Dental implant fatigue test device

A fatigue test and implant technology, applied in measuring devices, scientific instruments, instruments, etc., can solve the problems such as the inability to flexibly adjust the neutrality of the loading device and the bearing parts, the difficulty of the implant fatigue test, and the low fault tolerance rate. Guarantee the effect of neutrality, simplified tooling and good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

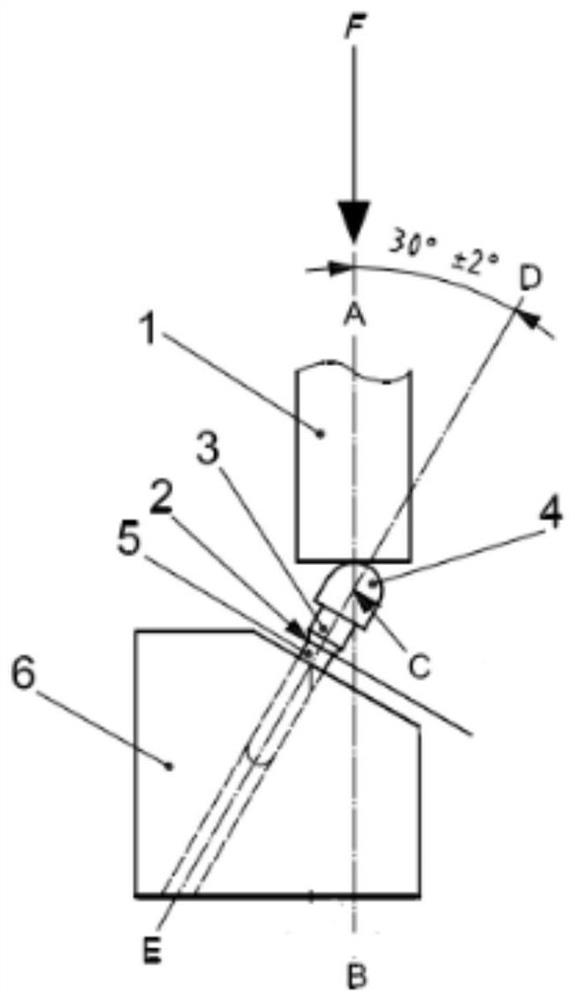

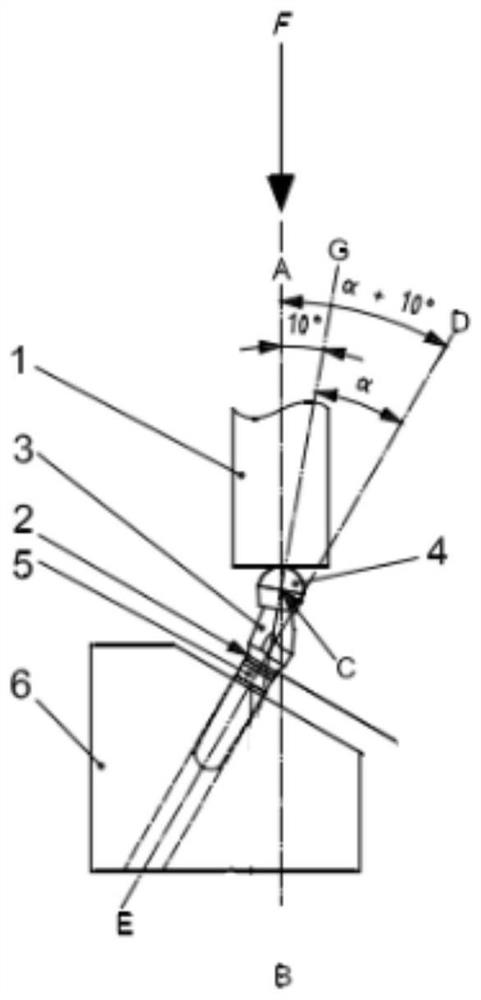

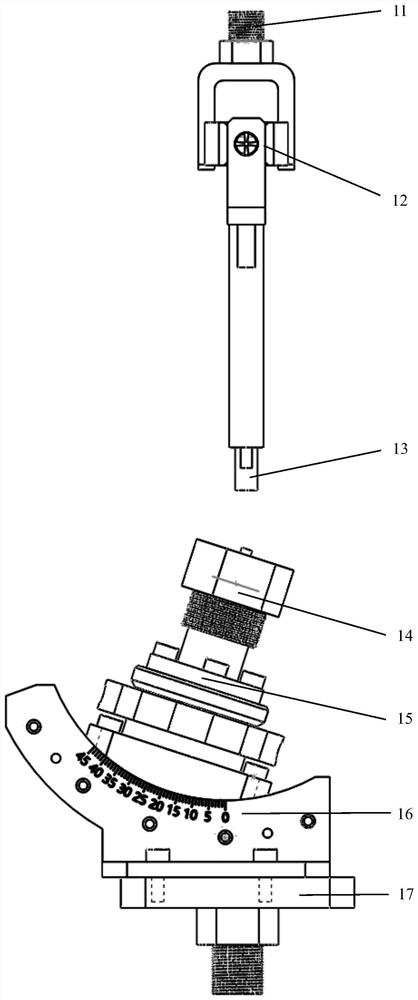

[0028] Such as image 3 The dental implant fatigue test device of the present invention as shown includes a loading device and a fixing device. The loading device includes a cross-staggered universal joint structure 12, and the universal joint structure 12 includes a rectangular body spring frame 115. On the spring frame The middle of each outer wall of 115 has a groove along the vertical direction, and the middle of the bottom wall of each groove is fixedly connected with one end of the torsion spring 113 arranged in the horizontal direction. The left and right wings of an n-shaped upper frame body 112 The lower part of the flange plate is respectively fixedly connected with the other ends of the two torsion springs arranged along the axis line in a straight line, and the upper parts of the left and right flange plates of a U-shaped lower fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com