High-flatness wrinkle-preventing copper foil laminating device

A coating device and flatness technology, which is applied in the field of copper foil coating devices, can solve the problems of copper foil folds, creases, and excessive tension of copper foil, so as to prevent the arrangement from being too large or too small and ensure consistency The effect of stability and guarantee of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

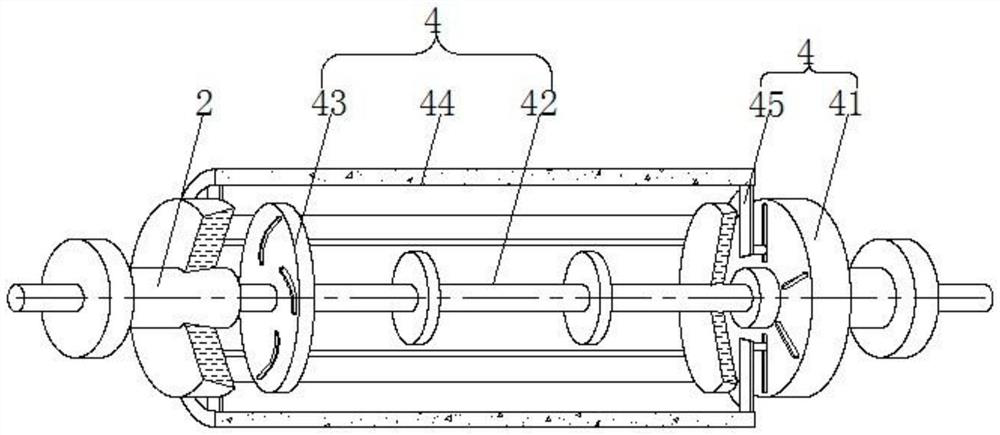

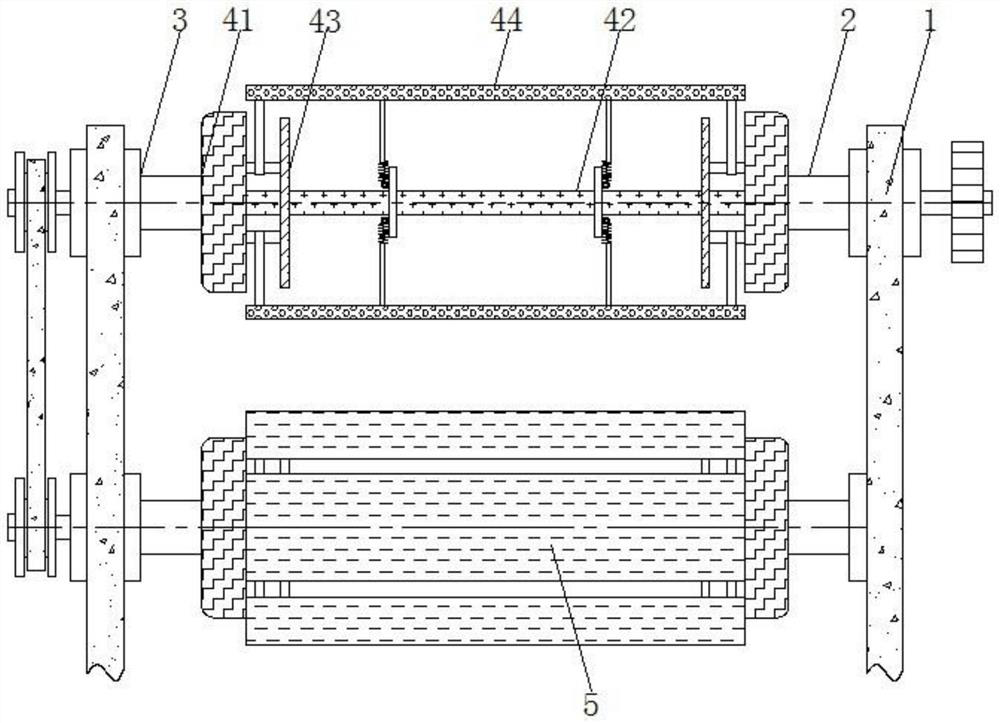

[0027] see Figure 1-6 , a copper foil laminating device with high flatness to avoid wrinkles, including a frame 1, a support 2 is arranged inside the frame 1, which is used for the support of the tension roller one 3 and the tension roller two 5. The surface of the support 2 Tension roller one 3 is provided. Tension roller one 3 and tension roller two 5 have the same structure and are distributed in parallel. Tension roller one 3 and tension roller two 5 are not on the same horizontal plane. The tension adjustment includes an adjustment mechanism 4 , which is located inside the tension roller 1 3 and the tension roller 2 5 , and is used to adjust the effective diameter of the circumference of the tension roller 1 3 and the tension roller 2 5 .

