Three-phase common-box insulator assembly and GIS

A technology of three-phase common box and insulators, which is applied in the direction of electrical components, switchgear settings, switchgear, etc., can solve the problems of high design and processing costs, and achieve the effects of improving service life, suppressing partial discharge, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

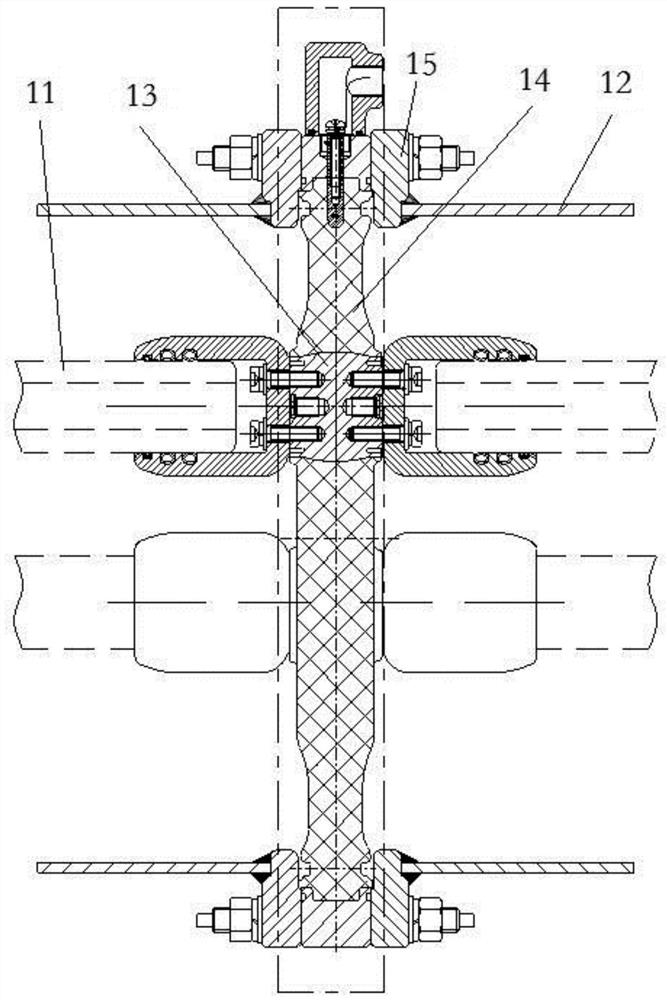

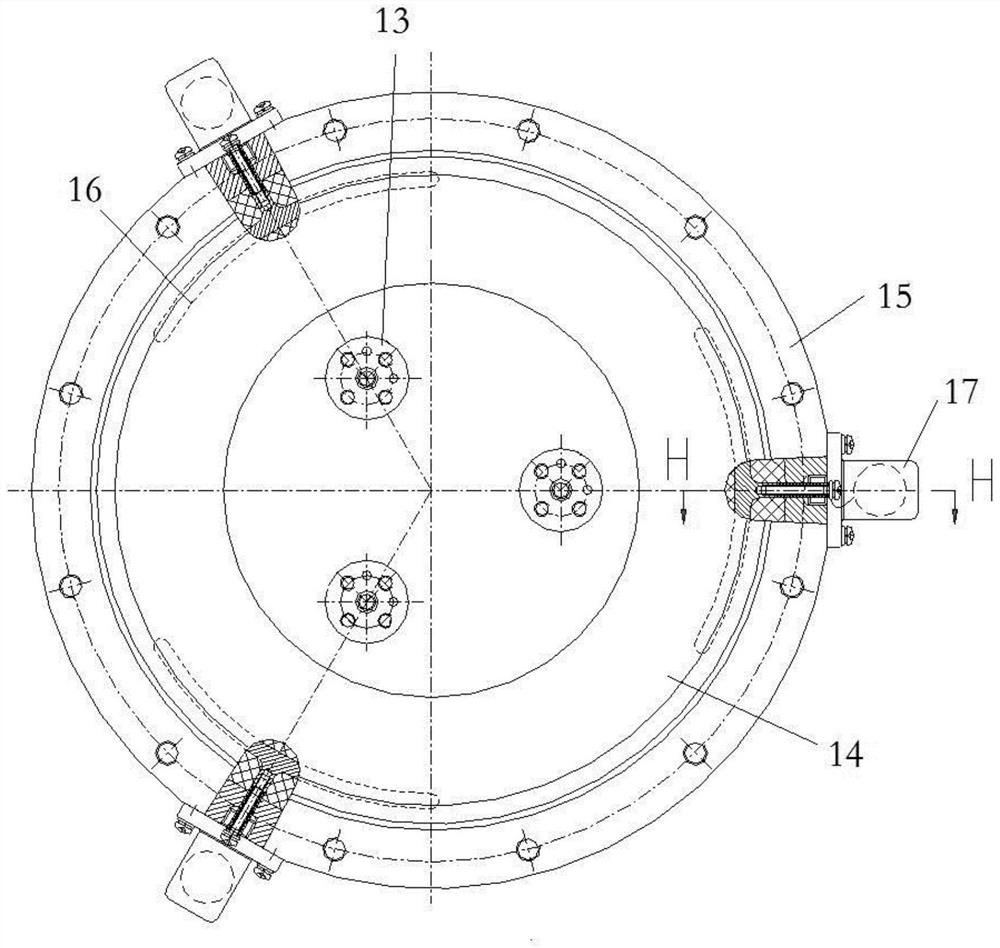

[0060] like figure 1 and figure 2 As shown, the GIS includes a shell 12 and a three-phase common box insulator assembly. A three-phase central conductor 11 is arranged inside the shell 12. The three-phase common box insulator assembly includes a three-phase common box insulator, and the three-phase common box insulator is a disc insulator. The three-phase common box insulator includes a three-phase central insert 13 arranged in the shape of "pin", a flange 15, and an insulating part 14 arranged between the central insert 13 and the flange 15. The three-phase central conductor 11 is connected to the three-phase The central inserts 13 are connected one by one, and the housing 12 is connected with the flange 15 . Corresponding to each central insert 13 in the insulating part 14 is cast with an electrode 16 , and the electrode 16 is arranged correspondingly to the corresponding central insert 13 along the radial direction.

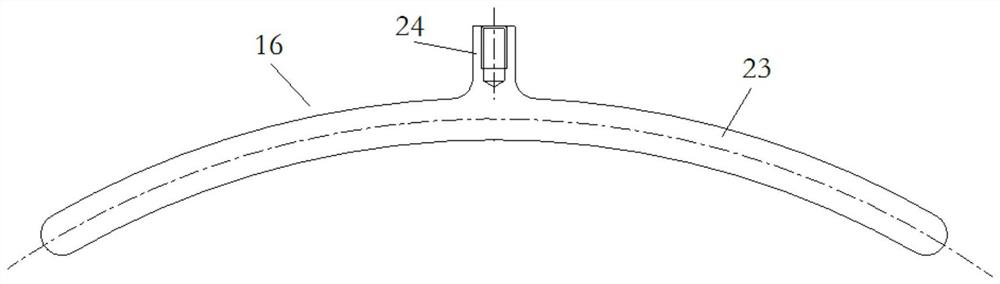

