Suspension sliding type welding device and using method

A welding device and a sliding technology, applied in the field of welding processing, can solve the problems of affecting welding quality, easily causing fatigue, and difficult control of manual arc welding, etc., and achieve the effects of saving manpower, reducing operation difficulty, improving welding quality and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

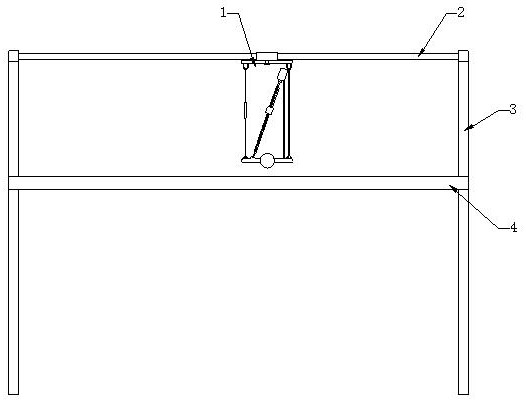

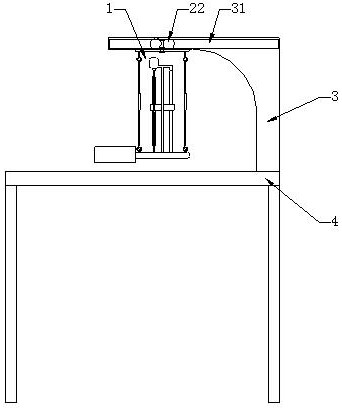

[0032] Such as figure 1 , 2 As shown, a floating sliding welding device includes a floating sliding group 1, a guide rail 2 and two brackets 3; groove 31, the guide rail 2 is installed between the two brackets 3, and two runners 22 slidingly connected with the chute 31 are respectively installed at the two ends of the guide rail 2; the suspension sliding group 1 is movably installed on the guide rail 2; by setting two A runner 22 and a chute 31 can not only ensure that the guide rail 2 is always perpendicular to the bracket 3, but also enable the suspension sliding group 1 to slide along the guide rail 2 and slide along the guide rail 2 along the chute 31, so that the suspension sliding group 1 The front, back, left, and right positions are all adjustable, making welding more flexible.

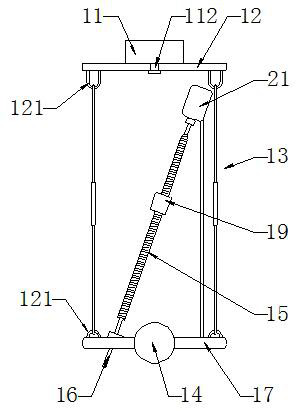

[0033] Such as image 3 , Figure 4 As shown, the suspension sliding group 1 includes a top plate 12, a bottom plate 17, a driving group and an electrode clamp 19 for installing an electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com