Mechanical installation assistive device with power-assisted lifting function

A mechanical and auxiliary technology, used in manufacturing tools, workbenches, workshop equipment, etc., can solve the problems of difficult installation of fuel tanks and high labor intensity of installation, and achieve the goal of reducing labor intensity, reducing the number of workers, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

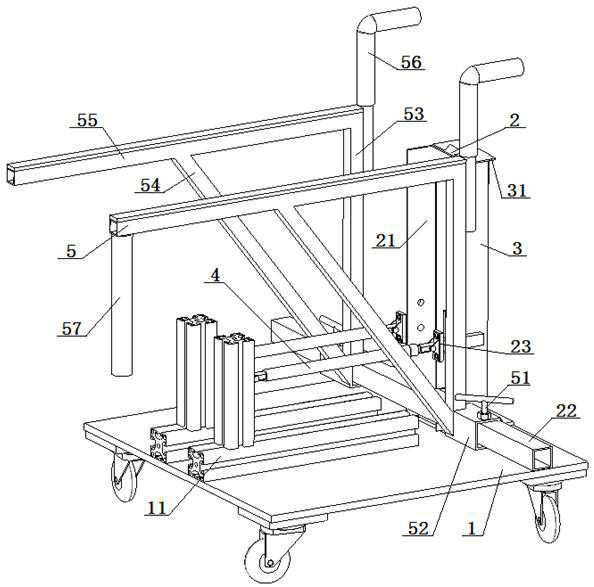

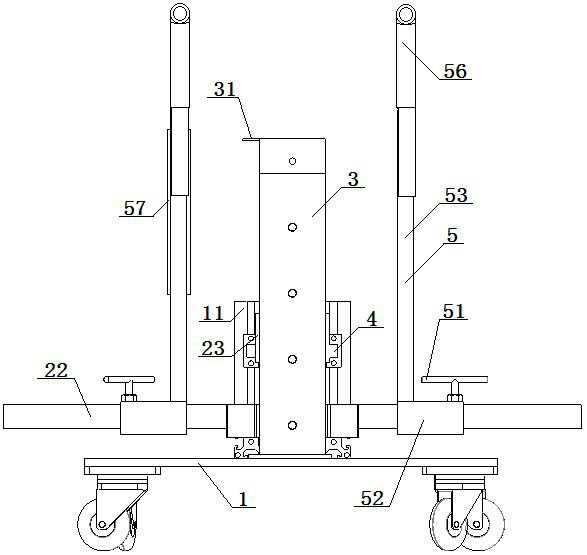

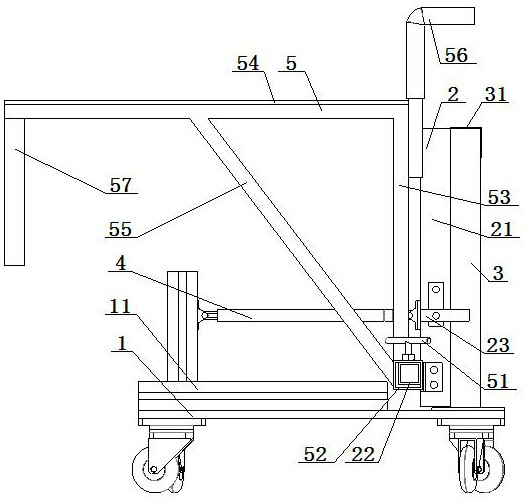

[0046]A mechanical lifting installation aid with power assistance, the installation aid includes: a flat trolley 1 and a lifting bracket 2, the lifting bracket 2 is fixed on the flat trolley 1 through a fixing seat 3, the lifting bracket 2 and the fixed The seat 3 is slidingly fitted; the lifting support 2 is connected with the flat trolley 1 through the gas spring 4; the lifting support 2 includes a lifting slide rail frame 21 and a lower fixed beam 22, and the lower end of the lifting slide rail frame 21 is fixed to the lower The crossbeam 22 is vertically connected, the bottom of the lifting slide rail frame 21 is space-limitingly matched with the top surface of the flat trolley 1, the back of the lifting slide rail frame 21 is slidingly fitted with the fixing seat 3, and the middle and lower part of the lifting slide rail frame 21 passes through The gas spring 4 is connected with the flat trolley 1; an adjustable width tripod 5 is respectively set on both sides of the lower...

Embodiment 2

[0048] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0049] Both sides of described lifting slide rail frame 21 are respectively fixedly connected with a spring fixing seat 23, and described flat trolley 1 top is provided with two spring fixing brackets 11, and described two spring fixing brackets 11 are arranged in parallel, and described two The spring fixing bracket 11 is relatively arranged with the fixing seat 3, and each of the two spring fixing brackets 11 is connected with the spring fixing seat 23 by a gas spring 4, and one end of the gas spring 4 is rotatably matched with the spring fixing bracket 11, so that The other end of the gas spring 4 is rotatably engaged with the spring holder 23, and the two gas springs 4 are arranged in parallel.

Embodiment 3

[0051] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0052] The back of described lifting slide rail frame 21 is provided with the slide rail that cross-section is isosceles trapezoid, and described slide rail is slidably matched with the chute on the fixed seat 3; The top of described fixed seat 3 is provided with upper limit plate 31, so The upper limit plate 31 and the spring fixing seat 23 limit fit; the top of the vertical rod 53 is fixedly connected with a handle 56; one end of the storage rod 54 is fixedly connected with the handle 56, and the other end of the storage rod 54 is fixedly connected Leading rod 57 is arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com