Method and system for measuring diameter and projection height of cylinder based on linear structured light

A technology of linear structured light and measurement method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of low detection efficiency, low measurement result accuracy, large deviation, etc., to improve measurement accuracy, reduce measurement workload, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

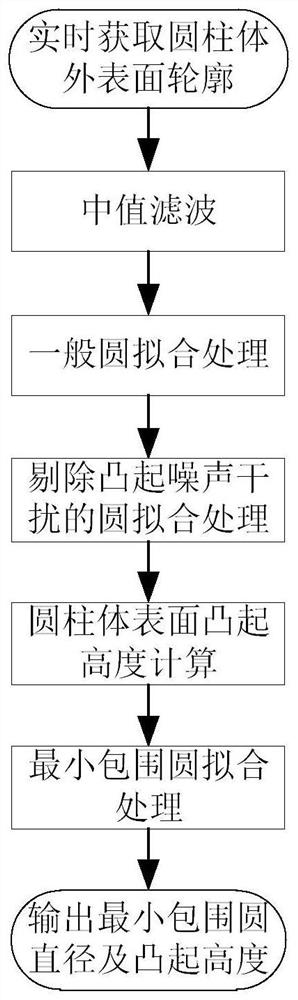

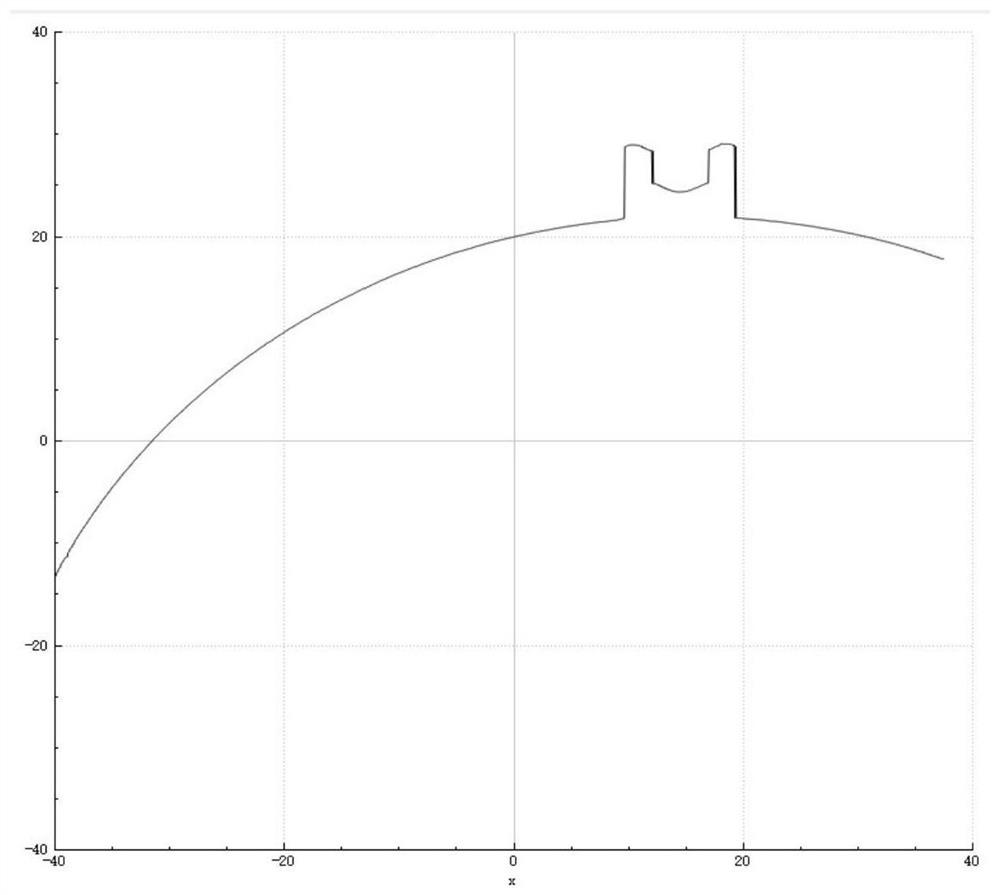

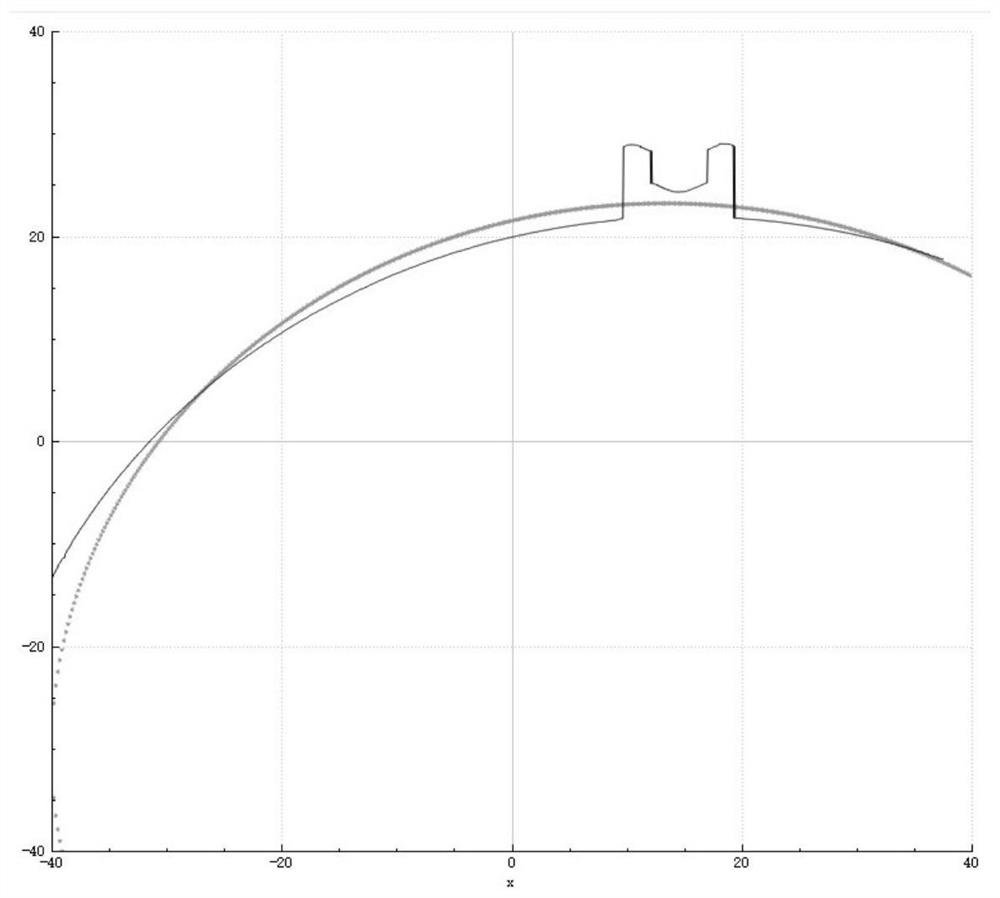

[0066] combine figure 1 A method for measuring cylinder diameter and surface protrusion based on line structured light, comprising the following steps:

[0067] First adjust the line structured light to be perpendicular to the centerline of the cylinder, and the line laser can move freely along the centerline of the workpiece to collect data, including the following steps:

[0068] Step a, fixing the cylindrical workpiece;

[0069] Step b. Turn on the line laser to acquire sensor data in real time;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com