Re-doped copper-tin alloy contact wire and preparation method thereof

A technology of copper-tin alloy and contact wire, which is applied in the direction of metal/alloy conductors, conductors, conductive materials, etc., can solve problems such as loss, achieve the goals of improving organizational structure, eliminating cast dendrite structure, and refining cast rod grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

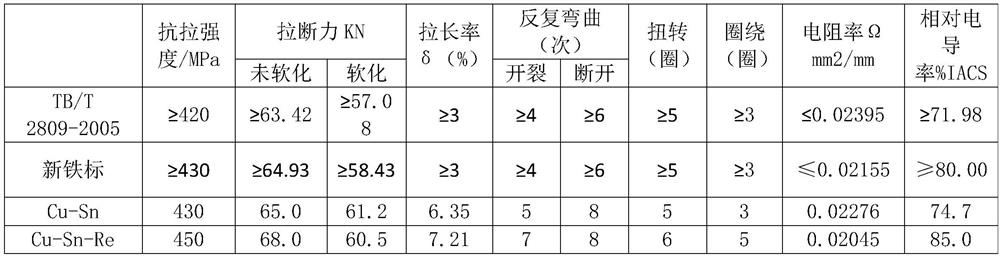

[0019] 1. Alloy composition

[0020] 1.1 Copper-tin alloy composition

[0021] Copper alloy materials are electrolytic copper, tin ingot and rare earth master alloy. Standard cathode copper is used, the composition is: 99.00%; tin ingot (chemical composition: Sn≥90.90%), the rare earth is added as La-Ce mixed rare earth (master alloy); B is added as master alloy. Table 1 is the composition of the copper-tin alloy used in this patent.

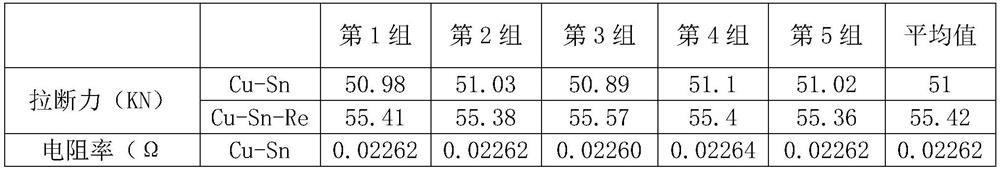

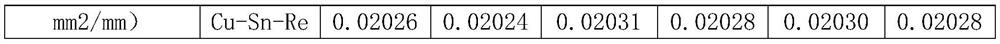

[0022] Table 1 Copper-tin alloy composition

[0023] alloy Re B sn Cu Impurities (less than) Cu-Sn - - 0.3 margin 0.1 Cu-Sn-B 0.05 0.25 margin 0.1 Cu-Sn-Re 0.05 - 0.25 margin 0.1

[0024] 1.2 Ingredients Calculation

[0025] When formulating alloys, Cu and Sn all use ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap