Point inspection method based on industrial equipment

A technology of industrial equipment and point inspection, applied in data processing applications, instruments, calculations, etc., can solve problems such as irregular point inspection operations, untimely point inspections, and untraceable faults, etc., to achieve refined point inspections management, improving inspection efficiency, and reducing accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings.

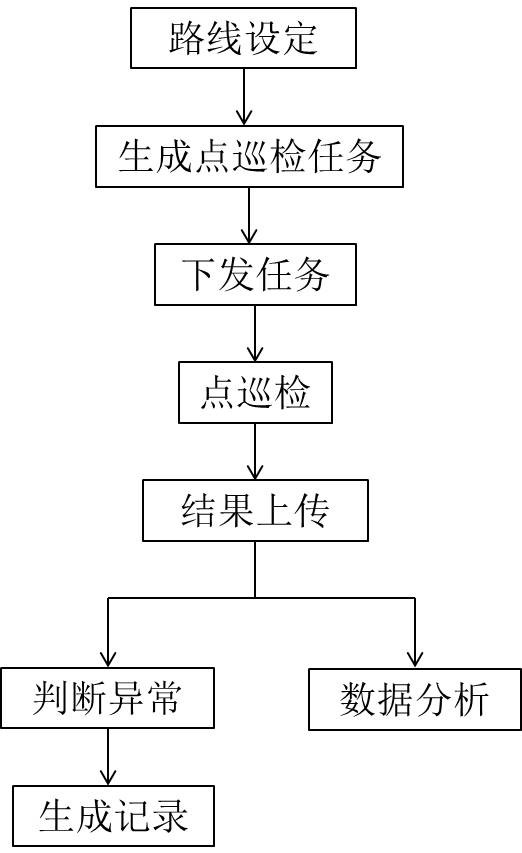

[0017] Such as figure 1 It is a flow chart of the point inspection method based on industrial equipment in the present invention, and the point inspection method specifically includes the following steps:

[0018] (1) Provide the inspection standards for industrial equipment points, including: inspection methods, inspection standards, inspection parameters and standards, abnormal levels, etc., and automatically update the inspection standards for industrial equipment points; statistically participate in point inspections Industrial equipment, set point inspection routes, and generate point inspection tasks;

[0019] (2) Send the generated point inspection tasks to the point inspection personnel, and the point inspection personnel will perform point inspections according to the generated point inspection tasks, and upload the results of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com