Layering device for paper packaging

A layering device and packaging technology, applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems of not being able to ensure the accuracy of the placement position, the quantity and consistency of handkerchief paper, etc., and achieve the effect of convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

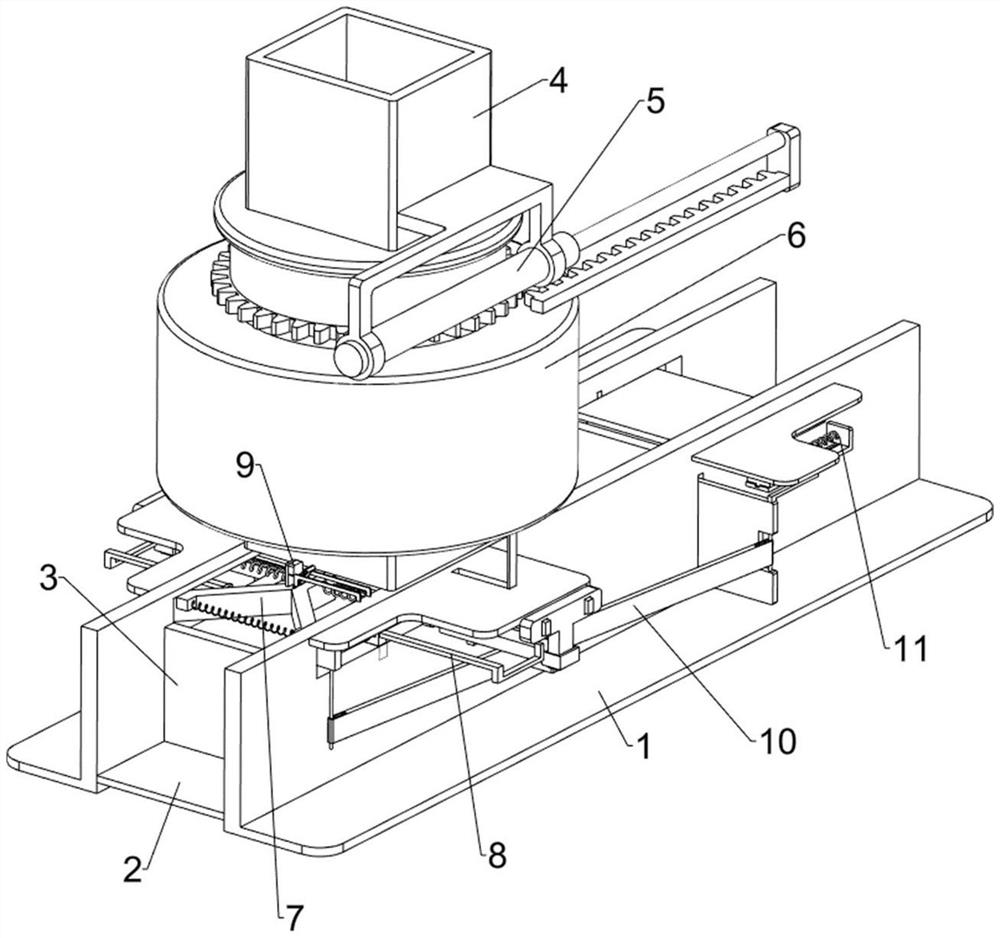

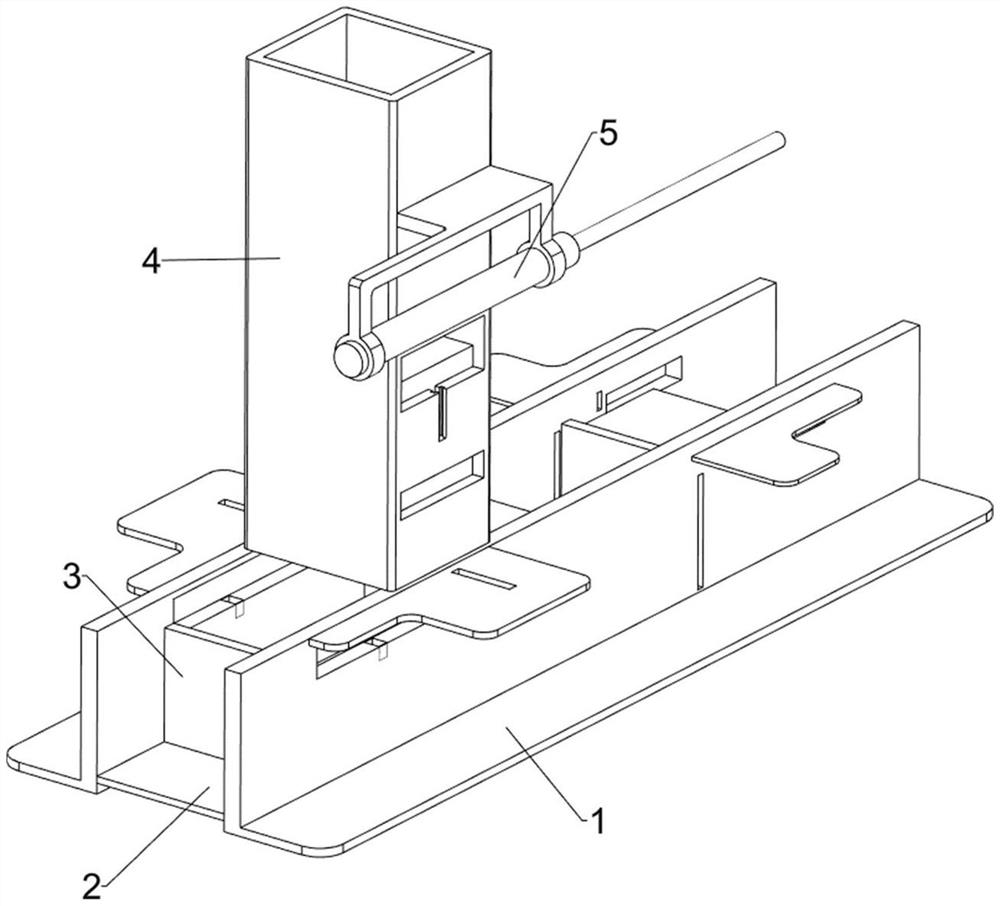

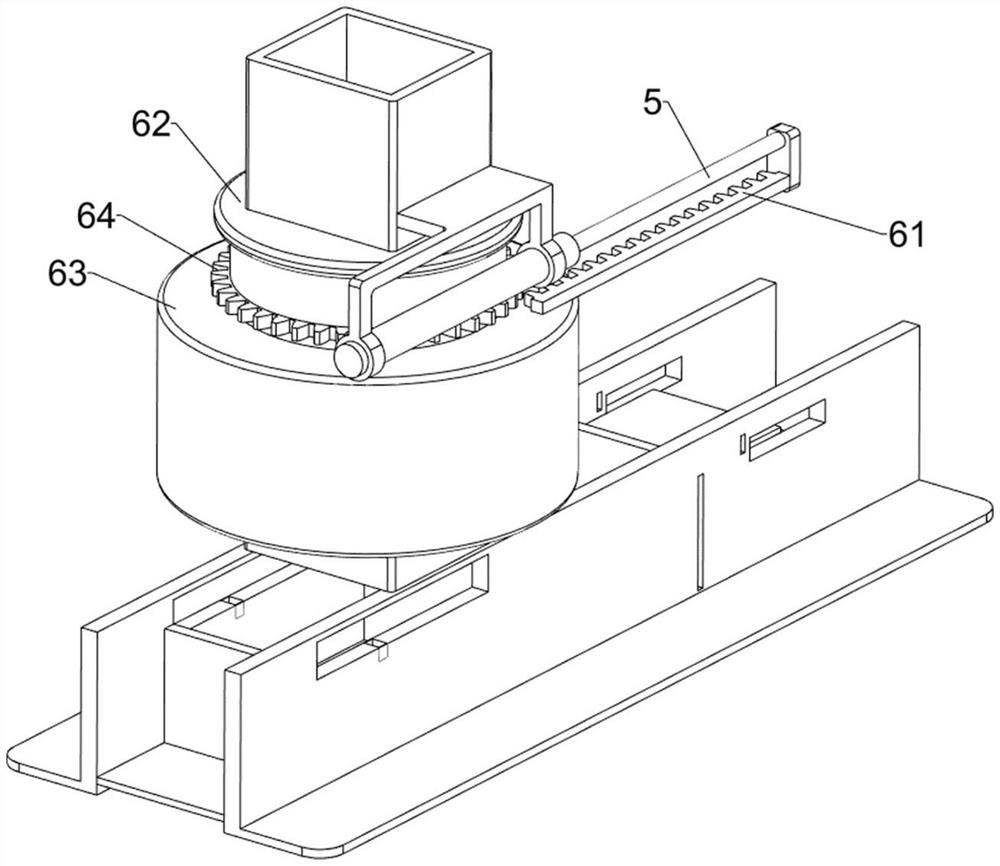

[0043] A layering device for paper packaging, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it includes a side frame 1, a conveying mechanism 2, a baffle plate 3, a paper placement frame 4, an electric push rod 5, a paper layering mechanism 6, a bottom opening and closing mechanism 7, and a quick opening and closing mechanism 8. Other supporting devices are equipped with There are two side frames 1, and the side frames 1 are arranged symmetrically. The conveying mechanism 2 is arranged on other devices. The quantity is at least three, and the top of the side frame 1 is jointly fixed with a paper placing frame 4, and stacked handkerchiefs are placed in the paper placing frame 4, and an electric push rod 5 is fixed on the right side of the upper part of the paper placing frame 4, and the paper is placed The frame 4 is provided with a paper layering mechanism 6 and is connected wit...

Embodiment 2

[0053] On the basis of Example 1, such as Figure 11 and Figure 12As shown, a rate control mechanism 9 is also included. The rate control mechanism 9 is arranged on the side frame 1 on the right and is connected with the second wedge strip 76. The rate control mechanism 9 is convenient for the device to control the opening according to the conveying speed of the conveying mechanism 2 Plywood 74 is opened blanking, and speed control mechanism 9 includes touch sensor 91, first fixed mount 92, turret 93 and torsion spring 94, and the second wedge bar 76 top that is positioned at left side is fixedly installed with touch sensor 91, is positioned at Two first fixed mounts 92 are affixed to the top of the side frame 1 on the right, and a turret 93 is connected to the first fixed mount 92 in a common rotation manner. The second wedge-shaped bar 76 on the right is in contact, and the second wedge-shaped bar 76 on the right can prop up the turret 93, and a torsion spring 94 is connec...

Embodiment 3

[0056] On the basis of Example 2, such as Figure 13 As shown, a paper stop mechanism 10 is also included. The paper stop mechanism 10 is arranged on the side frame 1 and connected with the second wedge-shaped strip 76. The paper stop mechanism 10 is used to ensure that the gap between the layered handkerchief papers in the conveying process is The distance between them is equal, the paper stop mechanism 10 includes a fixed rod 101, a second fixed frame 102, a sliding plate 103 and a rotating plate 104, the bottom of the second wedge bar 76 is fixedly welded with a fixed rod 101, and the fixed rod 101 is located on the outside of the side frame 1, The outside of the side frame 1 is fixedly connected with a second fixed frame 102, and the rear part of the side frame 1 is slidably connected with a sliding plate 103. The sliding plate 103 can block a part of the handkerchief paper which is divided into layers, and the second fixed frame 102 is rotated. Connected with a rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com