Integrated ejector, fuel cell hydrogen supply system and control method of fuel cell hydrogen supply system

A technology of ejector and controller, which is applied in the field of fuel cells, can solve the problems of complicated ejector structure design, inability to meet the rapid response of sudden rise and fall, and difficult coverage of ordinary ejectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

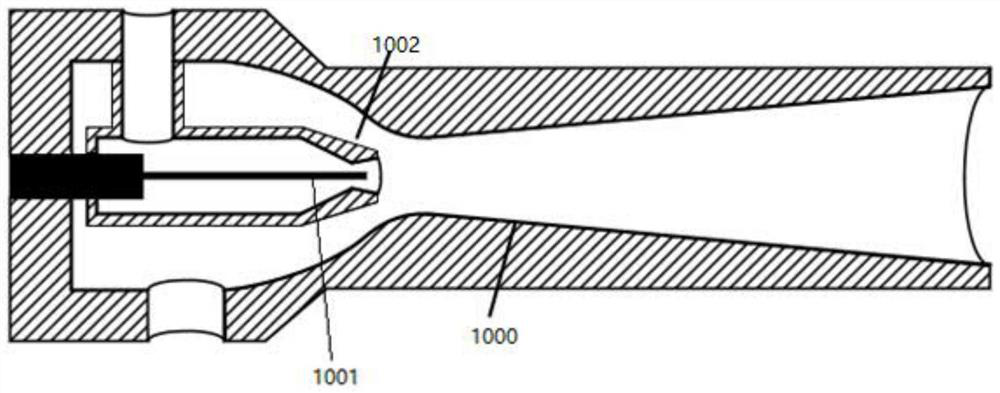

[0046] Discovered by the inventor, the ejector 1000 of prior art, please refer to figure 1 , the existing nozzle 1002 is pierced with a variable adjusting needle 1001, the section of the nozzle is adjusted through the adjusting needle 1001 in the existing nozzle 1002, so that the hydrogen can reach the critical speed in the nozzle under various working conditions and reach the induction But the adjustment needle 1001 needs an additional motor to drive, which introduces problems such as extra power consumption and noise, and the response is delayed, so it cannot quickly meet the needs of load changes. In addition, due to the small nozzle, the eccentricity of the adjustment needle 1001 setting The error is high and the use is unstable.

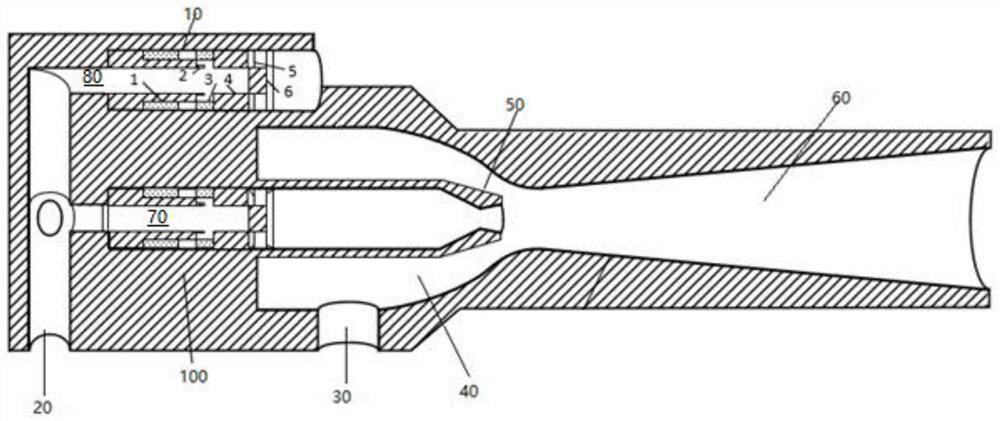

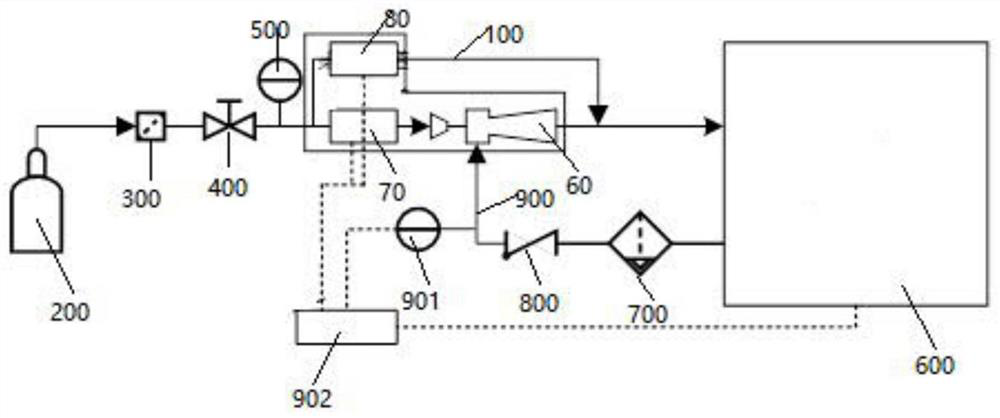

[0047] In view of this, the embodiment of this application provides an integrated ejector, please refer to figure 2 , the integrated ejector 100 is used with the stack 600 of the fuel cell ( image 3 shown in ), the integrated ejector 100 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com