A long carbon fiber reinforced titanium alloy composite material

A technology of long carbon fiber and composite materials, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems affecting the normal use and appearance of materials, and surface corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

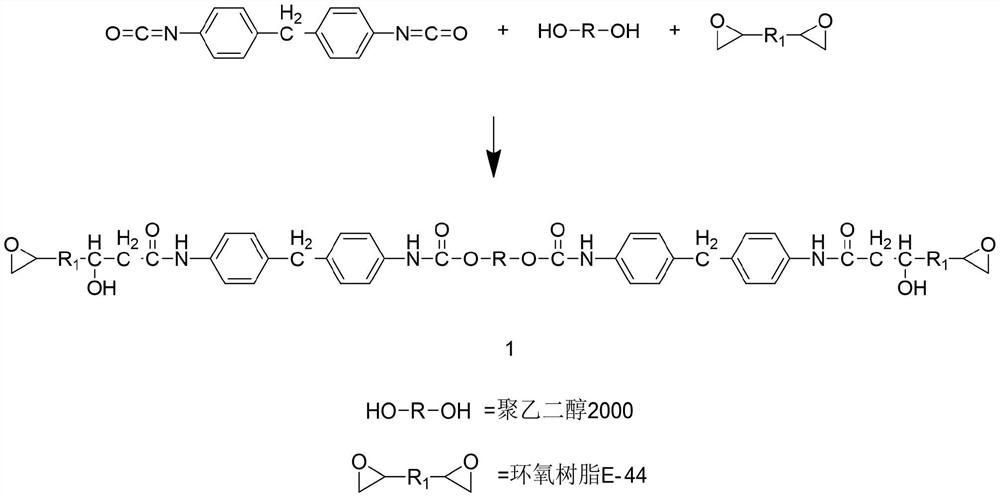

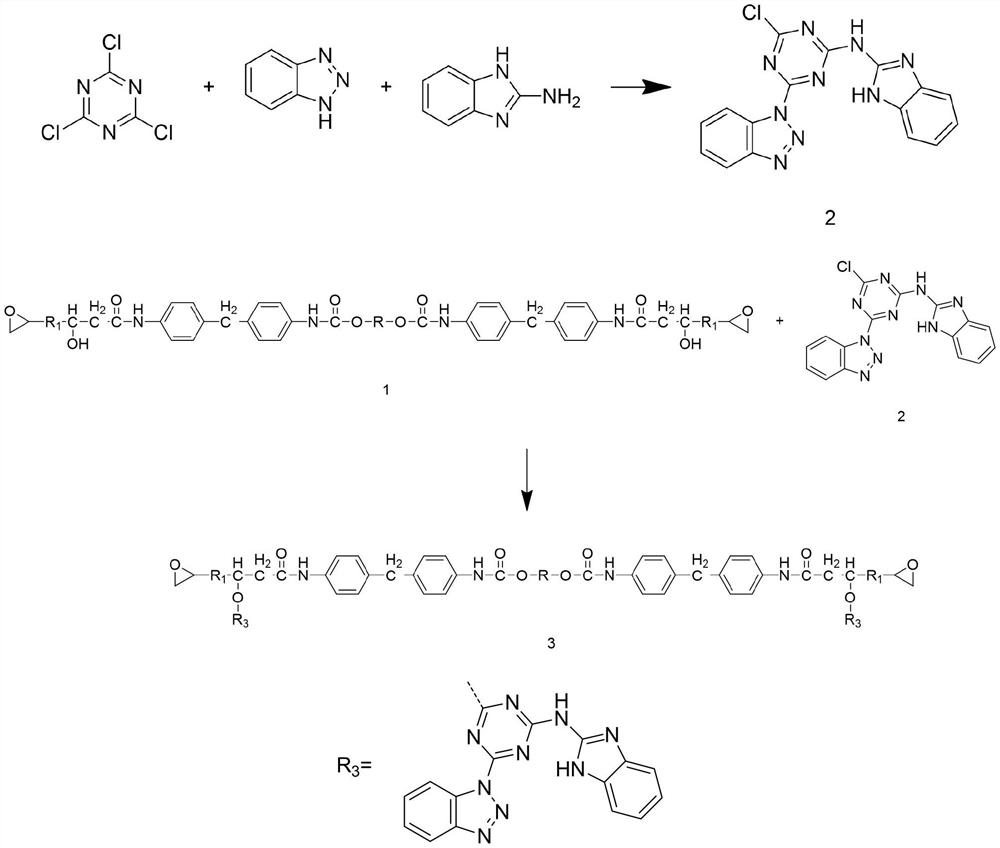

Method used

Image

Examples

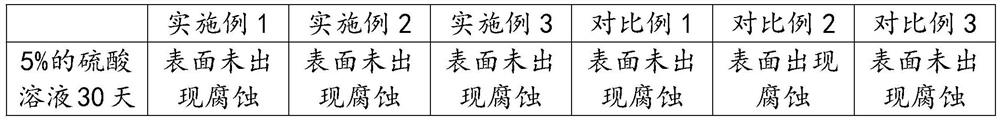

Embodiment 1

[0035] A long carbon fiber reinforced titanium alloy composite material is obtained by compounding modified long carbon fibers and titanium alloy powder, coating with a coating liquid, and then spraying with an anti-corrosion coating to prepare the long carbon fiber reinforced titanium alloy composite material.

[0036] The long carbon fiber reinforced titanium alloy composite material is made by the following steps:

[0037] Step S1: Lay the titanium alloy powder evenly in the mold with a thickness of 2cm, and then lay the modified long carbon fiber on the titanium alloy powder, and then lay a layer of titanium alloy powder until the mold is filled. Under the condition of 600MPa, after holding the pressure for 1min, under the condition of 1000℃, sintering for 5h, the composite plate was obtained;

[0038] Step S2: Immerse the composite sheet in the coating liquid, after soaking for 20 s, pull out the composite sheet, hang vertically for 3 min, add it into the muffle furnace, ...

Embodiment 2

[0052] A long carbon fiber reinforced titanium alloy composite material is obtained by compounding modified long carbon fibers and titanium alloy powder, coating with a coating liquid, and then spraying with an anti-corrosion coating to prepare the long carbon fiber reinforced titanium alloy composite material.

[0053] The long carbon fiber reinforced titanium alloy composite material is made by the following steps:

[0054] Step S1: Lay the titanium alloy powder evenly in the mold with a thickness of 3 cm, then lay modified long carbon fibers on the titanium alloy powder, and then lay a layer of titanium alloy powder until the mold is filled, at a temperature of 160 ° C, pressure Under the condition of 630MPa, after holding the pressure for 1.3min, under the condition of 1100℃, sintering for 6h, the composite plate was obtained;

[0055] Step S2: Immerse the composite sheet in the coating liquid, after soaking for 25s, pull out the composite sheet, hang it vertically for 4 m...

Embodiment 3

[0069] A long carbon fiber reinforced titanium alloy composite material is obtained by compounding modified long carbon fibers and titanium alloy powder, coating with a coating liquid, and then spraying with an anti-corrosion coating to prepare the long carbon fiber reinforced titanium alloy composite material.

[0070] The long carbon fiber reinforced titanium alloy composite material is made by the following steps:

[0071] Step S1: Lay the titanium alloy powder evenly in the mold with a thickness of 4cm, and then lay the modified long carbon fiber on the titanium alloy powder, and then lay a layer of titanium alloy powder until the mold is filled. Under the condition of 650MPa, after holding the pressure for 1.5min, under the condition of 1200℃, sintering for 7h, the composite plate was obtained;

[0072] Step S2: Immerse the composite sheet in the coating solution, after soaking for 30s, pull out the composite sheet, hang vertically for 5 minutes, add it to the muffle furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com