Casting blank self-stabilizing lifting device

A technology of casting billets and lifting shafts, which is applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of reduced billet safety, shortened chain service life, difficult and stable transportation of billets, etc., and achieves improved stability. performance, enhance the ability to withstand shock loads, and increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the invention are described in detail below in combination with the accompanying drawings, but the invention can be implemented in a variety of different ways.

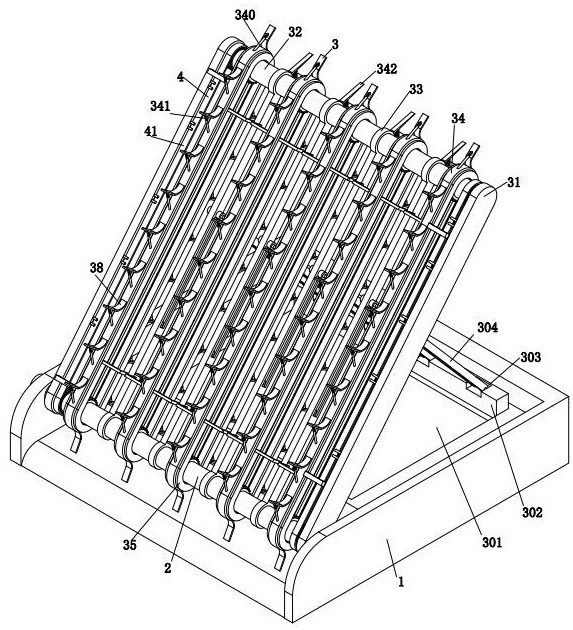

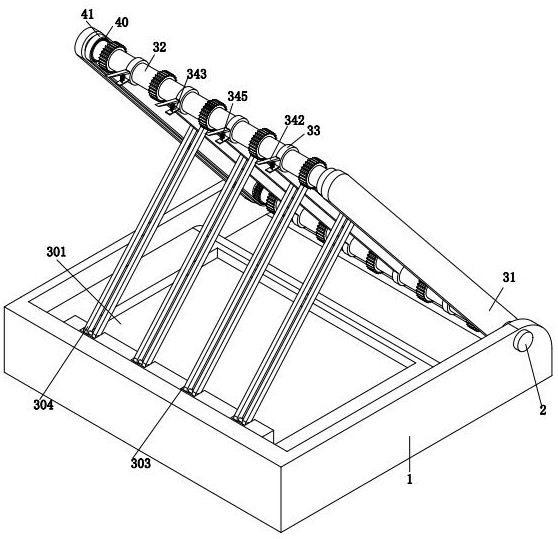

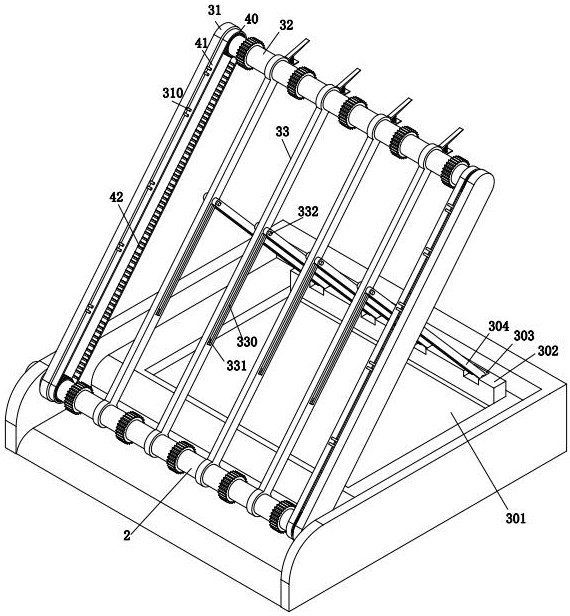

[0032] see Figure 1 A slab self stabilizing lifting device comprises a fixed base 1, a rotating shaft 2, a stabilizing lifting mechanism 3 and an anti reverse mechanism 4. The upper end face of the fixed base 1 is provided with a step groove, the left and right end faces of the step groove close to the front end are rotationally connected with a rotating shaft 2, a stabilizing lifting mechanism 3 is installed on the rotating shaft 2, and an anti reverse mechanism 4 is installed on the stabilizing lifting mechanism 3.

[0033] see Figure 1 、Figure 4 、 Figure 7 And Figure 8 The stable lifting mechanism 3 comprises a support connecting plate 31, the left and right sides of the rotating shaft 2 are sleeved with fixed sleeves 30, the two fixed sleeves 30 are rotationally connected with the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com