Tunnel kiln

A tunnel kiln and furnace body technology, applied in the kiln field, can solve problems such as difficult fixing of kiln car, lower product firing quality, increase embryo body separation from heating area, etc., and achieve the effect of improving firing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-7 The application is described in further detail.

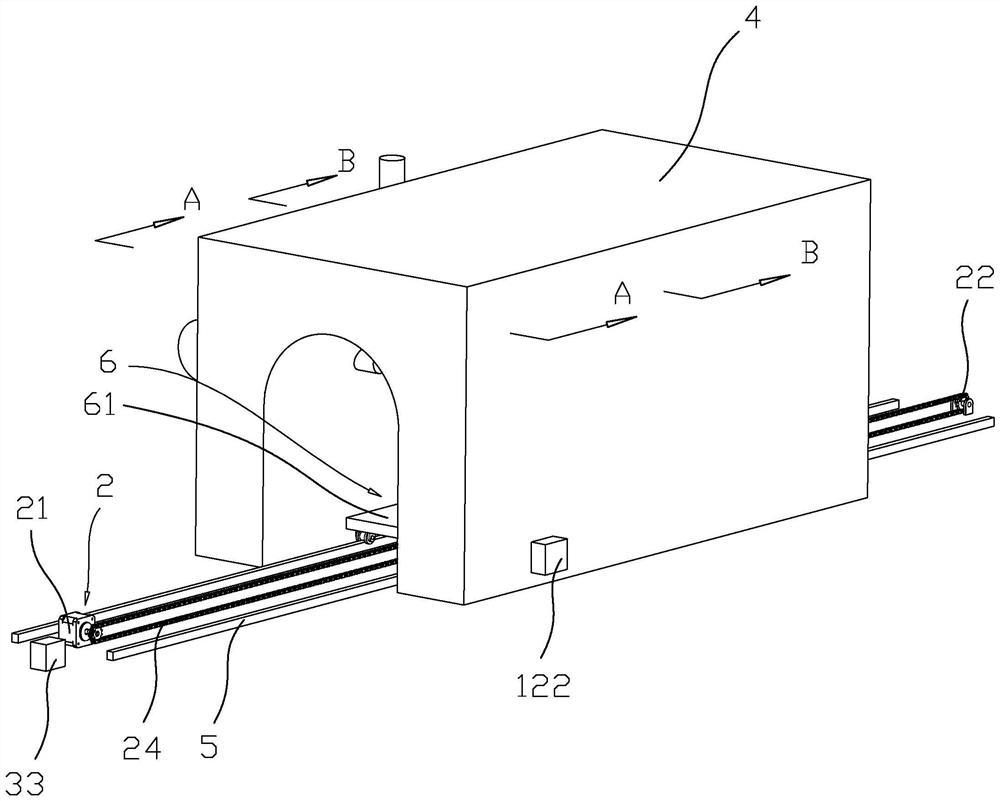

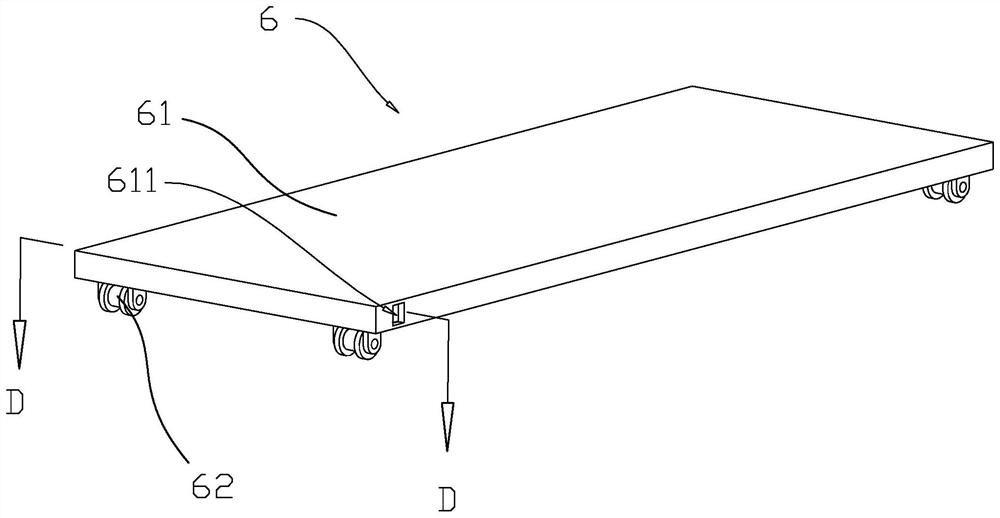

[0037] The embodiment of the present application discloses a tunnel kiln. refer to figure 1 and figure 2 As shown, the tunnel kiln includes a furnace body 4 , a track 5 , a kiln car 6 , a locking mechanism 1 , a driving mechanism 2 and a control mechanism 3 . The track 5 is laid on the ground in the furnace body 4, the kiln car 6 includes a bearing plate 61 and rollers 62, the bearing plate 61 is horizontally arranged above the track 5, and the rollers 62 are arranged on the bottom surface of the bearing plate 61 to rotate and there are four, four Two rollers 62 are respectively located at the four corners of the bearing plate 61 , and the rollers 62 are rollingly arranged on the track 5 .

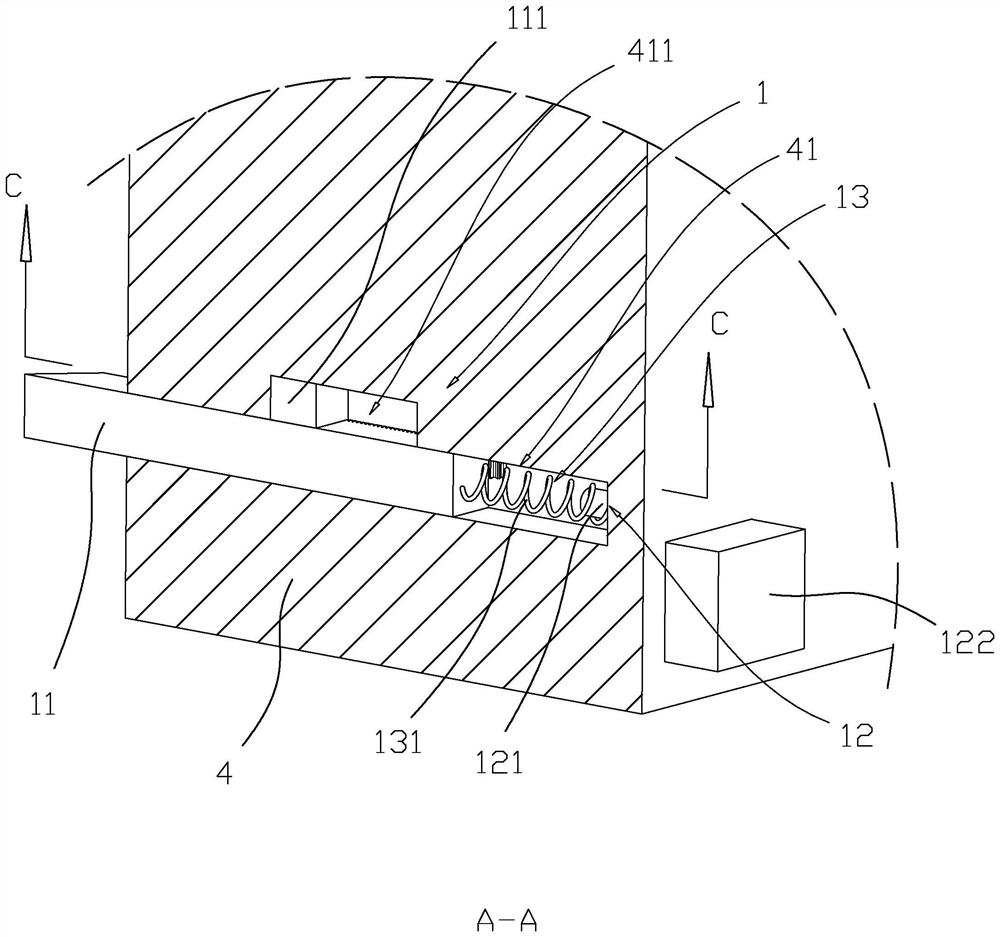

[0038] refer to figure 2 and image 3 As shown, the locking mechanism 1 includes a locking lever 11 , a pulling component 12 and a pushing component 13 . The inner side wall of the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com