Water-based low-permeability single-component acrylate emulsion and preparation method thereof

An acrylic, low water permeability technology, applied in the direction of coating, etc., can solve the problems of easy cracking and high water permeability, and achieve the effects of low water absorption, good water resistance, and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

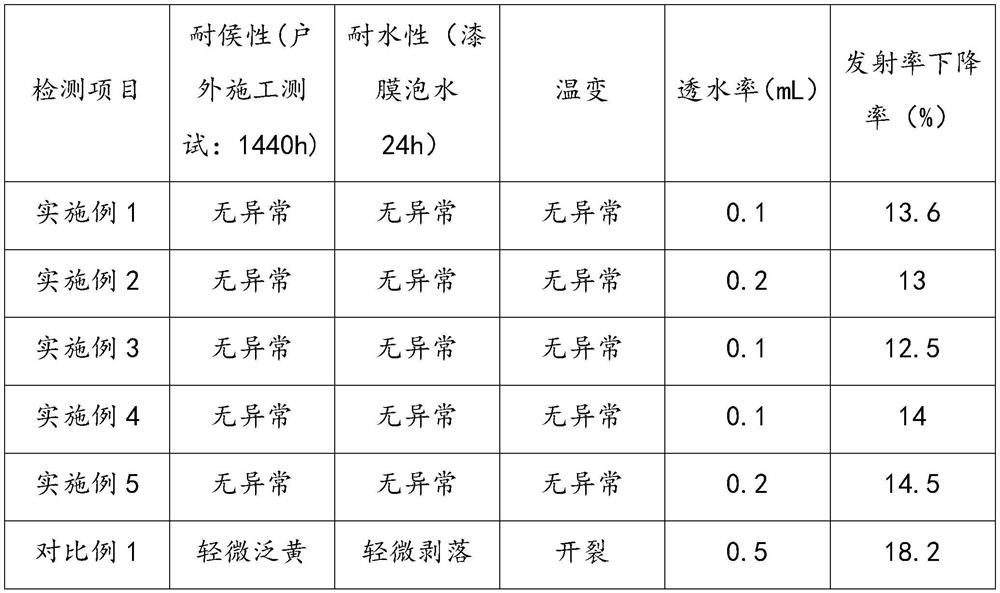

Examples

Embodiment 1

[0032] A water-based low water permeability one-component acrylic ester emulsion, used for architectural interior and exterior wall paint finish paint varnish, including the following raw materials: methyl methacrylate 15kg, tert-butyl methacrylate 8kg, methacrylic acid 0.4kg, acrylic acid 0.3kg, vinyl tertiary carbonate (VV-10) 2kg, butyl acrylate 12kg, glycidyl methacrylate 0.5kg, vinyltrimethoxysilane 0.2kg, SR-10 reactive emulsifier 0.8kg, dodecane Sodium diphenyl ether disulfonate 1.94kg, alkyl polyoxyethylene ether 1kg, OE-3002kg, ammonium persulfate 0.2kg, tert-butyl hydroperoxide 0.15kg, L-ascorbic acid 0.1kg, polymerization inhibitor (ZJ- 701) 0.001kg, ammoniacal liquor 0.5kg, water 60kg, comprise following preparation steps:

[0033] (1) Pre-emulsification

[0034] a) Under normal temperature and pressure, 60% of the total mass of two non-reactive emulsifiers, sodium dodecyl diphenyl ether disulfonate and alkyl polyoxyethylene ether, and 55% of the total mass of dei...

Embodiment 2

[0046] A water-based low water permeability self-cleaning finish varnish with one-component acrylate emulsion, used for architectural interior and exterior wall paint finish varnish, including the following raw material components: methyl methacrylate 15kg, tert-butyl methacrylate 8kg , methacrylic acid 0.4kg, acrylic acid 0.4kg, tertiary vinyl carbonate (VV-10) 3kg, butyl acrylate 11kg, glycidyl methacrylate 0.4kg, vinyltrimethoxysilane 0.2kg, SR-10 reactive type Emulsifier 0.5kg, sodium dodecyl diphenyl ether disulfonate 2kg, alkyl polyoxyethylene ether 1kg, OE-30022kg, ammonium persulfate 0.15kg, tert-butyl hydroperoxide 0.12kg, L-ascorbic acid 0.1kg , polymerization inhibitor (ZJ-701) 0.005kg, sodium hydroxide 0.8kg, water 60kg, comprise following preparation steps:

[0047] (1) Pre-emulsification

[0048] a) Under normal temperature and pressure, 50% of the total mass of two non-reactive emulsifiers, sodium dodecyl diphenyl ether disulfonate and alkyl polyoxyethylene eth...

Embodiment 3

[0060] One-component acrylate emulsion for water-based low water permeability self-cleaning finish varnish, used for building interior and exterior wall paint finish varnish, including the following raw material components: methyl methacrylate 11kg, tert-butyl methacrylate 12kg , Methacrylic acid 0.6kg, acrylic acid 0.3kg, vinyl tertiary carbonate (VV-10) 3kg, butyl acrylate 11kg, vinyltrimethoxysilane 0.7kg, SR-10 reactive emulsifier 0.4kg, dodecyl Sodium diphenyl ether disulfonate 1.5kg, alkyl polyoxyethylene ether 1kg, OE-300 2.5kg, sodium persulfate 0.25kg, tert-butyl hydroperoxide 0.15kg, L-ascorbic acid 0.11kg, polymerization inhibitor (ZJ- 701) 0.001kg, potassium hydroxide 0.5kg, water 56.62kg, comprising the following preparation steps:

[0061] (1) Pre-emulsification

[0062] a) Under normal temperature and pressure, 50% of the total mass of two non-reactive emulsifiers, sodium dodecyl diphenyl ether disulfonate and alkyl polyoxyethylene ether, and 40% of the total m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com