UV die-cutting machine and die-cutting method adopting same

A die-cutting machine and die-cutting technology, applied in the direction of metal processing, etc., can solve the problems of low cutting efficiency, poor operation flexibility, energy consumption, etc., and achieve the effect of improving die-cutting efficiency, improving work efficiency, and fast replacement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

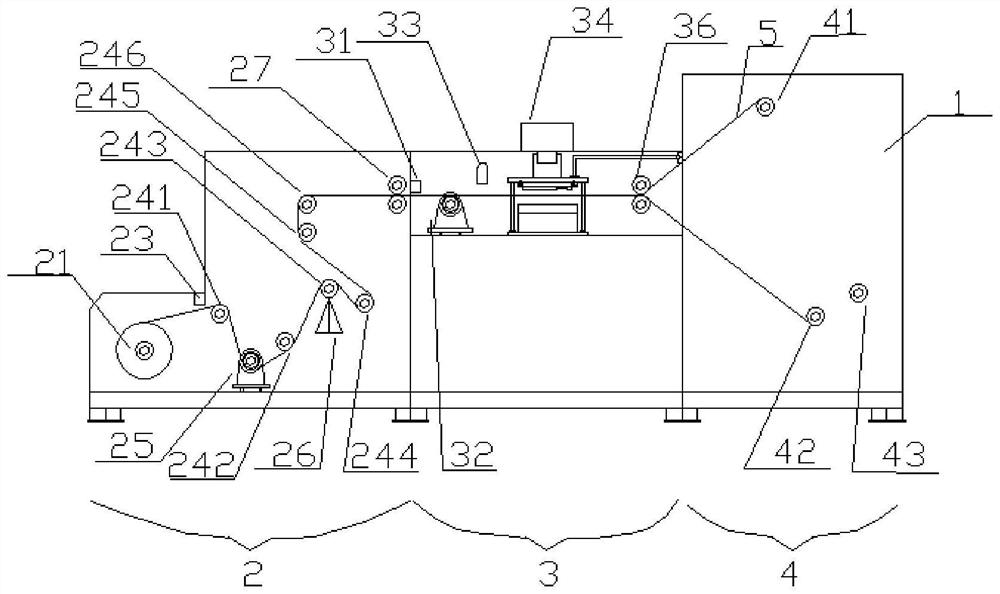

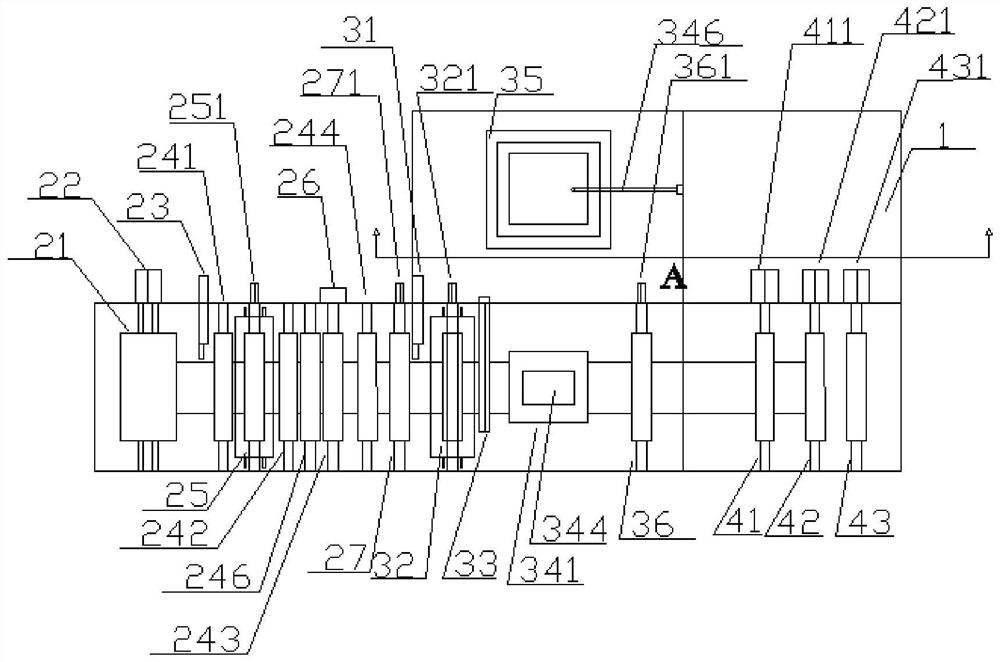

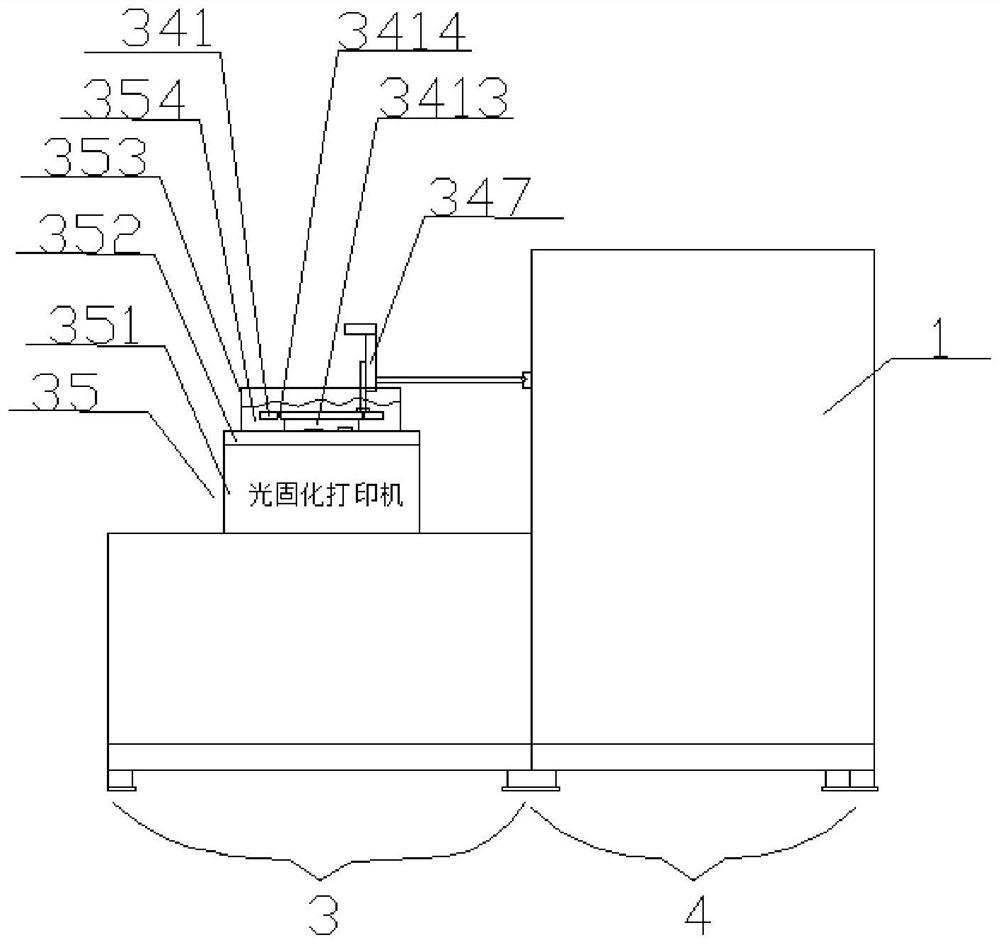

[0028] see Figure 1-4, the present invention provides the following technical solutions: a UV die-cutting machine and a die-cutting method using the equipment, including a frame 1, a side of the inner wall of the frame 1 is provided with a discharge mechanism 2, and the discharge mechanism 2 includes a rotary connection on the machine The discharge roller 21 at the edge of the inner wall of the frame 1, one end of the discharge roller 21 is connected with a magnetic powder brake 22, and the inner wall of the frame 1 near the side of the discharge roller 21 is fixedly connected with a first edge detection sensor 23. The inner side wall of the frame 1 close to the side of the first edge detection sensor 23 is rotatably connected with the first feeding roller 241, and the outer surface of the frame 1 close to the side of the first feeding roller 241 is fixedly connected with the first deviation correcting roller stepping Motor 251, the output end of the first deviation-correctin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com