Cleaning type vacuum resin hole plugging machine

A resin-plugged, clean-type technology, applied in the positioning of circuit board tools, printed circuits, electrical components, etc., can solve problems such as pollution and oily surfaces, to ensure precise fit, reduce complex processes, and improve convenience and adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

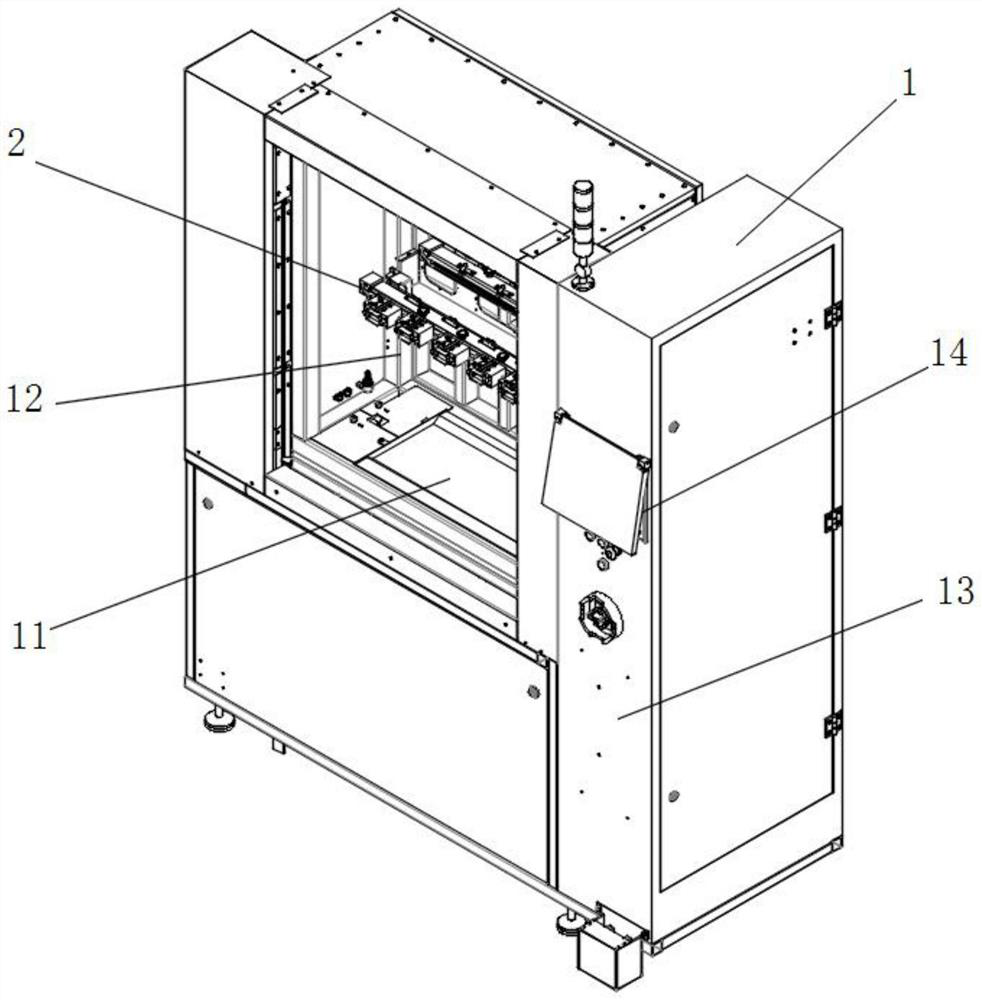

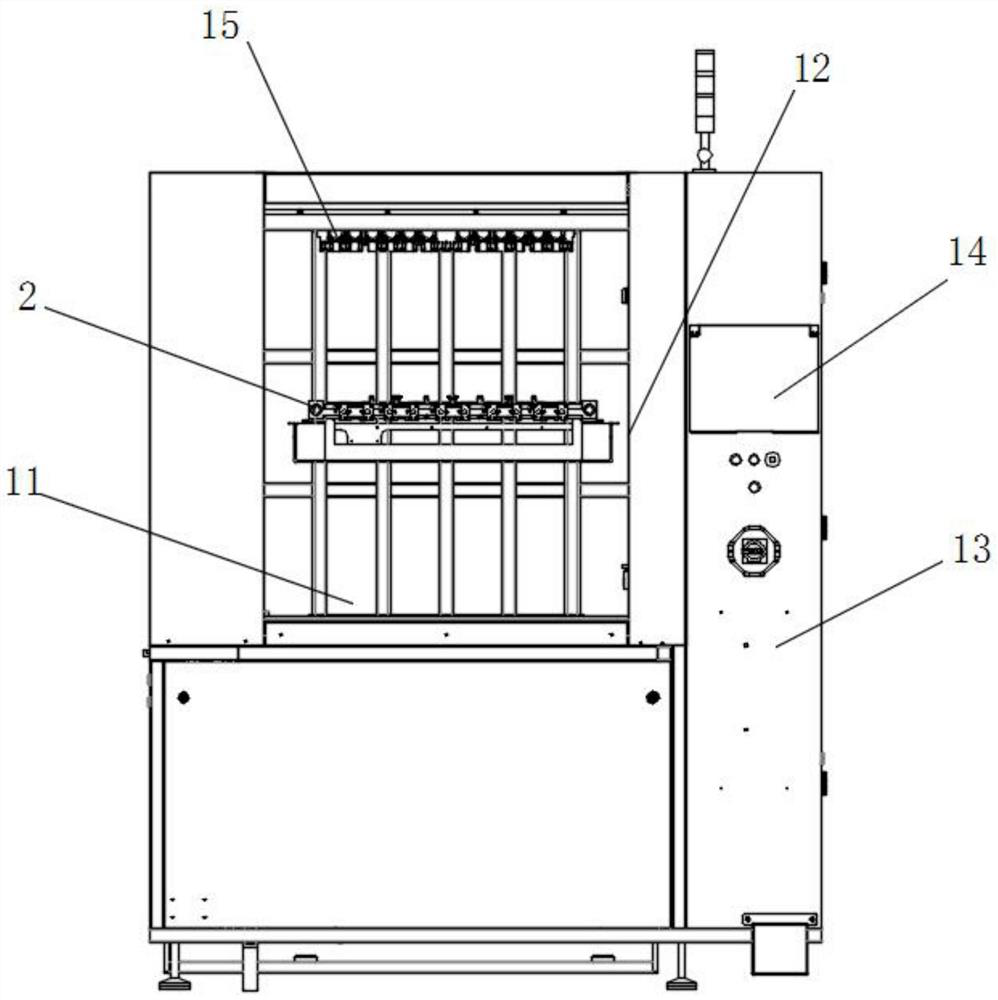

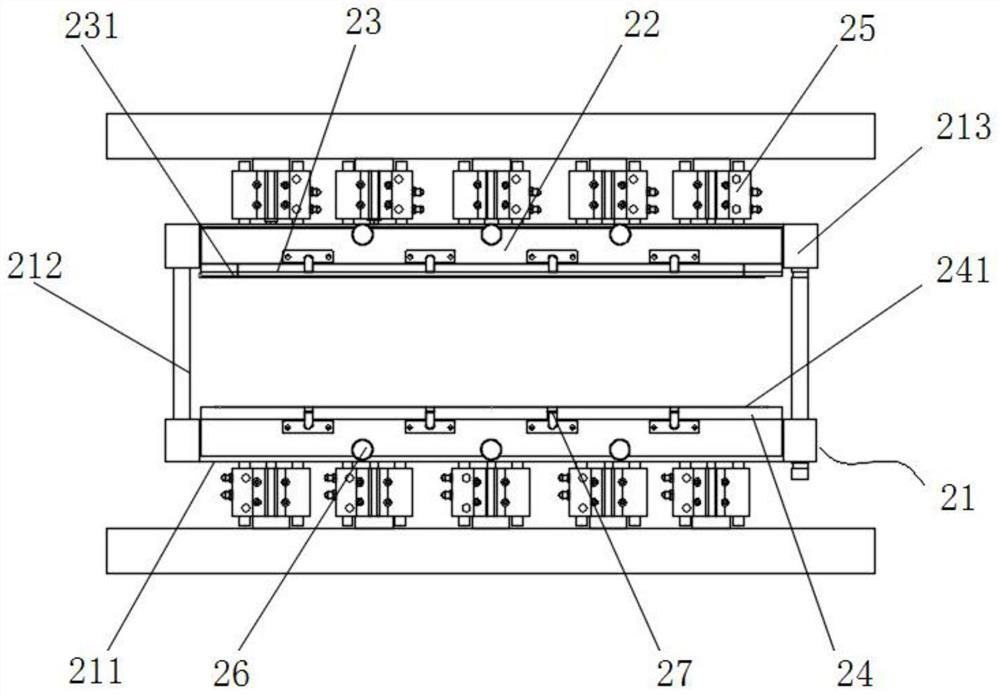

[0028] The present invention provides such as Figure 1-6 A clean vacuum resin plugging machine shown includes a body 1, the inside of which is provided with a vacuum chamber body 11, the vacuum chamber body 11 is provided with a sealed chamber door, and the top of the vacuum chamber body 11 A splint seat 15 is fixedly installed, and the inside of the vacuum chamber body 11 is provided with a plug module 2 that can lift and slide. The plug module 2 includes a module frame 21 and two sets of plug bases 22. The plug bases 22 are respectively detachably mounted on both sides of the module frame 21, and the two groups of plug bases 22 are driven to slide in opposite directions by translational drive equipment, and the two groups of plug bases 22 are respectively fixedly installed with a front plug head 23 and a rear plug head 24, a single-strand seal 231 is installed on the outside of the front plug head 23, a double-strand seal 241 is installed on the outside of the rear plug hea...

Embodiment 2

[0034] Such as Figure 3-5 A clean vacuum resin plugging machine shown includes a body 1, the inside of which is provided with a vacuum chamber body 11, the vacuum chamber body 11 is provided with a sealed chamber door, and the top of the vacuum chamber body 11 A splint seat 15 is fixedly installed, and the inside of the vacuum chamber body 11 is provided with a plug module 2 that can lift and slide. The plug module 2 includes a module frame 21 and two sets of plug bases 22. The plug bases 22 are respectively detachably mounted on both sides of the module frame 21, and the two groups of plug bases 22 are driven to slide in opposite directions by translational drive equipment, and the two groups of plug bases 22 are respectively fixedly installed with a front plug head 23 and a rear plug head 24, a single-strand seal 231 is installed on the outside of the front plug head 23, a double-strand seal 241 is installed on the outside of the rear plug head 24, and the The inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com