High-performance wear-resistant part extrusion forming device based on truck container

A technology of extrusion molding and containers, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low safety, hand injury, extrusion, etc., to improve safety, facilitate follow-up operations, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

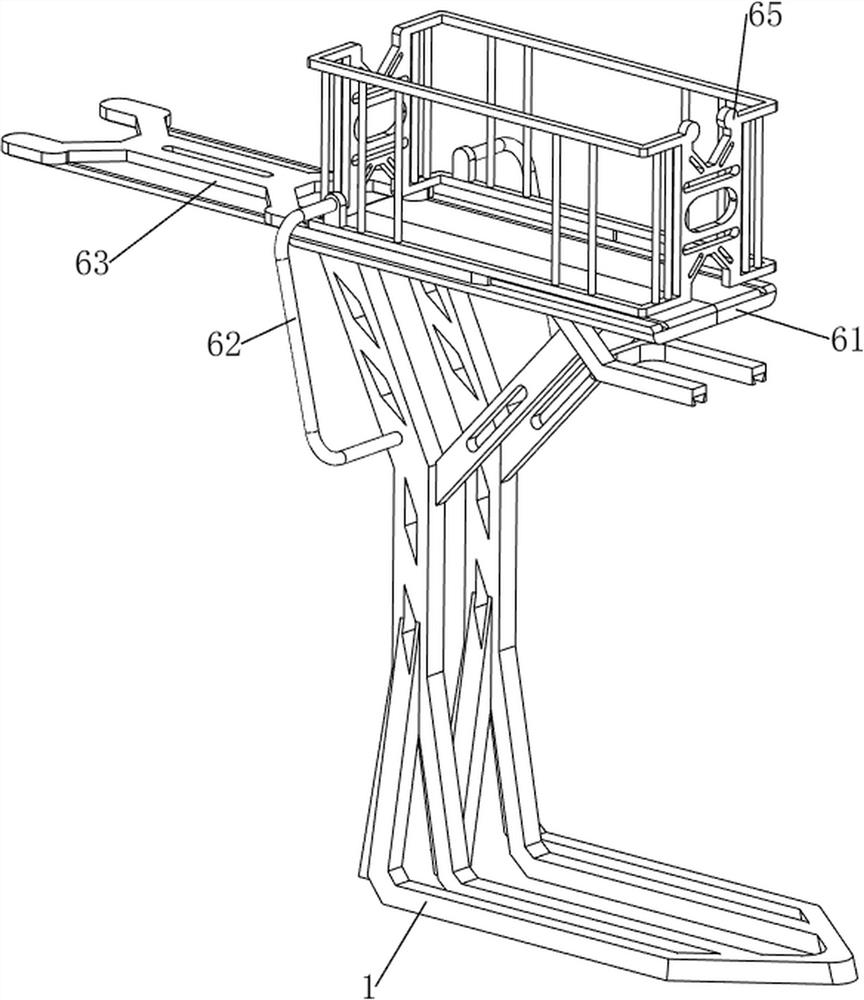

[0042] An extrusion molding device for high-performance wear-resistant parts based on truck containers, such as Figure 1-6As shown, it includes a first support frame 1, a forming plate 2, an extruding block 3, a cylinder 4, an extruding mechanism 5 and a feeding mechanism 6, and the forming plate 2 is installed on the right side of the top of the first supporting frame 1, and the first support The left side of the top of the frame 1 is provided with a feeding mechanism 6. The feeding mechanism 6 is provided with an extruding mechanism 5. The extruding mechanism 5 is used to extrude the steel plate. The extruding mechanism 5 is equipped with a cylinder 4, and the bottom of the piston rod of the cylinder 4 The end is connected with an extrusion block 3, and the extrusion block 3 cooperates with the forming plate 2.

