Extruder for manufacturing composite particles for efficiently shielding neutron gamma radiation

A technology of gamma radiation and composite particles, which is applied in the field of extruders, can solve the problems of single uniform cooling, inconvenient and efficient fine mixing, and inconvenient extrusion of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

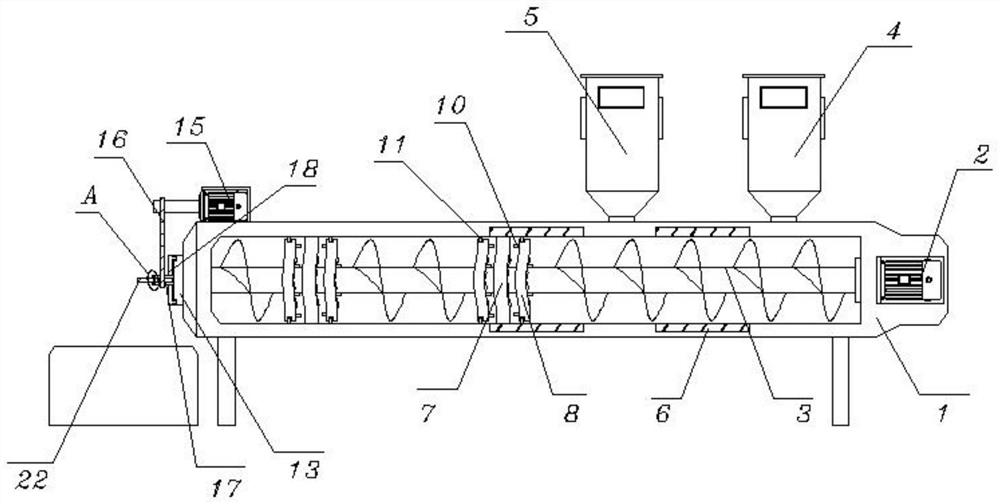

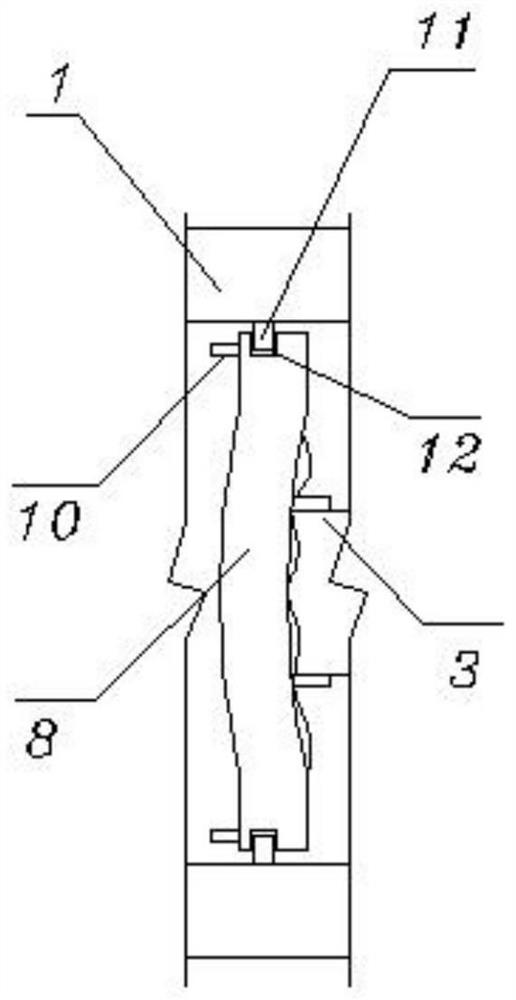

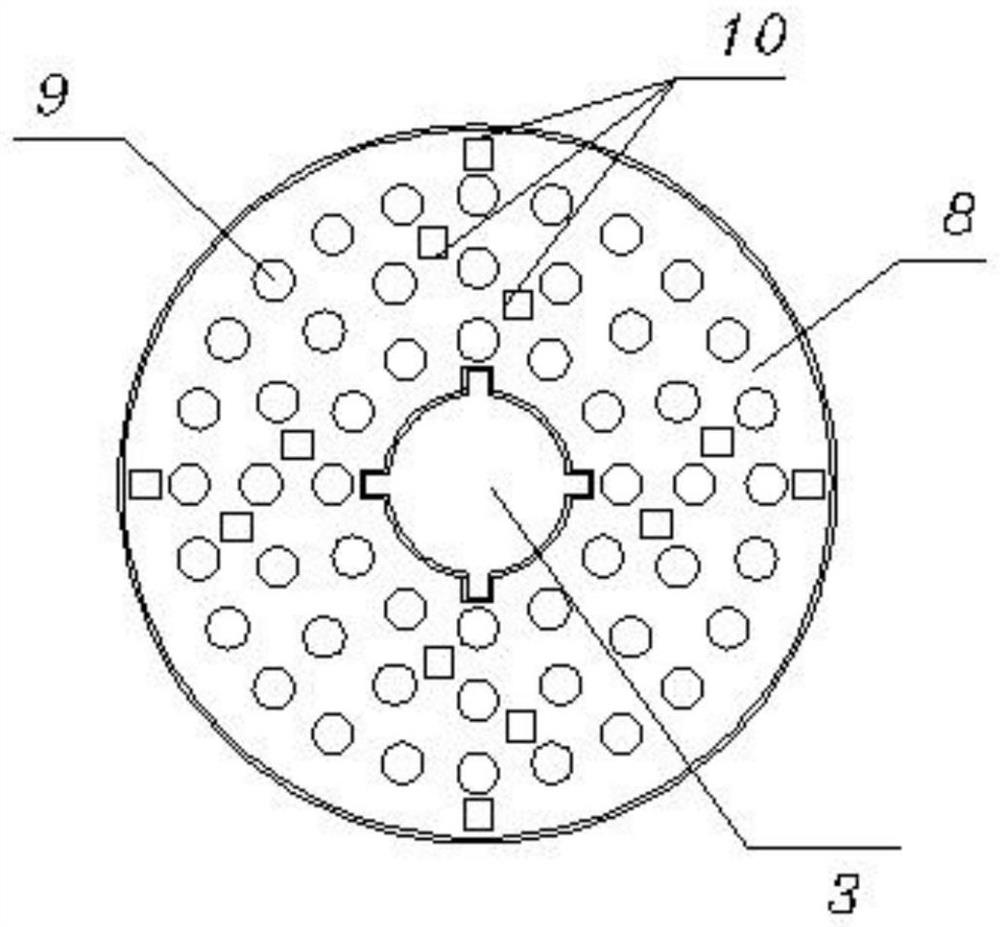

[0033] see Figure 1-4 , including a frame 1, one end of the frame 1 is embedded with a first motor 2, and the output end of the first motor 2 is connected with a screw propulsion rod 3, and the screw propulsion rod 3 is installed in the frame 1, and the frame 1 The first feed hopper 4 and the second feed hopper 5 are fixed through the top of the frame, and a heater 6 is installed on the inner wall of the frame 1; it also includes: a fixed material guide plate 7, which is fixed on the frame 1 On the inner wall of the fixed guide disc 7, movable guide discs 8 are arranged on both sides of the fixed guide disc 7, and the movable guide discs 8 are sleeved on the screw propulsion rod 3, and the fixed guide discs 7 and the movable guide discs 8 have an equal angle Correspondingly, a mixing hole 9 is provided, and a stirring plate 10 is fixed at an equal angle on the side of the movable material guiding plate 8, and the stirring plate 10 is close to the side of the fixed material gu...

Embodiment 2

[0035] see figure 1 and Figure 5-9 , extruding disc 13, extruding disc 13 is installed on the other end of frame 1, and extruding disc 13 is provided with extruding hole 14, and the outer bearing of extruding disc 13 is equipped with movable shaft 17, and on the movable shaft 17 Be connected with the output end of the second motor 15 by synchronous belt 16, and second motor 15 is fixed on the top edge place of frame 1, is fixed with material cutting cover 18 on the movable shaft 17, and the bottom of material cutting cover 18 is fixed with The material cutting knife 19, and the material cutting knife 19 and the material cutting cover 18 fit together with the extrusion disk 13, the side of the material cutting cover 18 is provided with an entry groove 20, and one end of the material cutting cover 18 is located in the ring groove 21, And the ring groove 21 is offered on the extruding disk 13, and the edge end of the movable shaft 17 is penetrated with an air-flow conveying pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com