Bionic tooth type cutting tooth

A technology for cutting teeth and teeth, which is applied in the field of bionic tooth-type cutting teeth, can solve problems such as breaking and easy falling off, and achieve the effects of enhancing the fixing effect, increasing the contact area, and enhancing the cushioning capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

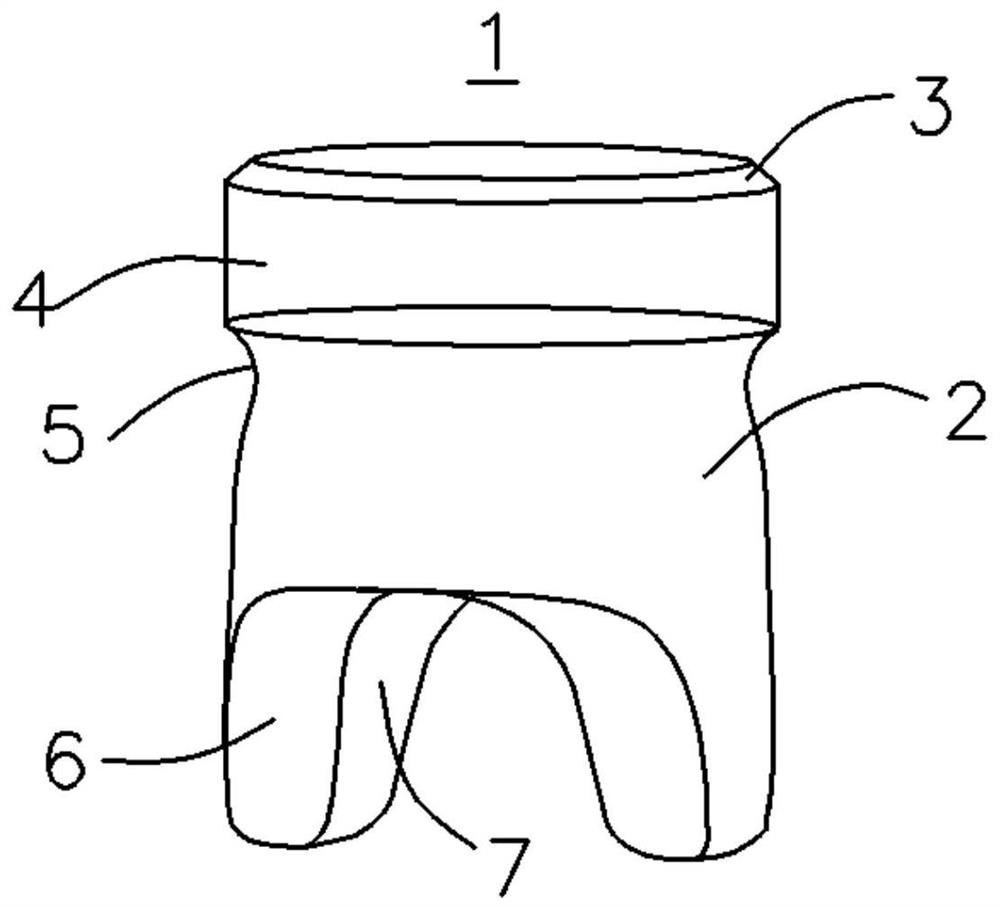

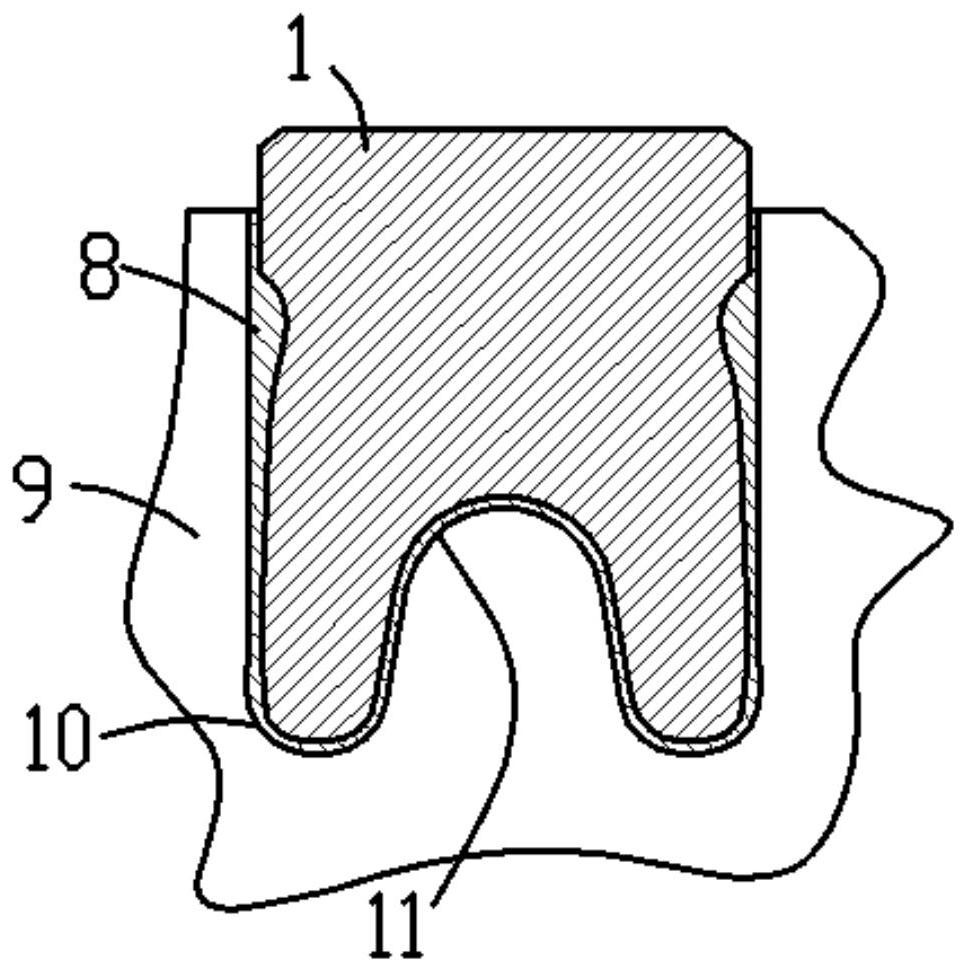

[0034] Please refer to figure 1 , with reference to figure 2 , the application provides a bionic tooth-type cutting tooth 1, which mainly includes a tooth-like body, the tooth-like body includes a base 2 made of hard alloy and a thin polycrystalline diamond layer 3 connected above the base 2, the polycrystalline diamond The diamond thin layer 3 is integrally formed with the base body 2, and the diameter of the polycrystalline diamond thin layer 3 gradually decreases from the point in contact with the base body 2 toward the direction away from the base body 2, and the thickness is relatively thin. At the same time, the base body 2 has a tooth-like structure, and the base body 2 includes a tooth crown 4, a tooth neck 5, and a plurality of protruding tooth roots 6 arranged at intervals from bottom to top, and a polycrystalline diamond thin layer 3 is arranged on the upper surface of the tooth crown 4 , the raised tooth root 6 is used to insert the positioning hole 10 in the fix...

no. 2 example

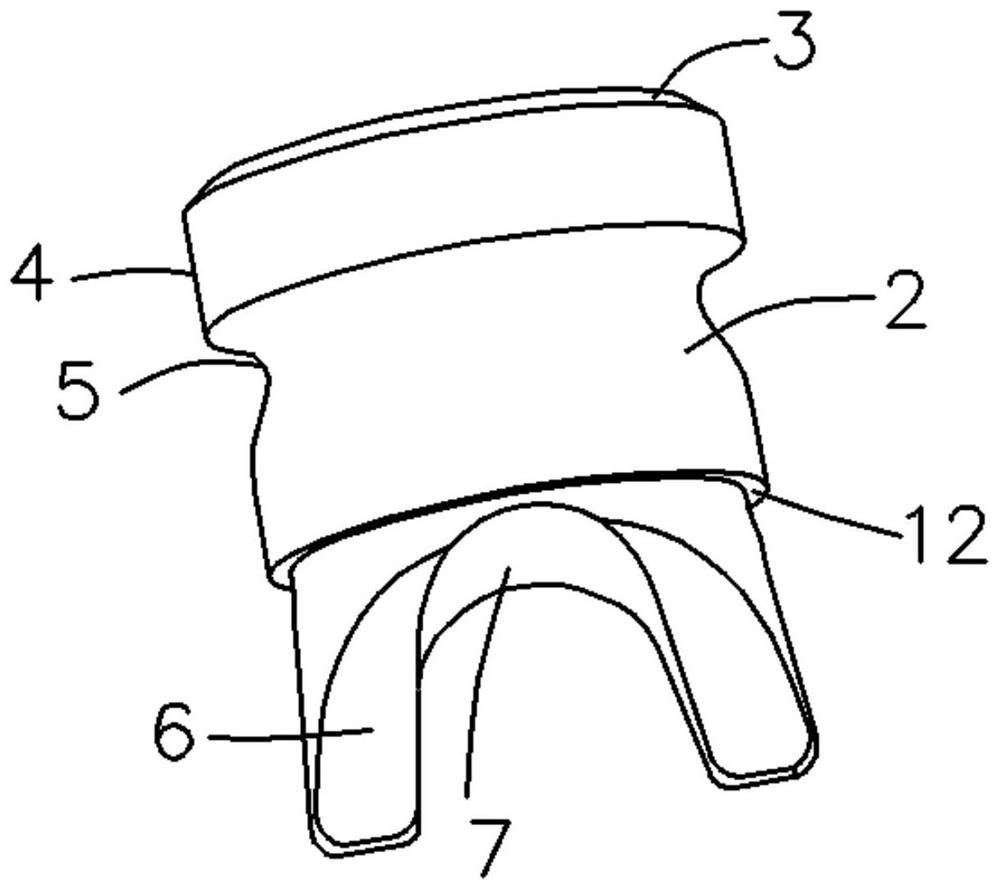

[0049] Please refer to image 3 , the present application provides a bionic tooth-type cutting tooth 1, the structure of which is substantially the same as that in the first embodiment, the difference is that in this embodiment, the distance between the two furthest protruding dedendums 6 is less than The diameter of the base body 2, that is, a transition step 12 is provided between the tooth-like body of the cutting tooth and the raised tooth root 6, so that the raised tooth root 6 part is smaller than the diameter of the tooth-like body, so that it protrudes during installation. The part of tooth root 6 can be completely protected by the fixed-tooth socket 9 on the blade of the drill bit, so as to prevent the cutting teeth from excessive contact with the external environment, which will cause the welding part to be subjected to excessive erosion during the cutting process, resulting in a decrease in bearing capacity, and further It can effectively improve the tooth fixing ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com