Semiconductor structure and forming method thereof

A technology of semiconductor and gate structure, which is applied in the field of semiconductor structure and its formation, can solve the problems of semiconductor structure reliability to be improved, and achieve the effect of reducing the risk of short circuit, reducing the impact, and improving the etching selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]As mentioned in the background, the reliability of existing semiconductor structures still needs to be improved.

[0042] The reason why the reliability of the semiconductor structure still needs to be improved will be described in detail below with reference to the accompanying drawings.

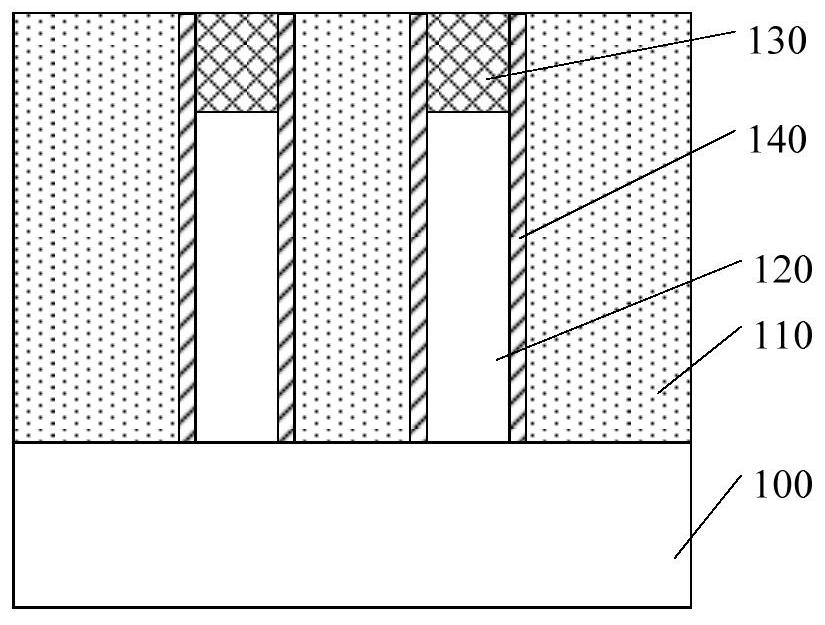

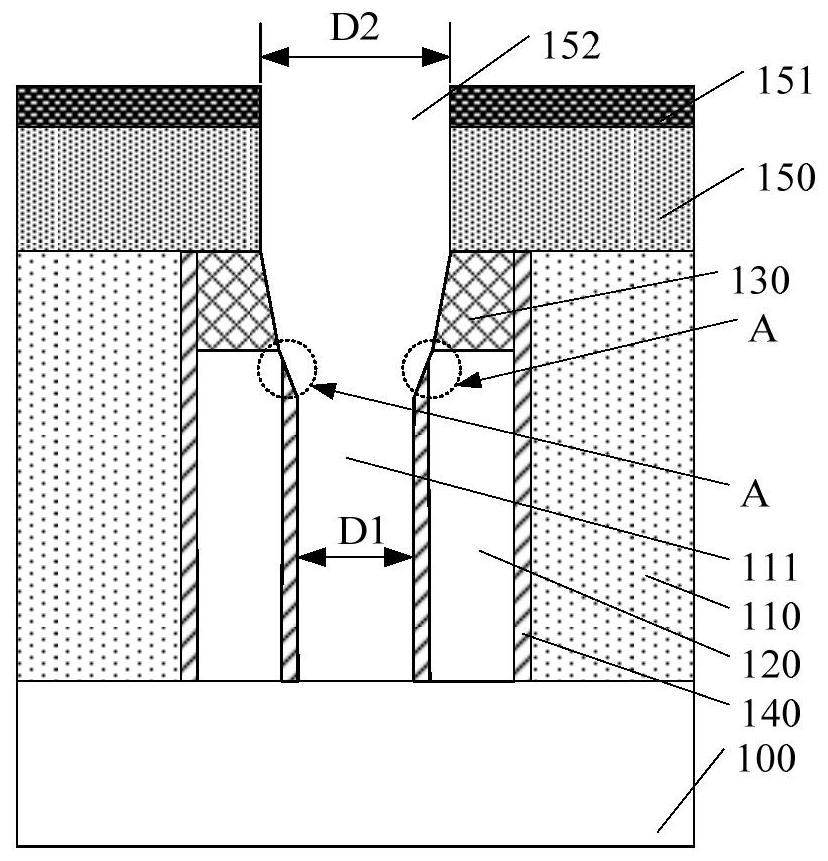

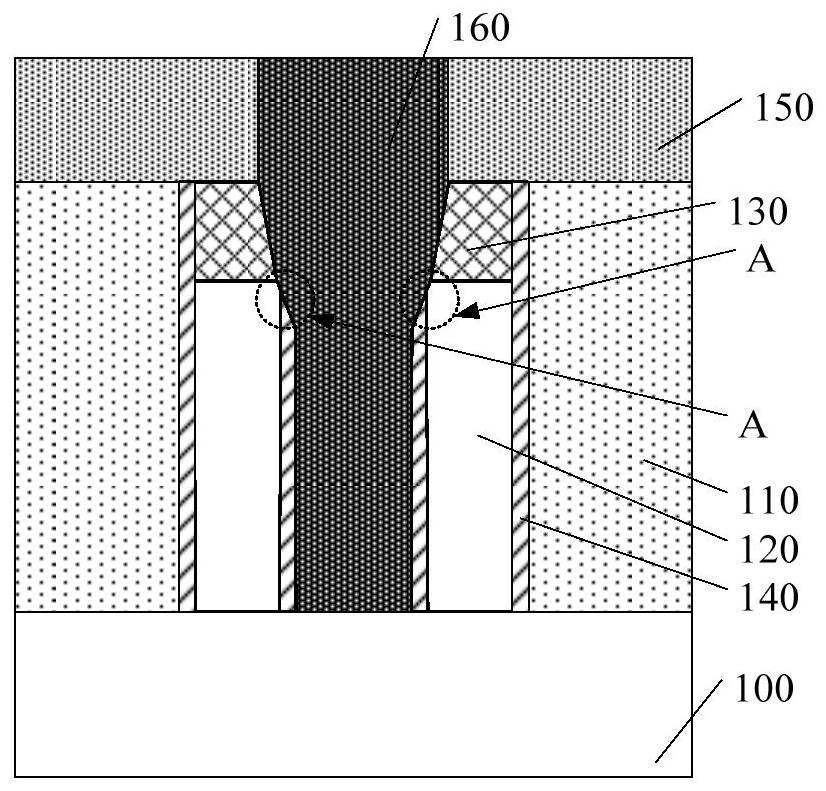

[0043] Figure 1 to Figure 3 It is a structural schematic diagram of each step of a method for forming a semiconductor structure.

[0044] Please refer to figure 1 , providing a substrate 100, the substrate 100 includes a substrate (not shown), and a plurality of fin structures (not shown) located on the substrate separated from each other; a first dielectric layer (not shown) is formed on the surface of the substrate 100 shown), the first dielectric layer covers part of the side wall of the fin structure.

[0045] Please continue to refer figure 1 , forming a second dielectric layer 110 on the surface of the first dielectric layer, the second dielectric layer 110 has a plurality...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap