Waste heat recovery detection device for biomass combustion

A technology of waste heat recovery and detection device, applied in the direction of measurement device, temperature measurement of moving fluid, measurement of heat, etc., can solve the problems of high heat and heat waste in boiler supply pipeline, prevent energy waste, ensure accuracy, and improve sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

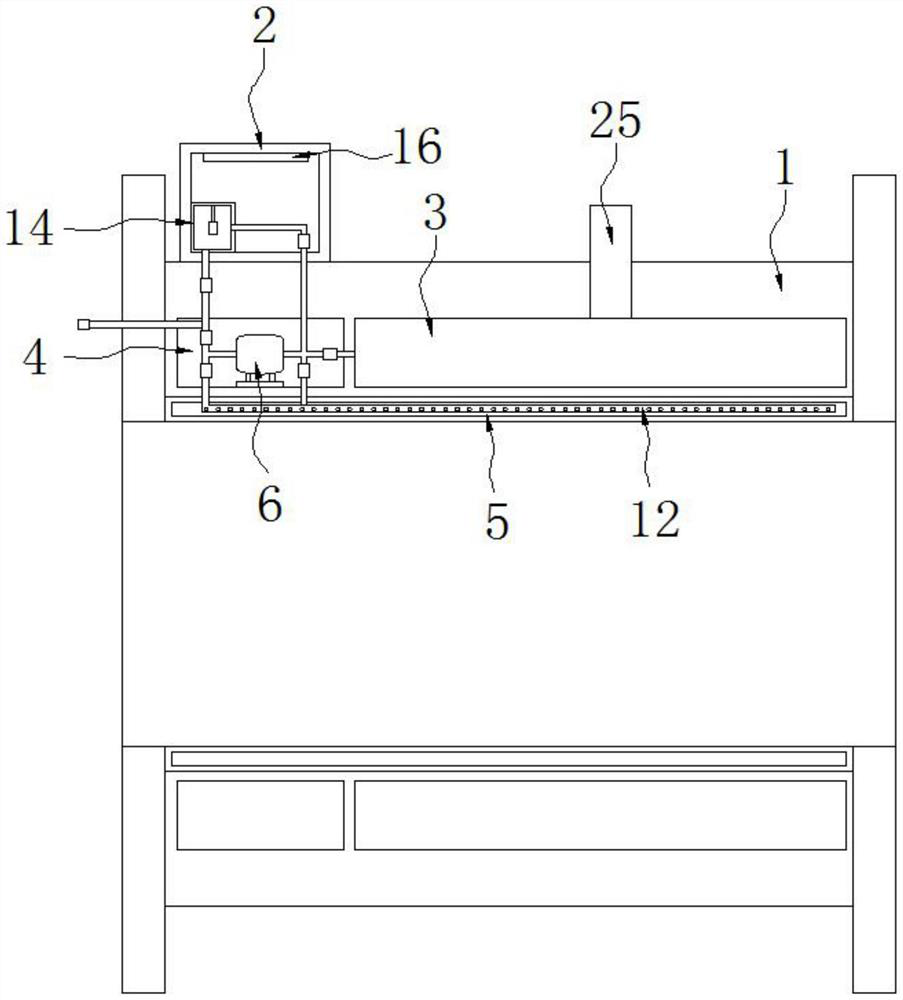

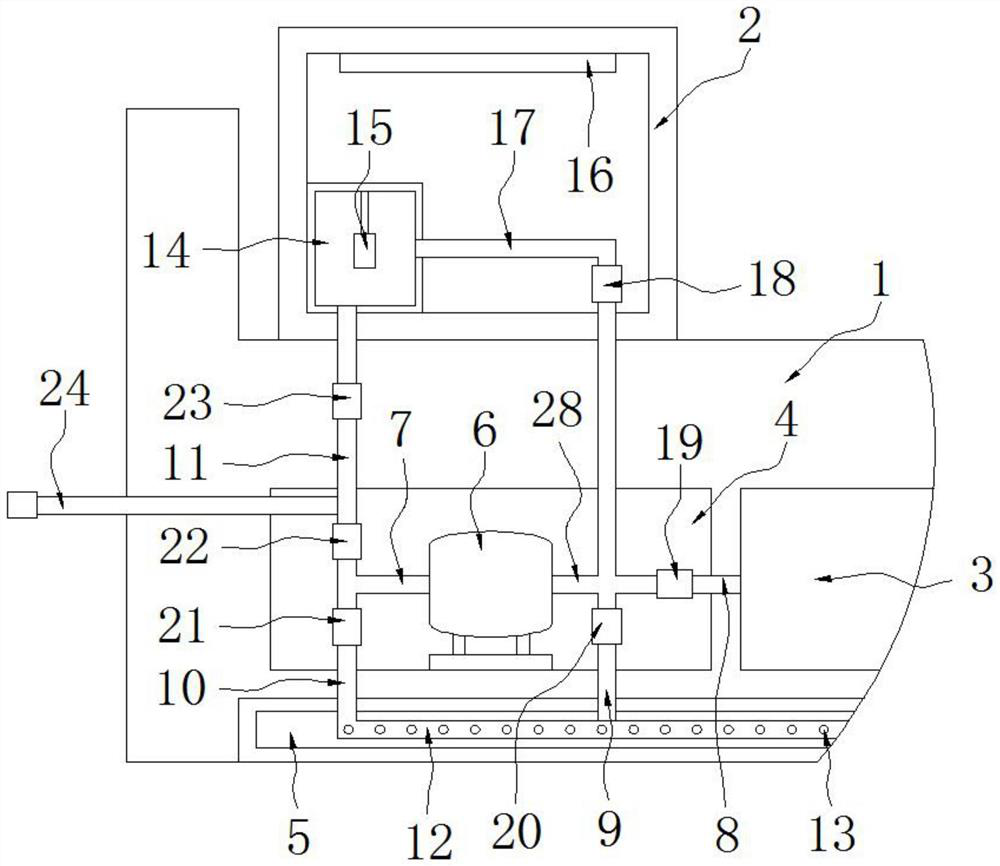

[0024] As a preferred embodiment of the present invention, a processor 16 is fixedly installed in the detection box 2, and a power line 27 is connected to the rear side of the detection box 2, and the power line 27 is connected to the processor 16 and the temperature sensor respectively. 