Infrared and microwave collaborative curing box and potato curing method

A curing box and microwave technology, which is applied in microwave heating, electric/magnetic/electromagnetic heating, electric heating devices, etc., can solve the problems of poor microwave flavor, harm to human health, and prone to scorched gelatinization, etc., so as to ensure the flavor of potatoes , prevent water loss, avoid the effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

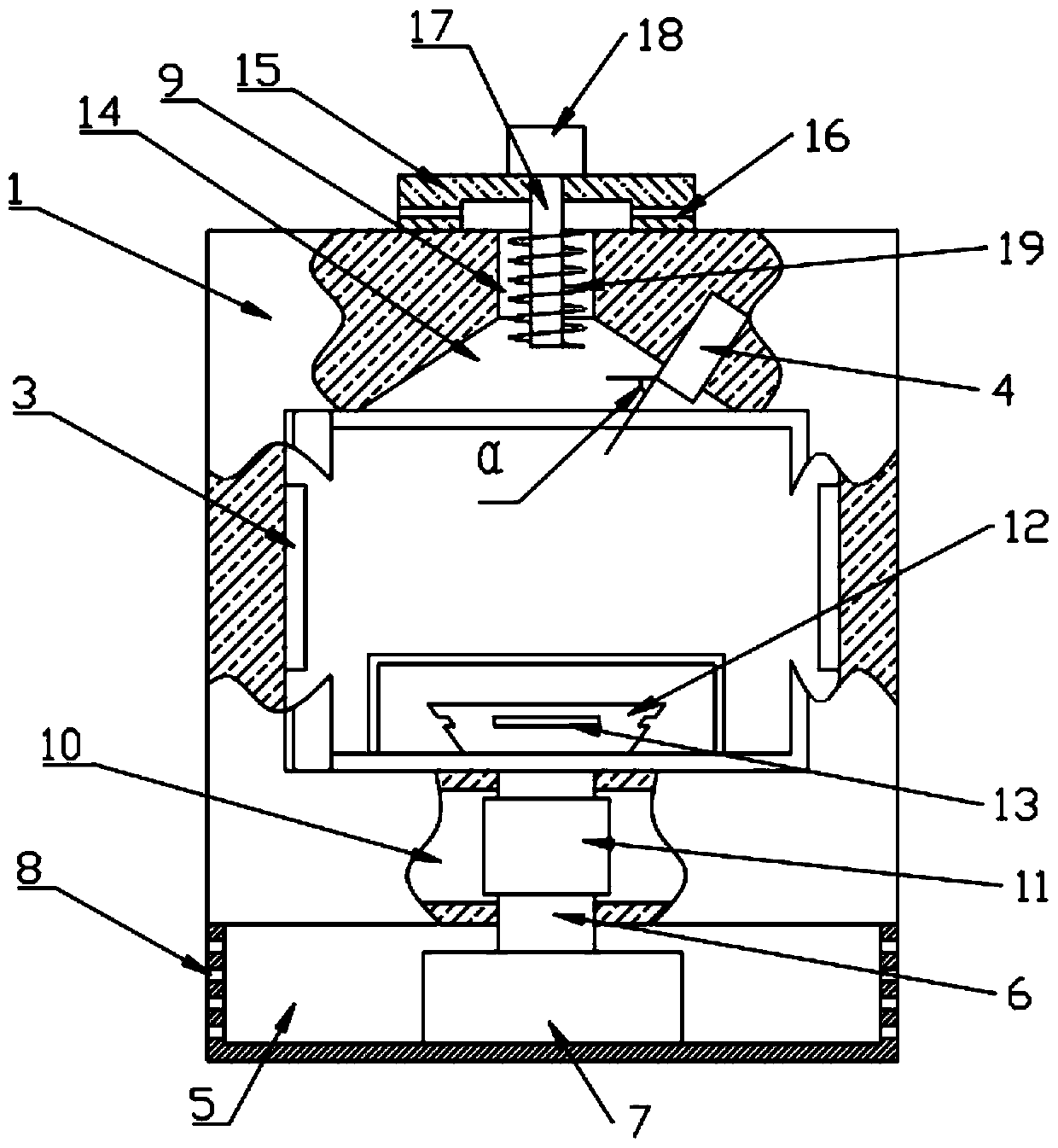

[0038] see Figure 1 to Figure 2 , an infrared and microwave synergistic curing box, comprising a box body 1 provided with a box door 2, an infrared emitter 3 positioned at two opposite side walls is vertically arranged in the box body 1, infrared emitters 3 are arranged on both sides, and the emitted infrared rays After being reflected by the inner wall of the box body 1, it can fill the whole box body 1, which can ensure that the irradiated surface of the heated object is more uniform. The box body 1 is also provided with a microwave transmitter 4 located on the upper wall; The installation box 5 is installed with the blower fan 7 that the air outlet pipe 6 extends upwards and communicates with the box body 1, and the installation box 5 is also provided with some air inlets 8 for the use of the blower fan 7 and can assist the blower fan 7 at the same time It dissipates heat by itself; it also includes an exhaust channel 9 arranged on the upper wall of the box body 1 and comm...

