Living mushroom production process

A production process and technology of shiitake mushrooms, applied in horticulture, mushroom cultivation, agriculture, etc., can solve the problems of insufficient number of mushrooms, easy to fall, and inability to evenly cover mushroom sticks, etc., to achieve shortened mushrooming cycle and economic benefits Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

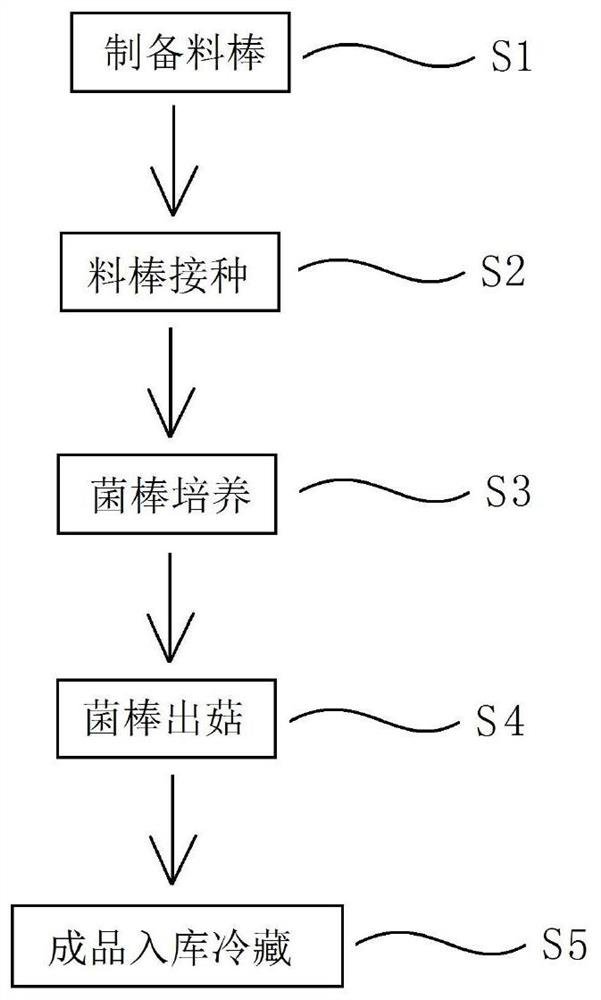

[0050] Live shiitake mushroom production process, such as figure 1 shown, including the following steps:

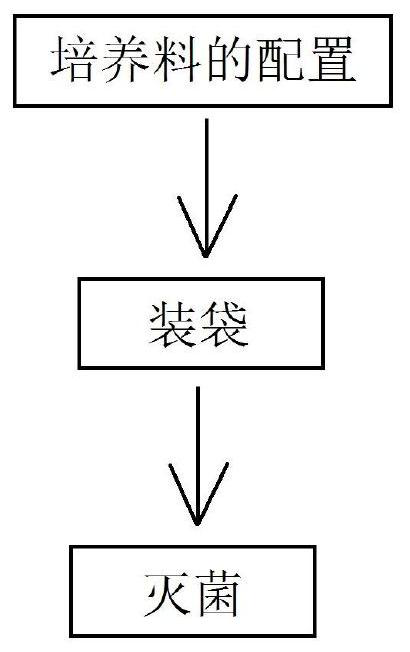

[0051] S1, preparation rod, such as figure 2 shown, including:

[0052] 1) Configuration of compost:

[0053] 78 parts by weight of sawdust, 20 parts of bran, and 1 part of gypsum were stirred and mixed for 10 minutes, then water was added, and after stirring was continued for 30 minutes, a compost for live shiitake mushrooms was made, and the water content of the compost was 60 wt %;

[0054] Sawdust is fermented before use: the selected wood chips have a particle size diameter of 7-9mm, and the content of oak wood chips in the wood chips is ≥50wt%. Turn the pile in 3-5 days, and water continuously during the fermentation process to keep the sawdust moist;

[0055] 2) Bagging: Put the prepared culture material into the fungus bag to obtain a standard-sized material rod. The material rod is cylindrical, with a length of 21cm, a diameter of 9.7cm, and a weight of abou...

Embodiment 2

[0073] Live shiitake mushroom production process, such as figure 1 shown, including the following steps:

[0074] S1, preparation rod, such as figure 2 shown, including:

[0075] 1) Configuration of compost:

[0076] 70 parts by weight of sawdust, 25 parts of bran, and 0.5 part of gypsum were stirred and mixed for 10 minutes, then water was added, and after stirring was continued for 30 minutes, a compost for live shiitake mushrooms was made, and the water content of the compost was 55 wt %; The selection of sawdust and the fermentation process are the same as in Example 1;

[0077] 2) Bagging: Put the prepared culture material into the fungus bag to obtain a standard-sized material rod. The material rod is cylindrical, with a length of 21cm, a diameter of 9.7cm, and a weight of about 1.08kg. The tightness is suitable and there is no broken bag micropore. , the mouth is intact;

[0078] 3) Sterilization: transfer the rod into a high-temperature sterilizer for high-temper...

Embodiment 3

[0095] Live shiitake mushroom production process, such as figure 1 shown, including the following steps:

[0096] S1, preparation rod, such as figure 2 shown, including:

[0097] 1) Configuration of compost:

[0098] 74 parts by weight of sawdust, 18 parts of bran, and 2 parts of gypsum were stirred and mixed for 5 minutes, then water was added, and after stirring was continued for 30 minutes, the compost of live shiitake mushrooms was made, and the water content of the compost was 65 wt %; The selection of sawdust and the fermentation process are the same as in Example 1;

[0099] 2) Bagging: Put the prepared culture material into the fungus bag to obtain a standard-sized material rod. The material rod is cylindrical, with a length of 21cm, a diameter of 9.7cm, and a weight of about 1.08kg. The tightness is suitable and there is no broken bag micropore. , the mouth is intact;

[0100]3) Sterilization: transfer the rod into a high-temperature sterilizer for high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com