Pneumatic drill jig capable of being quickly assembled and disassembled

A jig-drilling and fast technology, applied in the direction of the jig-drilling used for the workpiece, etc., can solve the problems of high man-hour cost of machine tools, time-consuming turning and positioning, and uneconomical cost, etc., to achieve convenient clamping, good product consistency, and clamping Convenient and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

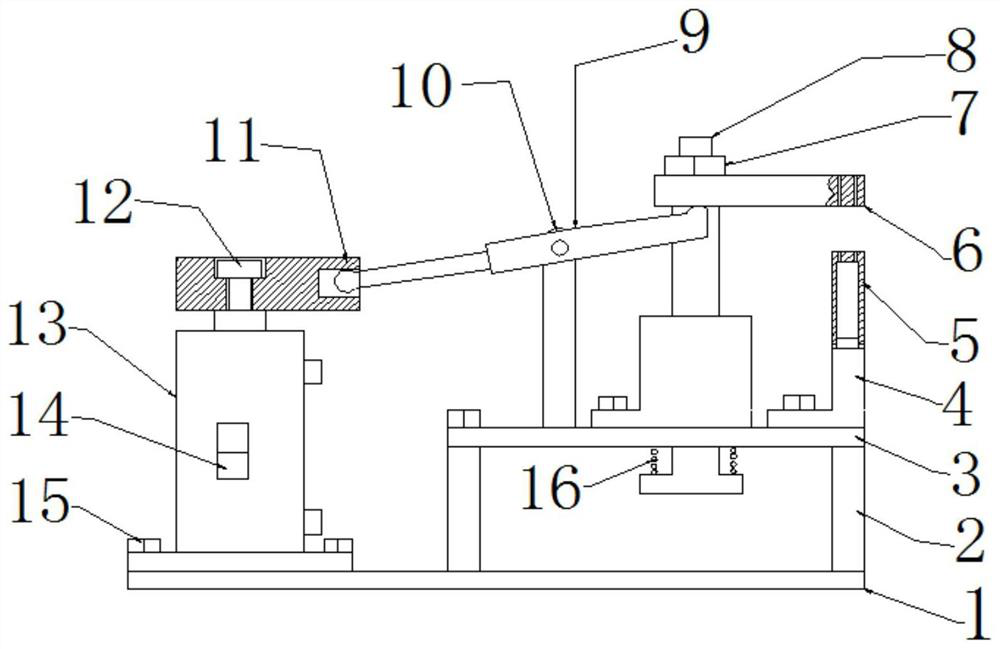

[0037] This embodiment provides a pneumatic fast loading and unloading drilling mold, its structure is as follows figure 1 As shown, it includes a clamp body 1, a support base 3 fixed on the clamp body 1, a positioning support 4 and a movable support rod 8 arranged on the support base 3, and a drilling template 6, and the top of the positioning support 4 is placed to be processed. The workpiece 5, the movable support rod 8 has a degree of freedom to move in the direction perpendicular to the support seat 3, the drilling template 6 is fixedly installed on the top of the movable supporting rod 8, and the drilling template 6 is also processed with a drilling template guide hole facing the workpiece 5 .

[0038] see you again figure 1 As shown, the support base 3 is arranged on the clamp body 1 through the support plate 2, and a space is reserved between the support base 3 and the clamp body 1, so that the movable support rod 8 can be conveniently moved on the support base 3 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com