Embodiment 2

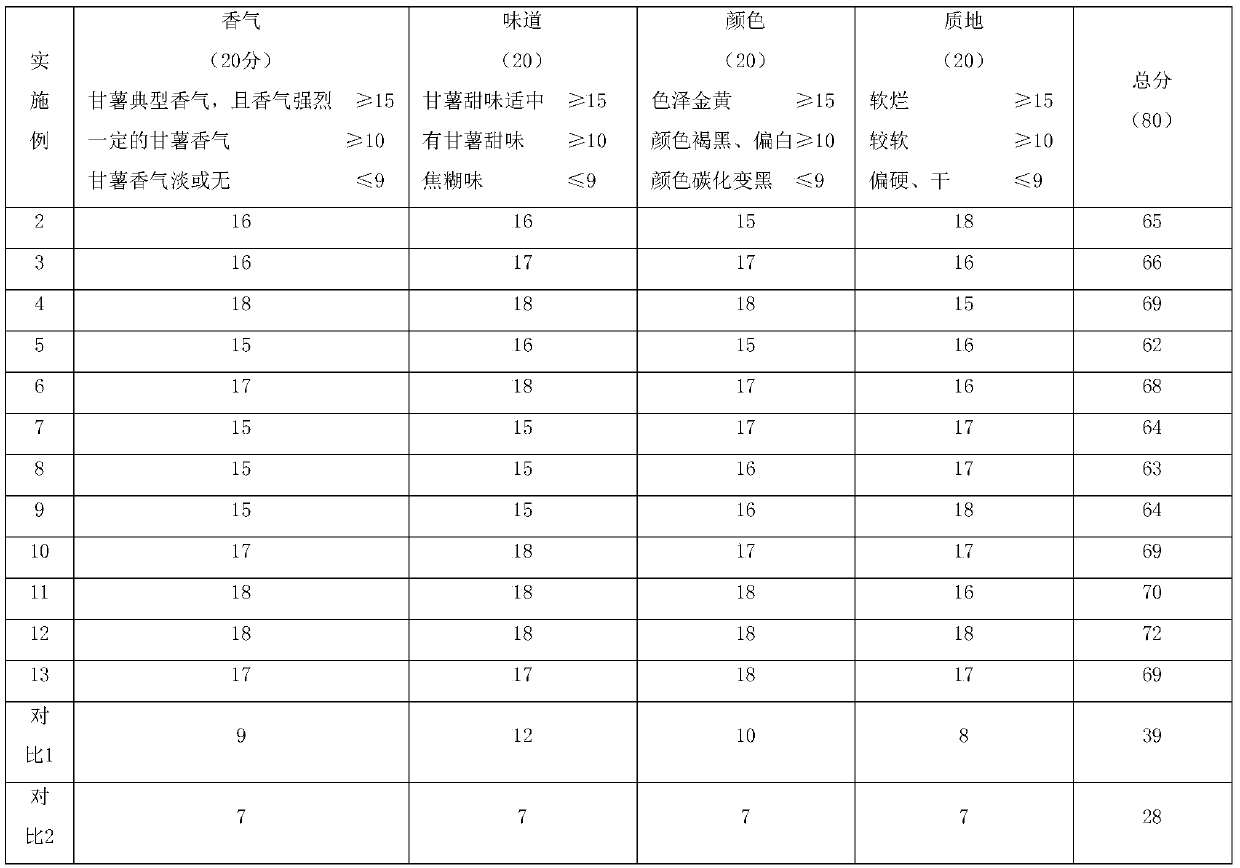

[0050] A potato ripening method, first wash the sweet potatoes, put them on the support frame, move them into the ripening box, close the box door 2, then turn on the fan 7 and the electric heating ring 11, and wait until the temperature in the ripening box rises to 50°C Keep for 5 minutes, then turn on the infrared emitter 3, irradiate with infrared light for 5 minutes, then turn off the infrared emitter 3, then turn on the microwave emitter 4, turn off the microwave emitter 4 after 8 minutes of microwave irradiation, open the box door 2 and take out the sweet potatoes.

Embodiment 3

[0052] A potato ripening method, first wash the sweet potatoes, place them on a support frame, move them into a ripening box, close the box door 2, then turn on the fan 7 and the electric heating ring 11, and wait until the temperature in the ripening box rises to 55°C Keep it for 4 minutes, then turn on the infrared emitter 3, irradiate with infrared light for 8 minutes, then turn off the infrared emitter 3, then turn on the microwave emitter 4, turn off the microwave emitter 4 after 12 minutes of microwave irradiation, open the box door 2 and take out the sweet potatoes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com