Automatic work fixture special for unmanned X-ray detection of helicopter rotor

A helicopter rotor and automatic engineering technology, applied in the field of tooling fixtures, can solve the problem that the fixtures block the wings and cannot realize complete detection, and achieve the effect of simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

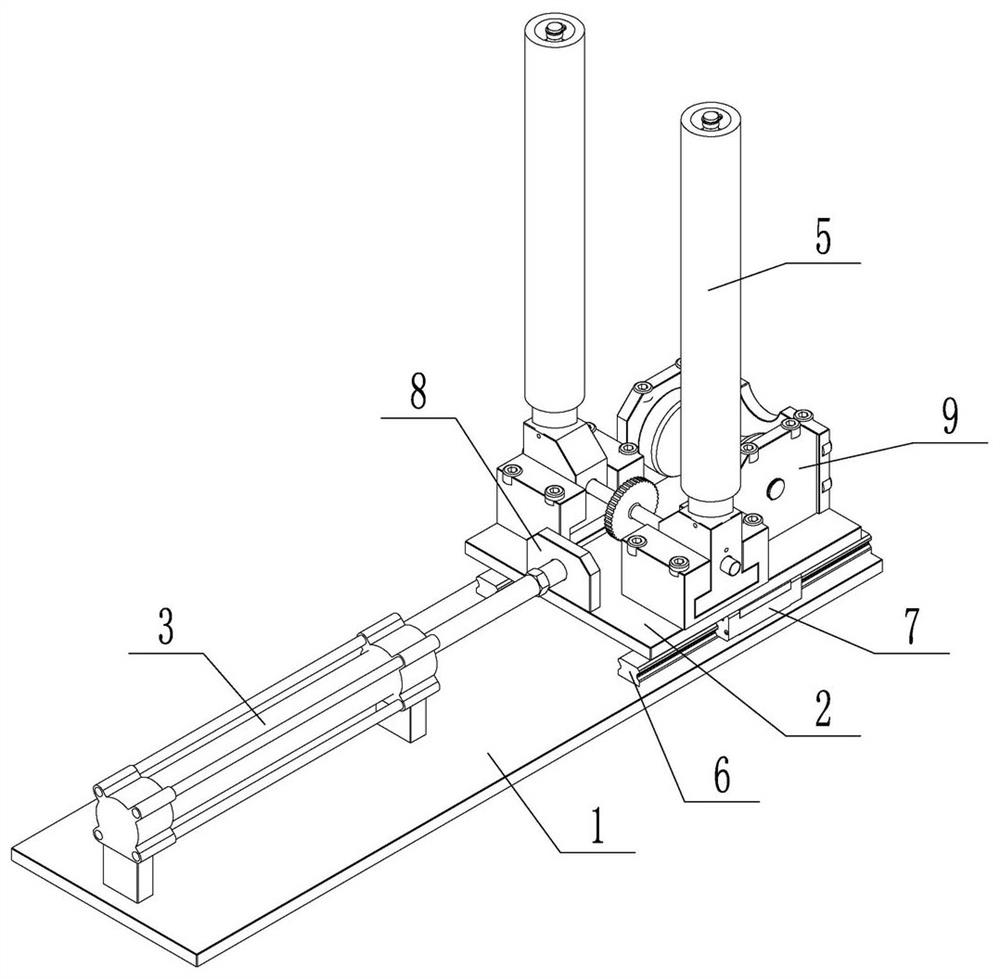

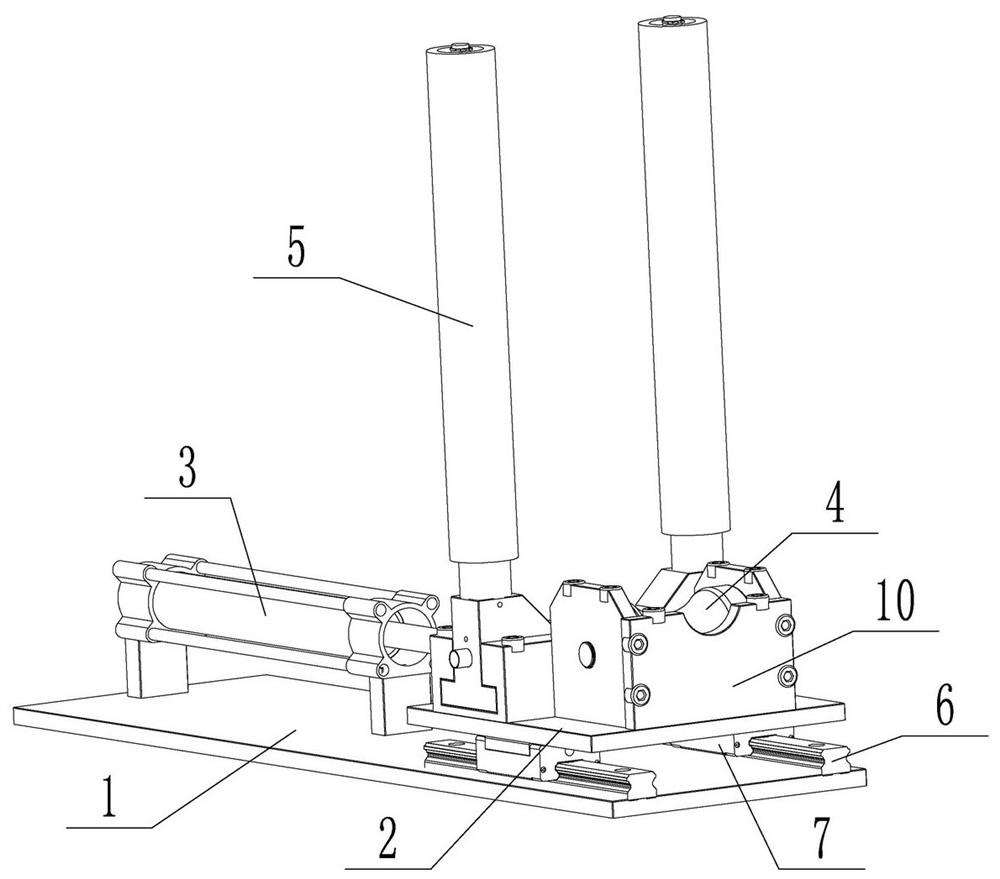

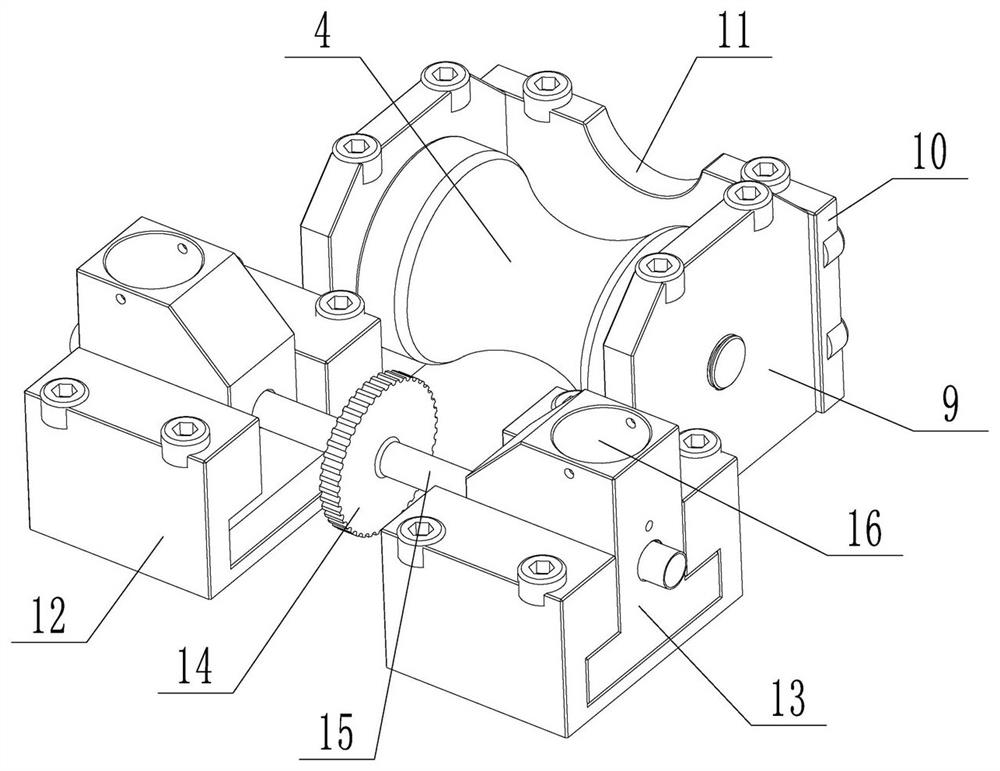

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Depend on Figure 1 to Figure 6 It can be seen that the special automatic tooling fixture for unattended X-ray detection of the helicopter rotor includes a base 1, a sliding base 2 is slidably installed on one side above the base 1, and a cylinder 3 connected to the sliding base 2 is fixed on the other side above the base 1. 2. A U-shaped roller 4 is fixed on the side away from the cylinder 3. The axis of the U-shaped roller 4 is perpendicular to the axis of the cylinder 3. The side of the sliding base 2 close to the cylinder 3 is provided with a clamping roller group. The clamping roller group includes two clamping rollers 5. The connecting line of two nip rollers 5 is parallel to the axis of U-shaped roller 4 .

[0021] When the present invention is in use,

[0022] Adjust the distance between the two pinch ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com