[0061] In this example, if Figure 2 to Figure 4 As ...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that: in Embodiment 1, a threaded hole is provided on the connecting portion 24, and the charging display wiring body includes a connecting bolt 19 matched with the threaded hole, and the connecting bolt 19 is provided with a connection bolt 19 for connecting with the charging display device. Connected leads 22. In this embodiment, a light hole is provided on the connection part, and the charged display wiring body includes a polished rod, which passes through the radial through hole on the flange to cooperate with the light hole of the connection part, and the end of the polished rod far away from the central insert is provided with a Lead wires connected to live display devices. In other embodiments, the threaded hole on the connecting part is canceled, and when it is necessary to monitor the live display condition, the insulating seat is fixed on the outer peripheral surface of the flange, and a metal insert ...

Embodiment 3

[0074] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the joint 17 has a threading channel 18 for the lead wire 22 to pass through, and the threading channel 18 includes a threading entrance for the lead wire 22 to pass through and a threading exit for the lead wire 22 to pass through. , the threading entrance communicates with the radial through hole of the flange 15, and the threading channel 18 is an L-shaped channel. In this embodiment, the joint has a "one"-shaped threading channel, and the threading channel's threading entrance and threading exit are located on the same straight line. In other embodiments, the joints are omitted, and in order to prevent the wiring bolts from being exposed, insulating resin may be poured on the wiring bolts for protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com