[0028] The inside of the adjustment mechanism 4 is provided with a fixed shaft seat 41 , which is fixedly connected with the support 2 , and the surface of the fixed shaft seat 41 away from the support 2 is provided with a uniform lin...

Embodiment 2

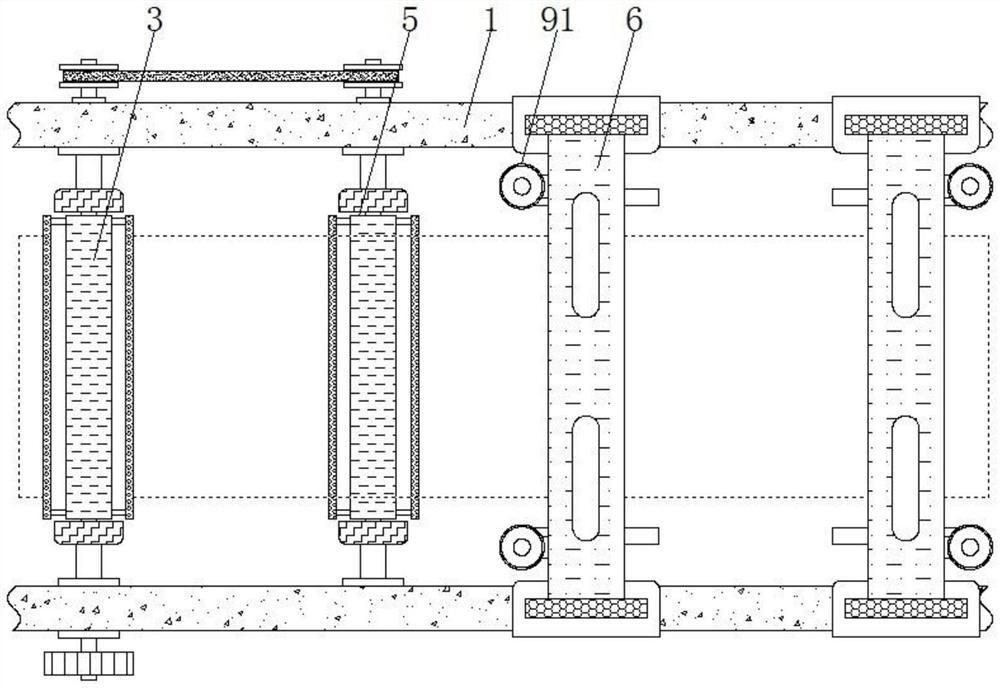

[0032] see Figure 1-6 , a copper foil laminating device with high flatness to avoid wrinkles, including a frame 1, a support 2 is arranged inside the frame 1, which is used for the support of the tension roller one 3 and the tension roller two 5. The surface of the support 2 Tension roller one 3 is provided. Tension roller one 3 and tension roller two 5 have the same structure and are distributed in parallel. Tension roller one 3 and tension roller two 5 are not on the same horizontal plane. The tension adjustment, including the adjustment mechanism 4, is used to adjust the effective diameter of the circumference of the tension roller one 3 and the tension roller two 5. The surface of the support 2 is provided with a tension roller two 5, which cooperates with the tension roller one 3 and is used for copper Adjustment of foil surface tension.

[0033] The surface of the frame 1 is fixedly connected with a support plate 6, and the inside of the support plate 6 is provided wit...

Embodiment 3

[0036] see Figure 1-6 , a copper foil laminating device with high flatness to avoid wrinkles, including a frame 1, a support 2 is arranged inside the frame 1, which is used for the support of the tension roller one 3 and the tension roller two 5. The surface of the support 2 Tension roller one 3 is provided. Tension roller one 3 and tension roller two 5 have the same structure and are distributed in parallel. Tension roller one 3 and tension roller two 5 are not on the same horizontal plane. The tension adjustment includes an adjustment mechanism 4 , which is located inside the tension roller 1 3 and the tension roller 2 5 , and is used to adjust the effective diameter of the circumference of the tension roller 1 3 and the tension roller 2 5 .

[0037] The inside of the adjustment mechanism 4 is provided with a fixed shaft seat 41 , which is fixedly connected with the support 2 , and the surface of the fixed shaft seat 41 away from the support 2 is provided with a uniform linea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap