Module combined type batching control system

A control system and combined technology, applied in general control systems, control/regulation systems, program control, etc., can solve the influence of cable length and quality transmission data accuracy and timeliness, high technology selection cost, and type selection. Long time and other problems, to achieve the effect of improving the comprehensive response speed of the equipment, reducing the acquisition delay time, and good anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

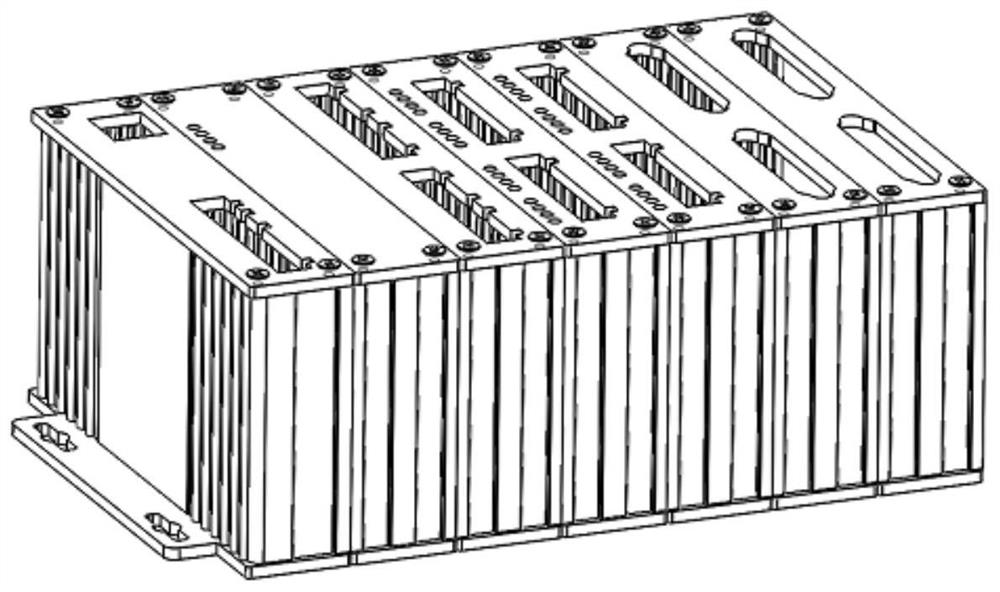

[0024] A modular combined batching control system, including a power communication board, a CPU main control board, an analog input board, a switch input board, a switch output board, a wireless communication board and an aluminum alloy shell, a power communication board, and a CPU main control board , analog input board, digital input board, digital output board, and wireless communication board are integrated in an aluminum alloy casing, and all modules in the aluminum alloy casing adopt a combination of double-row pin insertion.

[0025] The power communication board is a necessary module of the control system. One side of the power communication board has a double-row pin female seat. This structure allows the power communication board and other functional boards to be used in combination through double-row pins and double-row pin female seats. The power communication board includes the power module and communication module required by the system. The power module supplies ...

Embodiment 2

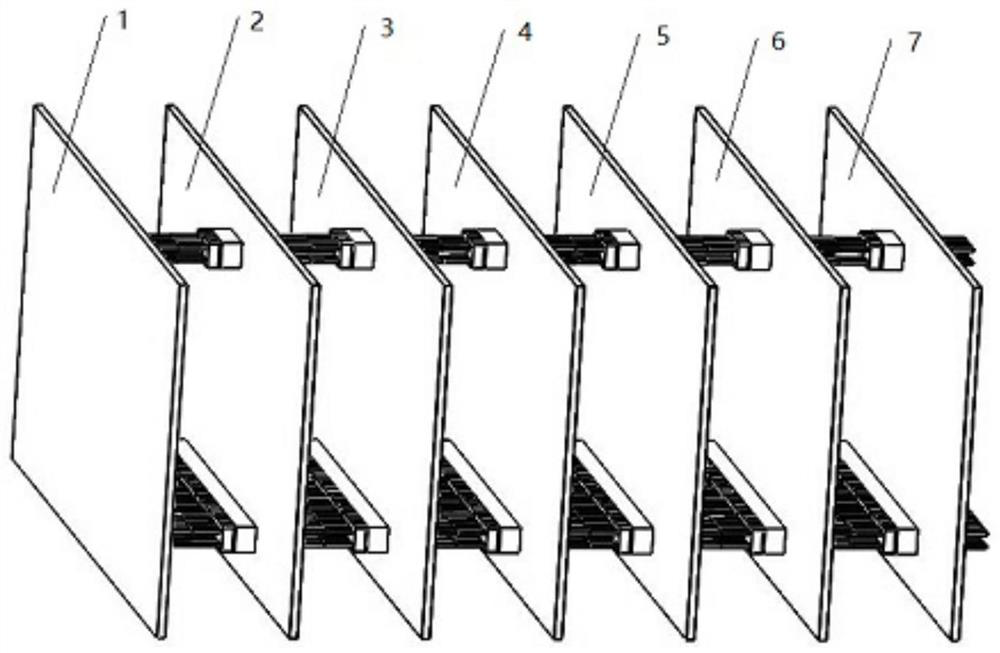

[0033] figure 1 An embodiment of a control system according to the present invention is shown, and the designer provides a set of non-specialized, easy-to-use, unified interface, and reusable control system function boards. In this embodiment, the functional modules are each connected only to two adjacent functional boards.

[0034] figure 1 The No. 1 position is fixed as the power communication board.

[0035] figure 1 The No. 2 position is fixed as the CPU main control board.

[0036] figure 1 In the No. 3 position, you can choose any one of the analog input board, digital input board, and digital output board for combination.

[0037] figure 1 In the No. 4 position, you can choose any one of the analog input board, digital input board, and digital output board for combination.

[0038] figure 1 In the No. 5 position, you can choose any one of the analog input board, digital input board, and digital output board for combination.

[0039] figure 1 In the No. 6 posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com