15. The water pump 6, the return valve 18, the water supply valve 19, the circulation valve 20, the connection valve 21, the discharge valve 22 and the detection valve 23 are electrically connected, and the processor 16 is respectively connected to the temperature sensor 15, the water pump 6, the return valve 18, The water supply valve 19, the circulation valve 20, the connection valve 21, the discharge valve 22 and the detection valve 23 are electrically connected.

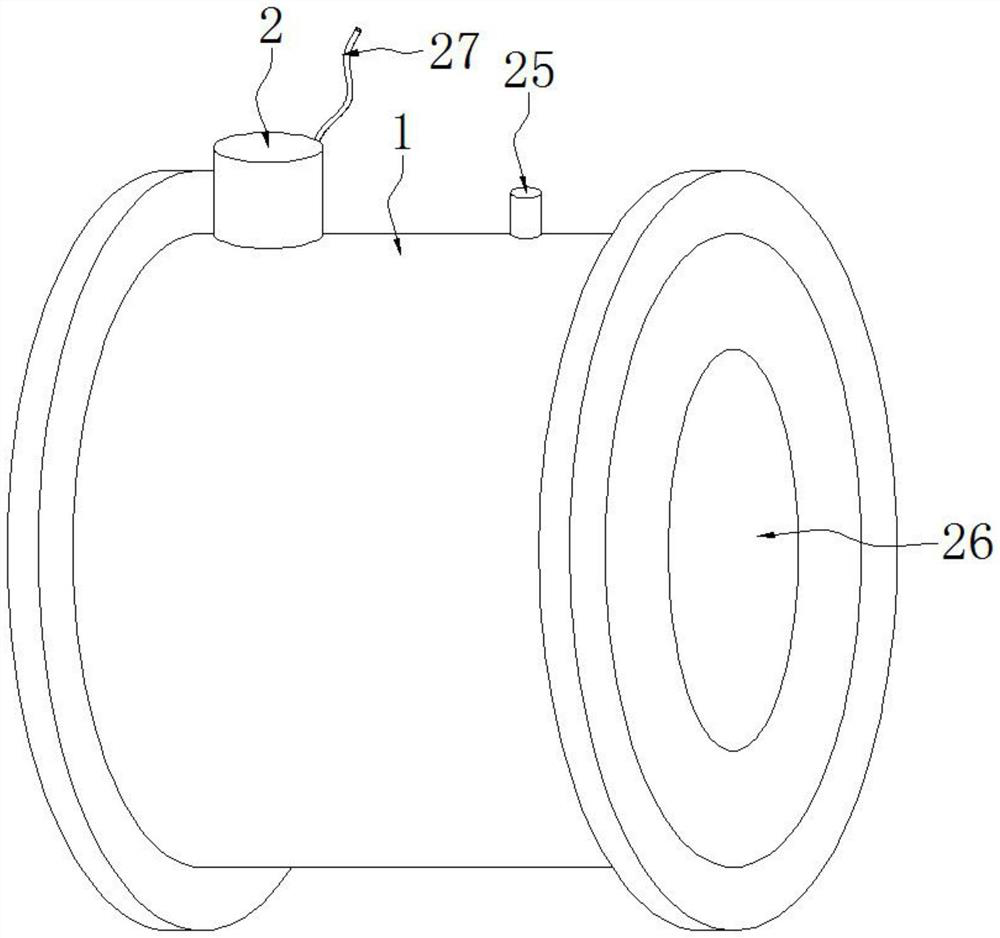

[0025] As a preferred embodiment of the present invention, when in use, the collection seat 1 is sleeved on the boiler output pipe through the central hole 26, the power line 27 is connected to the boiler control system, the addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com