Resistance reducing and dust collecting device for eddy current probe

A technology of dust collection and eddy current probe, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of manual collection of radioactive dust, high radiation, increased eddy current inspection speed, and low eddy current inspection speed, so as to achieve radioactive dust collection, The effect of increasing the speed of eddy current inspection and reducing the impact on body safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

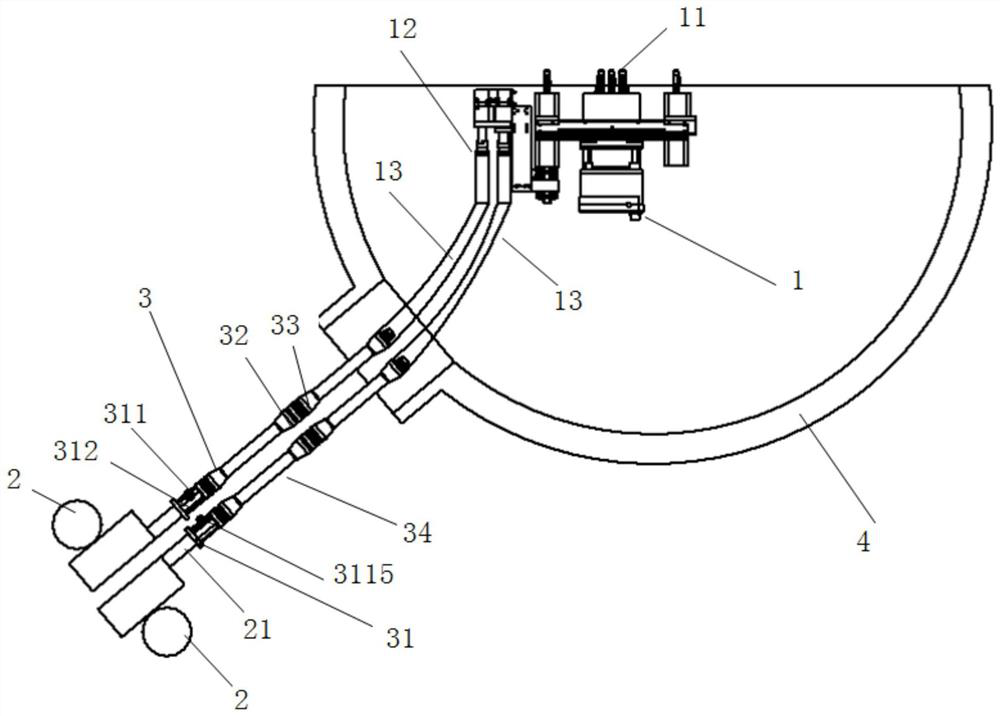

[0028] see figure 2 , the present invention provides an eddy current probe drag reduction and dust collection device, comprising a probe positioning system 1, a probe pusher 2 and a drag reduction and dust collection device main body 3; one end of the drag reduction and dust collection device main body 3 is connected to a probe for positioning System 1, the other end of the main body 3 of the drag reduction and dust collection device is connected to the probe pusher 2, and the eddy current probe is installed in the main body 3 of the drag reduction and dust collection device.

[0029] Working principle: The probe pusher 2 drives the eddy current probe to the probe positioning system 1, and the probe positioning system 1 drives the eddy current probe to move to the nozzle of the heat transfer tube; the main body 3 of the drag reduction and dust collection device reduces the resistance of the eddy current probe transmission, and collects at the same time radioactive dust.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com