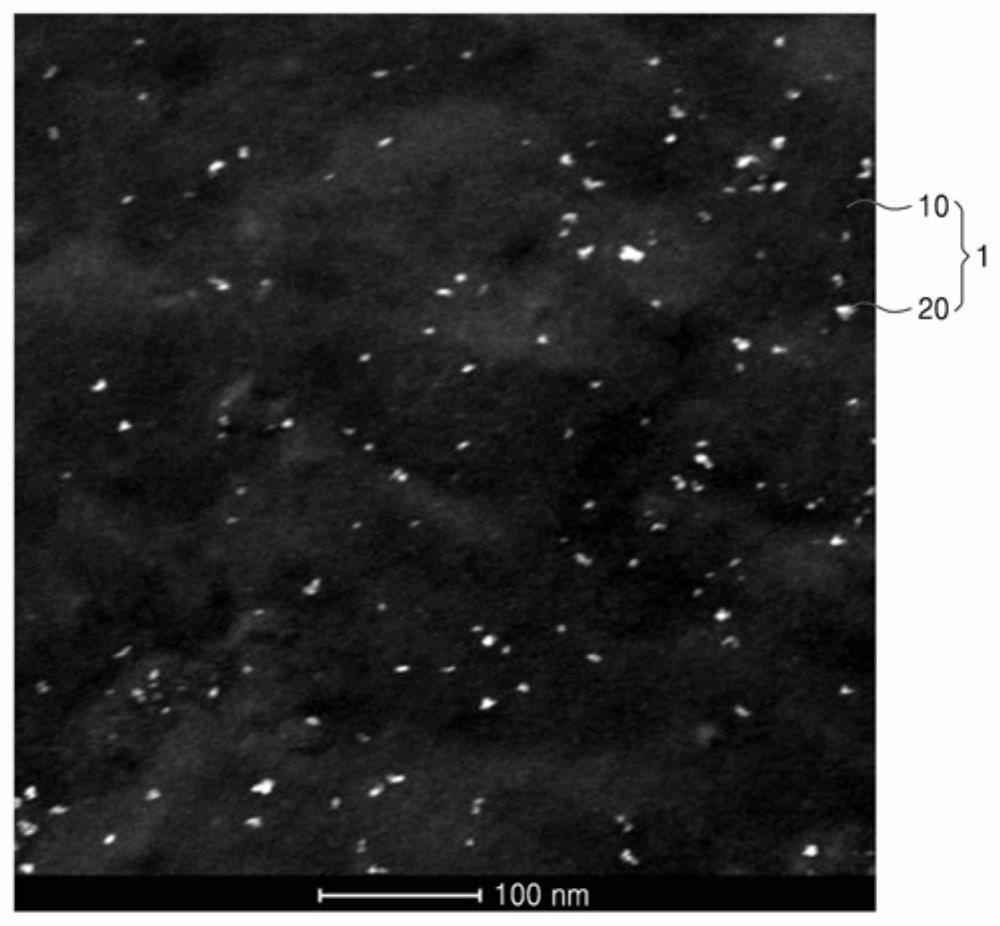

Material for hot stamping and method for producing same

A hot stamping and reheating technology, which is applied in the manufacture of tools, metal rolling, heat treatment furnaces, etc., can solve the problems of uncontrollable hydrogen delayed fracture and achieve excellent mechanical and physical properties and excellent hydrogen-induced delayed fracture characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

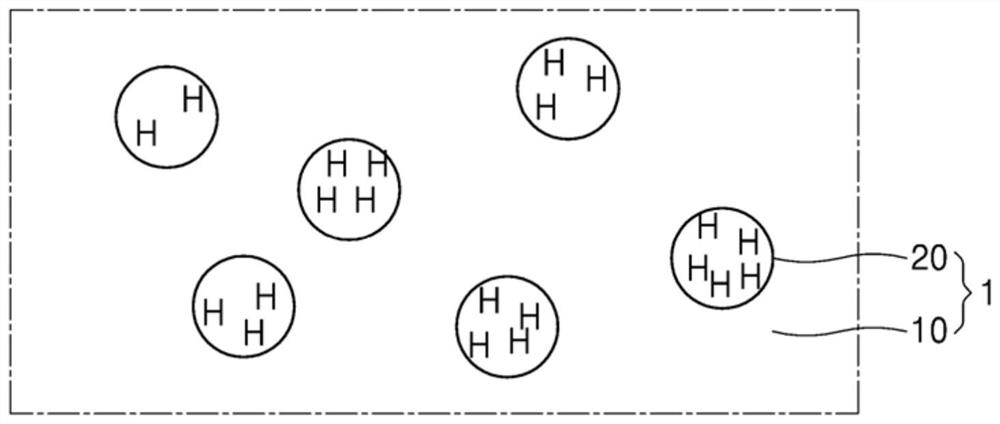

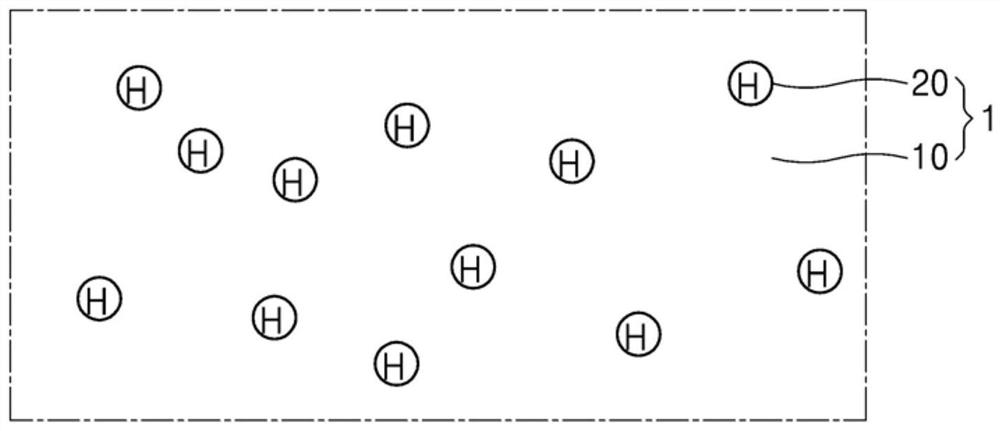

[0028] As the invention allows for various changes and has many embodiments, specific embodiments will be shown in the drawings and described in detail. The effects and features of the present invention and methods for achieving the effects and features will become more apparent with reference to the embodiments described in detail below and the accompanying drawings. However, the present invention is not limited to the embodiments disclosed below, but can be implemented in various forms.

[0029] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings, and when describing with reference to the accompanying drawings, the same reference numerals will be assigned to the same or corresponding technical features, and repeated descriptions thereof will be omitted.

[0030] In the following embodiments, the terms "first", "second", etc. are used to distinguish one component from other components, and do not have a lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com