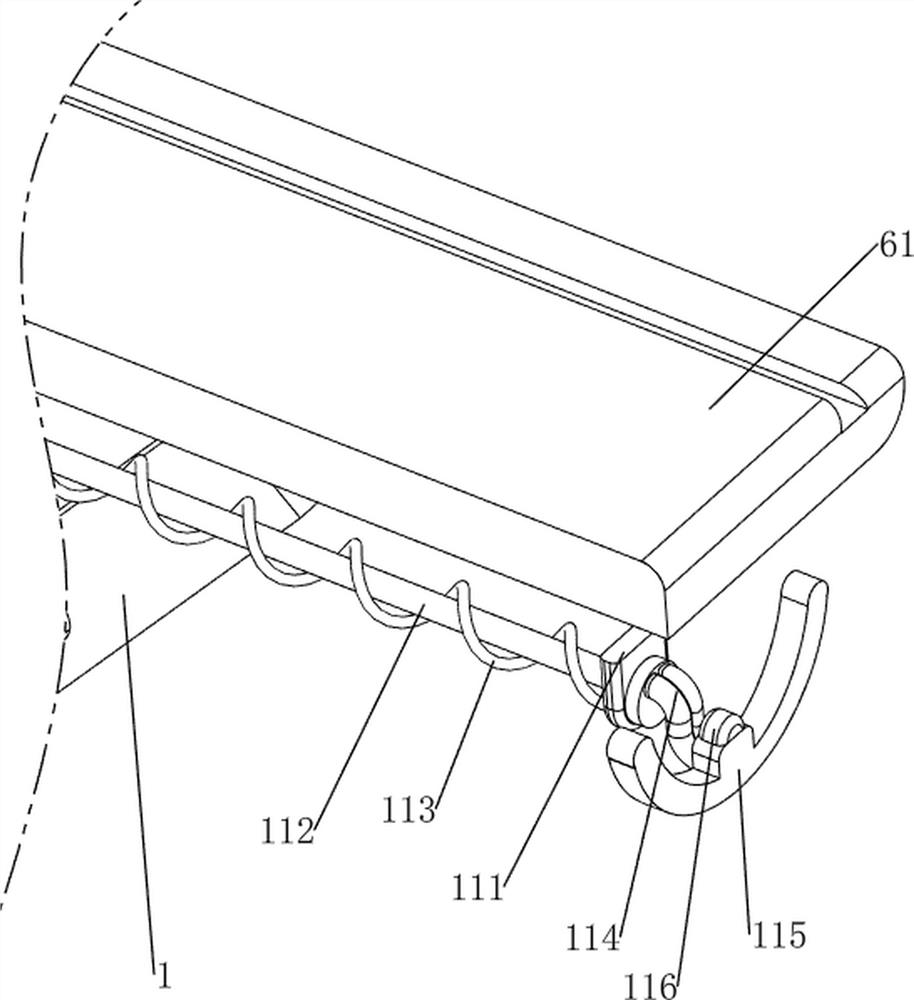

[0043] Such as Figure 1-6 As shown, the feeding mechanism 6 includes a mounting plate 61, a second mounting rod 62, a pushing plate 63, a slider plate 64 and a m...

Embodiment 2

[0049] On the basis of Example 1, such as figure 1 , figure 2 , Figure 8 , Figure 9 , Figure 11 and Figure 13 As shown, a limit mechanism 8 is also included, and the limit mechanism 8 is used to limit the steel plate that needs to be extruded. The limit mechanism 8 includes a fixed rod 81, a connecting rod 82, a first return spring 83, a limit Plate 84 and touch rod 85, two fixed rods 81 are installed on the right side of the bottom of the forming board 2, the two fixed rods 81 are front and rear symmetrical, and a connecting rod 82 is installed on the top of the fixed rod 81, and the sliding connection between the two connecting rods 82 Limiting plate 84, the connecting rod 82 is covered with a first back spring 83, the top of the first back spring 83 is connected with the limiting plate 84, the limiting plate 84 can prevent the steel plate that needs to be extruded from moving excessively to the right, the first The return spring 83 is connected, and the front and ...

Embodiment 3

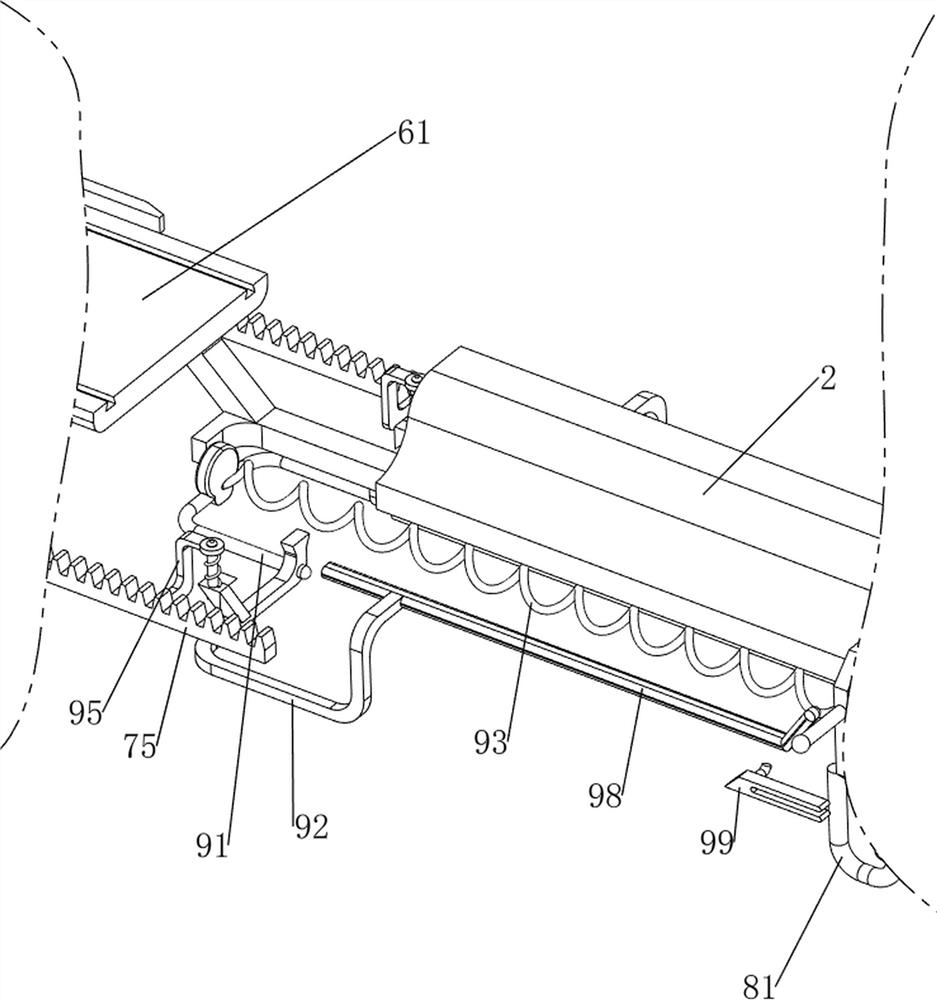

[0052] On the basis of Example 2, such as figure 1 , figure 2 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, the pressing mechanism 9 is also included, and the pressing mechanism 9 is used to move the limit plate 84 downward to loosen the extruded steel plate. The pressing mechanism 9 includes a second support frame 91, a slider frame 92, The second return spring 93, the first wedge 94, the second fixed plate 95, the telescoping rod 96, the second wedge 97, the third wedge 98 and the fourth wedge 99, the front and rear sides of the bottom of the forming plate 2 are sliding A slider frame 92 is connected, a second support frame 91 is installed between the left sides of the two slider frames 92, and a second return spring 93 is connected between the right side of the second support frame 91 and the bottom right side of the forming plate 2, The third wedge-shaped block 98 is installed on the inner side of the slider frame 92, and the third wedge-shaped bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com