16, and the first one-way valve can make the medium (gas) in the air duct to ...

Embodiment 3

[0029] Example 3, on the basis of Example 1, the applicant also made the following design, see Figure 4 , the outer side of the tower body is provided with a shielding body 11, a chamber is formed between the shielding body and the tower body, a piston 12 is arranged in the chamber, and the piston divides the chamber into a first chamber chamber 13 and second chamber 14, the first chamber is located above the second chamber, an air duct 15 is arranged between the air duct and the shielding body, and the air duct is One end is connected with the air induction pipe, the connection position is located between the water collecting tank and the tower body, the other end of the air guide pipe is connected with the shielding body, and the connection position is set corresponding to the second chamber; The air duct is provided with a first one-way valve 16, and the first one-way valve can make the medium (gas) in the air duct flow in the direction of the first chamber; A communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com