Servo-motor-driven forward and reverse wrapping mechanism of agricultural radial tire building machine

A radial tire and servo motor technology, applied in the field of radial tire building, can solve problems such as affecting the quality of tire production, affecting the efficiency of tooling replacement, etc., to avoid unstable factors, improve replacement efficiency, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

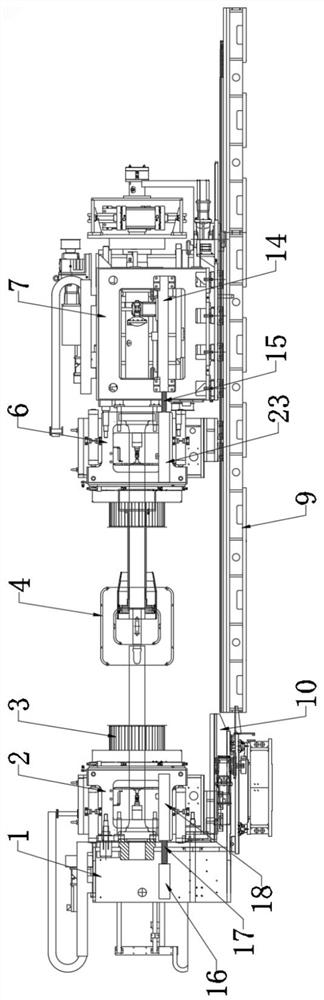

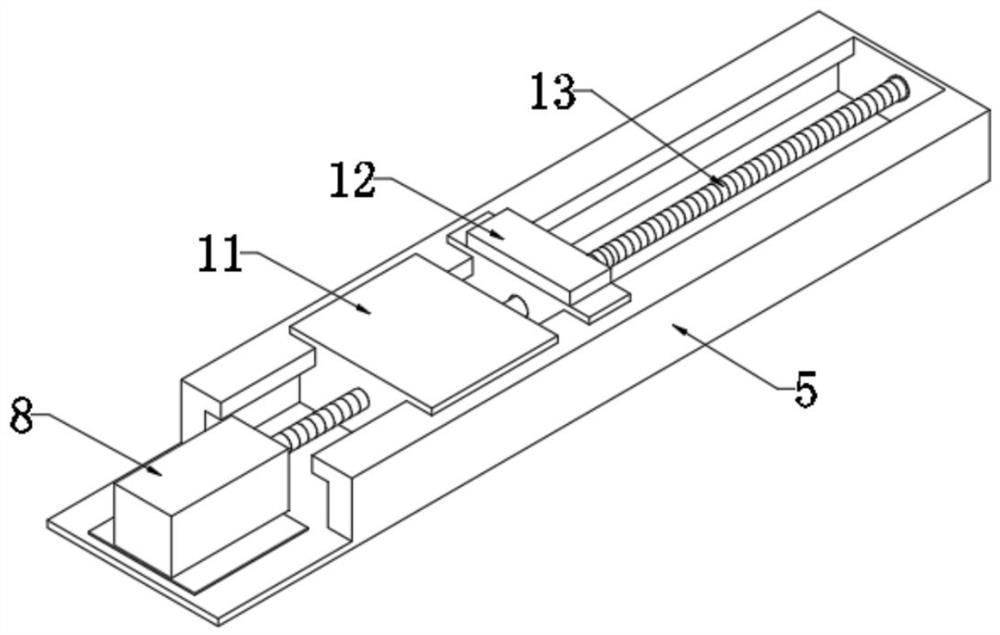

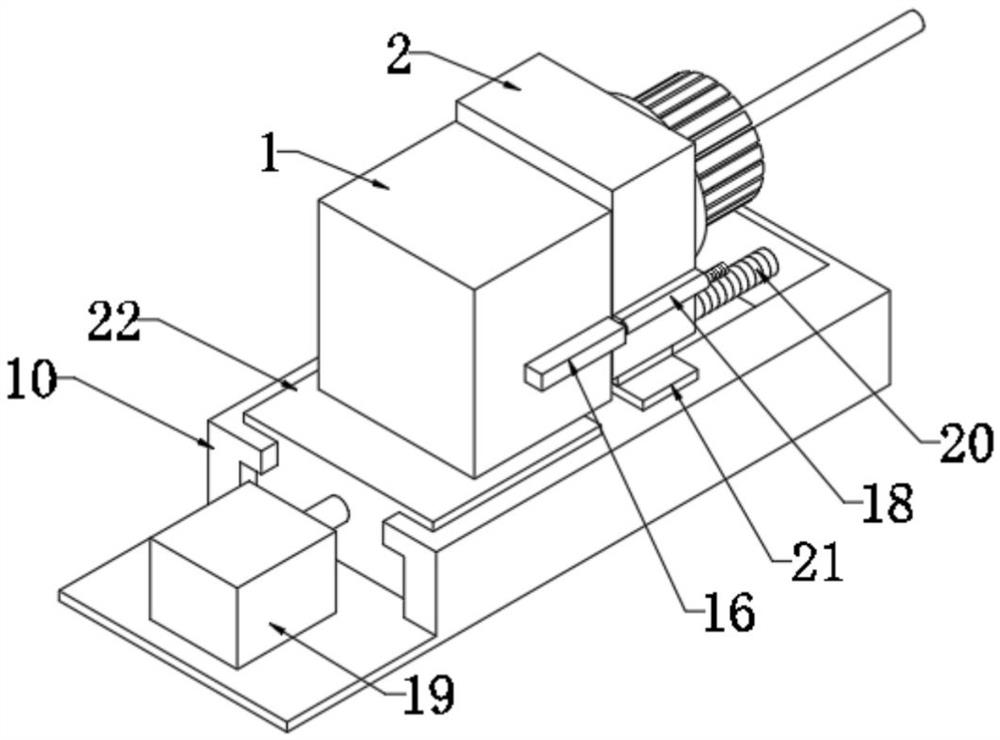

[0029] Such as Figure 1-Figure 3 As shown, a servo motor-driven agricultural radial tire building machine provided by the present invention includes a base 9 and a tail case guide rail 10, the tail case guide rail 10 is fixedly connected to one end of the base 9, and the tail case guide rail 10 slides A tail chassis 1 is provided, and a main chassis 7 is slidably arranged on the base 9. The side of the main chassis 7 close to the tail chassis 1 is connected with a first positive and negative wrapping device 6 through a first driving mechanism, and the first driving mechanism includes a servo motor 14 , the servomotor-14 is fixedly installed on the side of the main frame 7, the side of the first front and back packaging device 6 is fixedly connected with an internal thread pipe-23, and the end of the rotating shaft of the servomotor-14 is fixedly connected with a screw mandrel-15, the screw mandrel One end of one 15 is threadedly connected with the internally threaded pipe one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com