Corrugated board compressive strength testing device

A technology of compressive strength and corrugated board, applied in the field of corrugated board, can solve the problems of uneven test force, reduce test effect, single test structure, etc., to avoid corrosion, improve test effect, and ensure the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

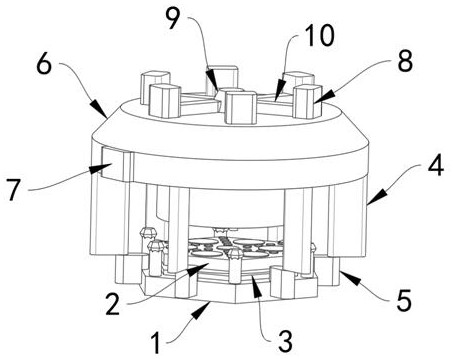

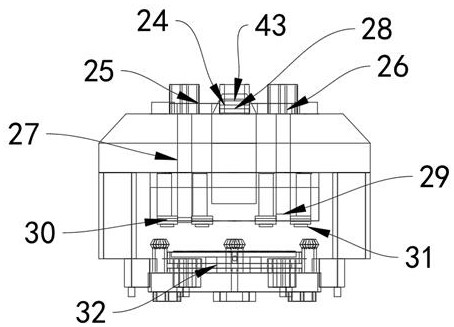

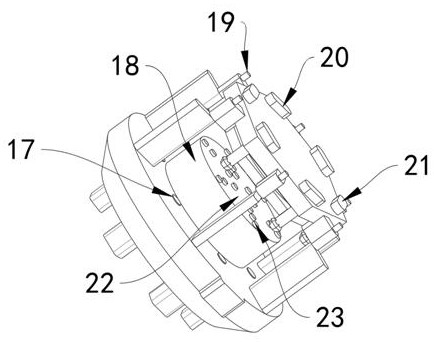

[0026] see Figure 1-5 , an embodiment provided by the present invention: corrugated cardboard compressive strength testing device, comprising a circular shock-absorbing chassis 1, six electric telescopic rods 4 are arranged on the upper and outer sides of the circular shock-absorbing chassis 1, and the upper ends of the electric telescopic rods 4 A test disc 6 is provided, an information terminal 9 is arranged above the test disc 6, a pressure column 18 is provided at the lower end of the test disc 6, and six form recognition columns 12 are provided above the circular shock-absorbing chassis 1, and the circular shock-absorbing The mutual cooperation of the shock cha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap