Coal mine rock roadway shoulder corner coal stripping device applied to TBM (Tunnel Boring Machine)

A roadheader and shoulder angle technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve problems such as unsatisfactory, and achieve the effect of convenient transportation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

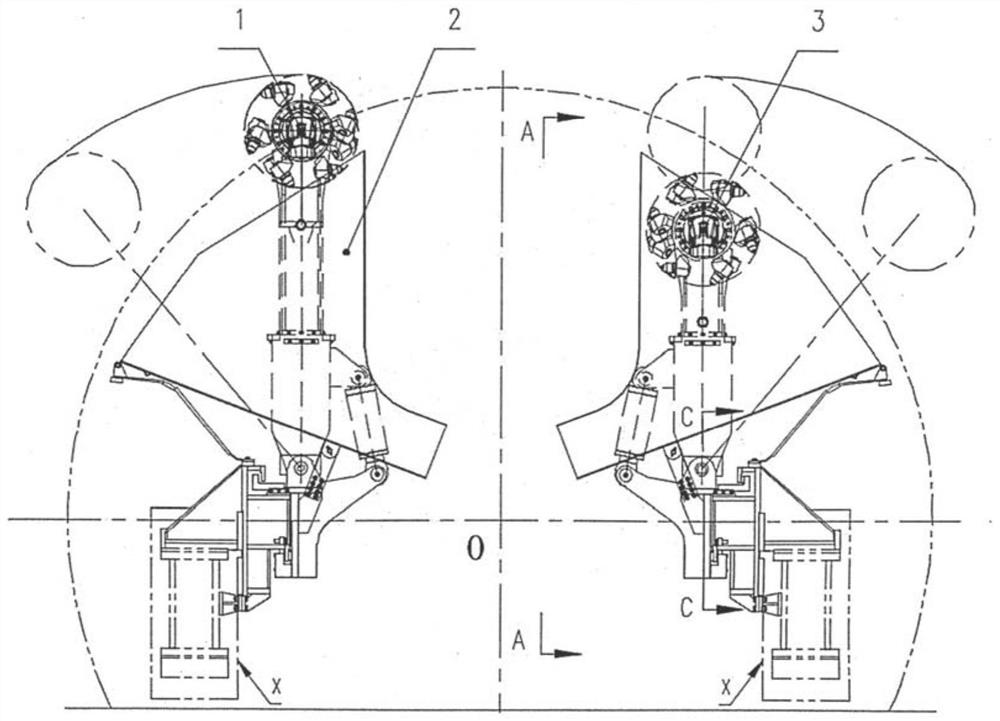

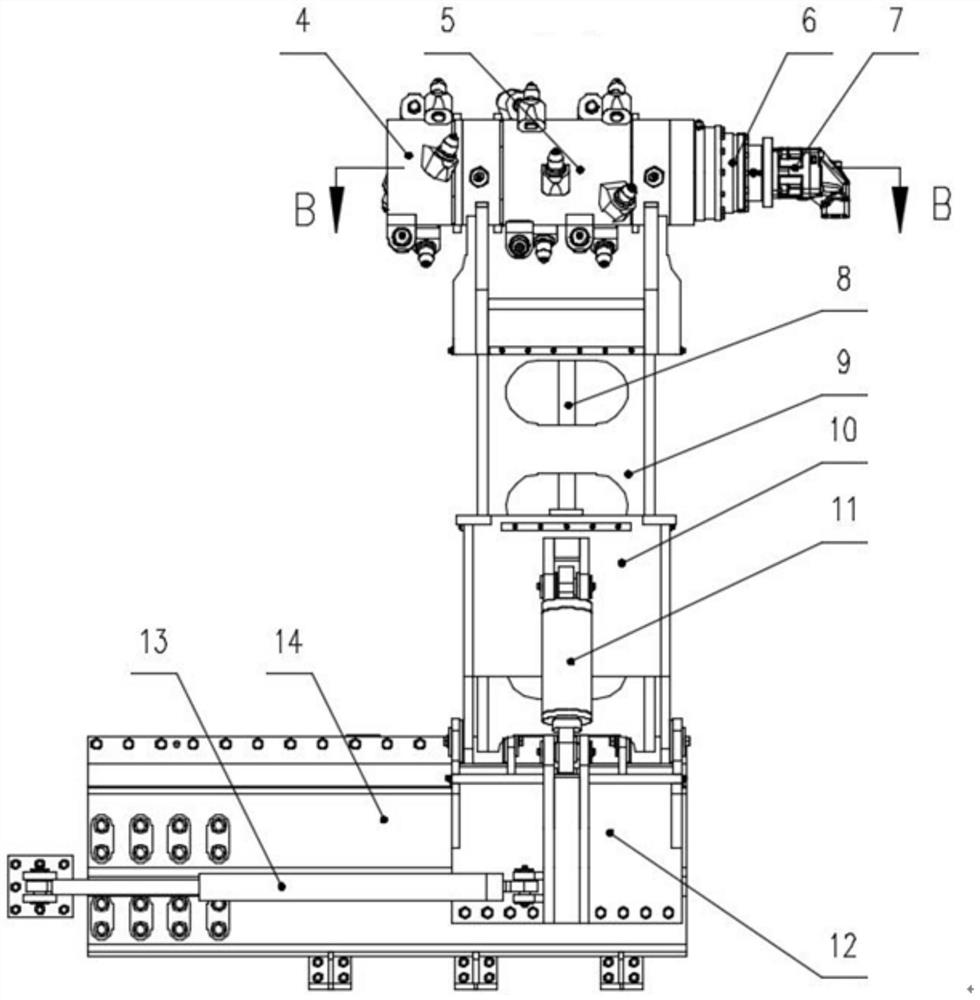

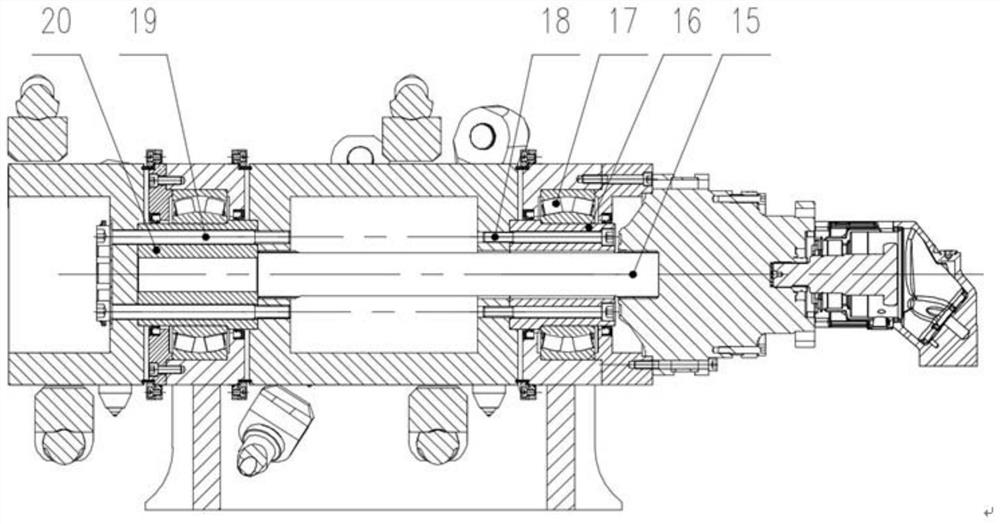

[0029] figure 1 The middle O represents the center of the tunnel. like Figure 1-5 As shown, the present invention includes a left shoulder angle coal peeling mechanism 1, a blanking collector 2, a right shoulder angle coal peeling mechanism 3, a small cutting drum 4, a large cutting drum 5, a hydraulic motor 6, a reducer 7, and a telescopic oil cylinder 8. Internal slideway 9, external sleeve 10, swing cylinder 11, horizontal movement seat 12, translation cylinder 13, horizontal movement track 14, spline shaft 15, left bearing support 16, self-aligning bearing 17, first high-strength bolt 18. The second high-strength bolt 19, the right bearing support 20, the bushing group 21, the swing pin 22, the telescopic pin 23, the left shoulder angle coal peeling device 1 and the right shoulder angle coal peeling device 3 are symmetrical in structure, respectively Arranged on both sides of the main beam X of the TBM roadheader, the blanking collector 2 is symmetrically arranged on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com