Aqueous paint composition

A technology of water-based coatings and compositions, applied in the direction of polyurea/polyurethane coatings, coatings, latex paints, etc., to achieve excellent mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3 and comparative example 1 to 2

[0070] Embodiment 1 to 3 and comparative example 1 to 2: the making of aqueous coating composition

[0071] The components were sequentially mixed in the order shown in Table 1 below, and the final viscosity was set at 55 seconds in a No. 4 Ford cup to prepare water-based paint compositions of Examples and Comparative Examples.

[0072] 【Table 1】

[0073] Element

Example 1

Example 2

Example 3

Comparative example 1

Comparative example 2

11.29

11.29

11.29

11.29

11.29

Cosolvent 1

3.15

3.15

3.15

3.15

3.15

Dispersant

1.46

1.46

1.46

1.46

1.46

0.94

0.94

0.94

0.94

0.94

Lactone-modified water-soluble acrylic resin

13.12

13.12

13.12

-

13.12

-

-

-

13.12

-

TiO 2 pigment

13.84

13.84

13.84

13.84

13.84

Acrylic Latex Resin

36.61

36.61

36.61

...

experiment example

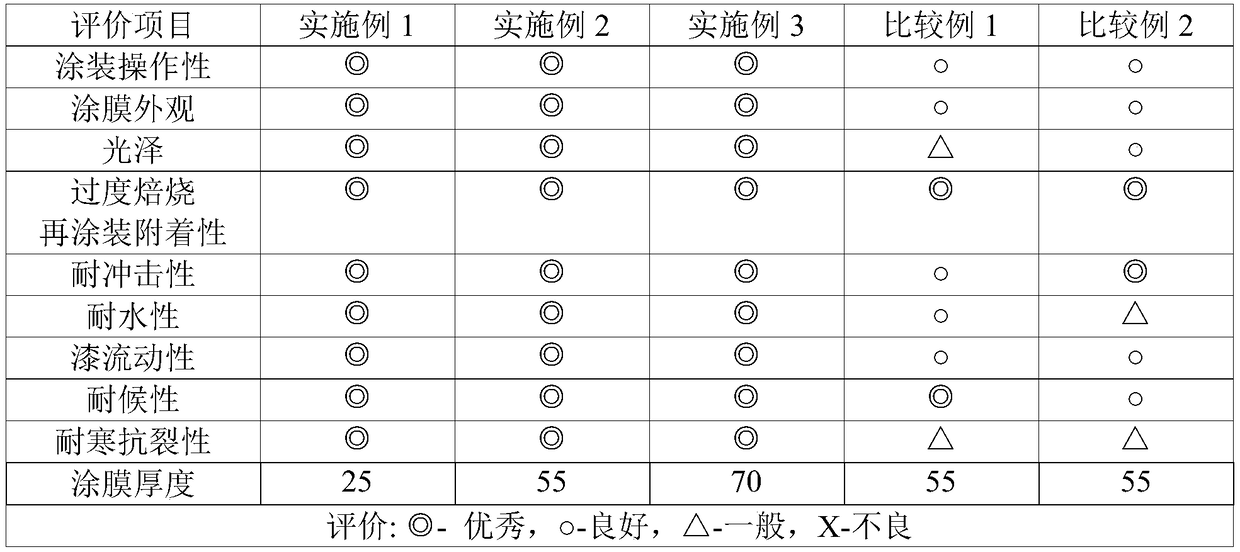

[0091] Experimental example: Appearance and physical property evaluation

[0092] On the surface of the electrophoretic surface coated on the substrate, the water-based coating composition of each example and comparative example was used as a primer (dried coating film thickness: 25 μm to 70 μm) for spin handle coating, and at 80 ° C, hot air was blown for 3 minutes to evaporate the remaining water in the paint. Then, it is cured at 140° C. to 150° C. for 20 to 30 minutes in a common drying oven to form a final coating film. The appearance and physical properties of the final coating film were measured and evaluated according to the following methods, and the results are shown in Table 2 below.

[0093] (1) Coating operability

[0094] According to the spraying state and the degree of wetting of the base material when the paint is sprayed, it is rated as excellent, good, fair, and poor.

[0095] (2) Appearance of coating film

[0096] The final CF value was measured using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com