Hollow insulator and glass fiber tube depoling device

A technology of insulators and glass fiber tubes, applied in the field of insulator manufacturing, can solve the problems of high labor intensity and high labor costs, and achieve the effect of improving the overall strength, small volume and weight, and large operable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

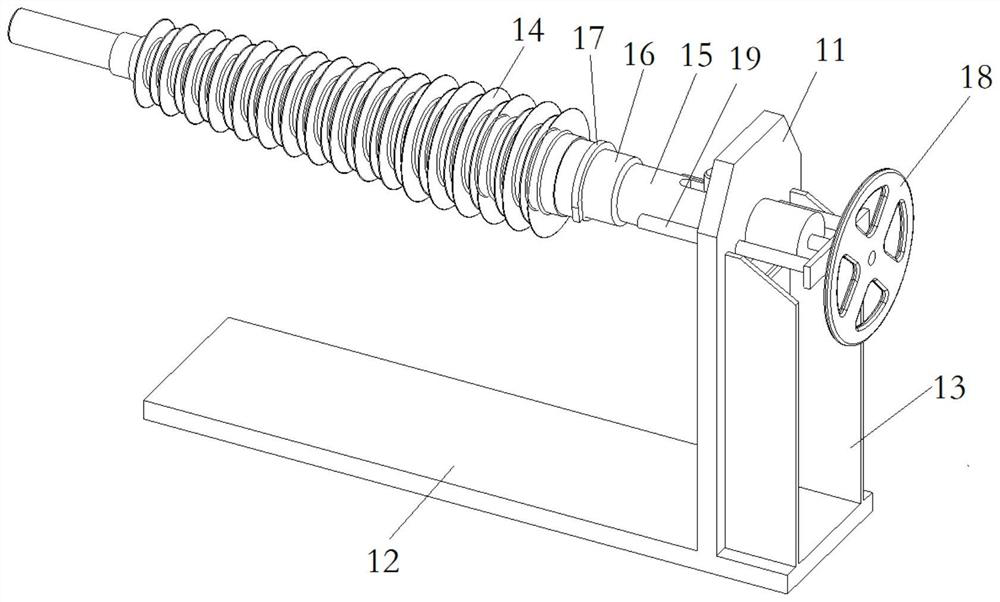

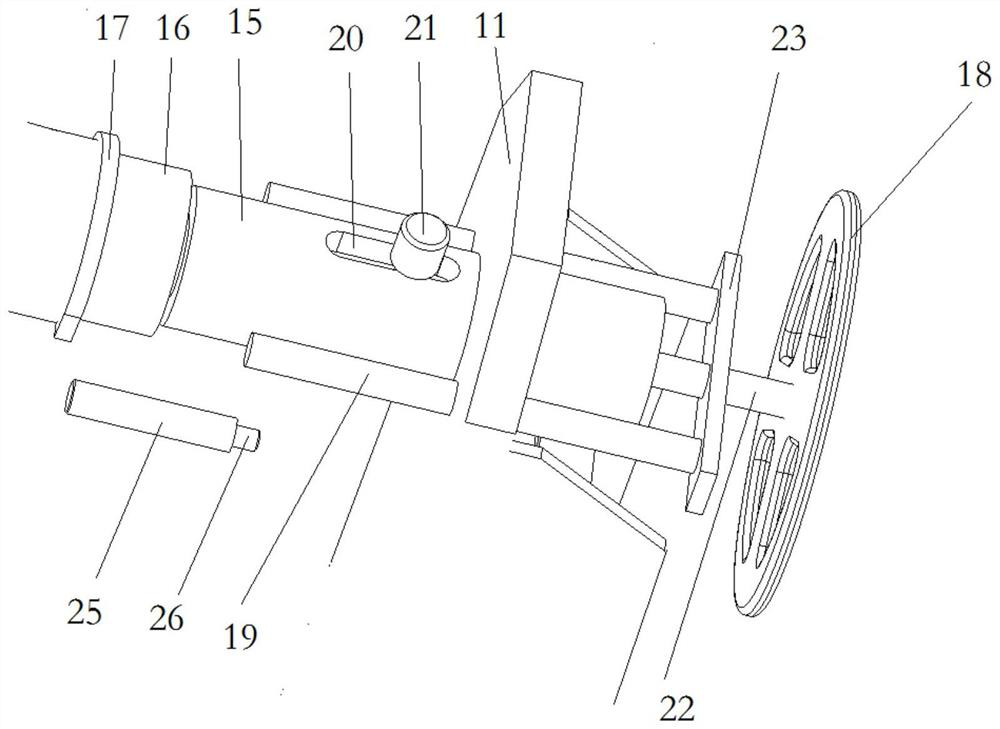

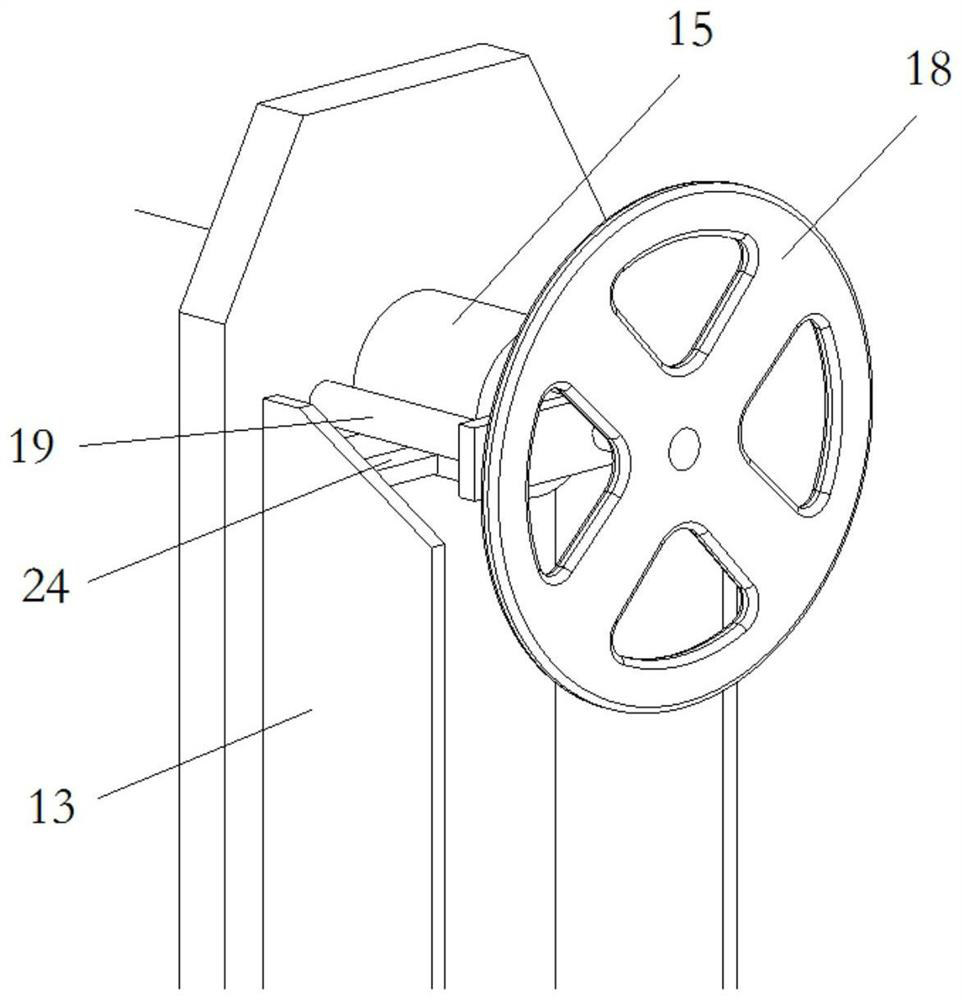

[0038] The hollow insulator and glass fiber tube core stripping device of the present invention is suitable for the demoulding of hollow insulators and glass fiber tubes. In this embodiment, the hollow insulator and the glass fiber tube core stripping device are used to demould the hollow insulator 14 . Such as figure 1 As shown, the hollow insulator and glass fiber tube core removing device includes a support frame and a pushing part for pushing the hollow insulator 14 . The support frame includes a vertical plate 11, and the pushing parts are movably assembled on the vertical plate 11 along the horizontal direction, and the vertical plate 11 is fixed on the bottom plate 12, and the bottom plate 12 is used to extend along the length direction of the hollow insulator 14 to increase the supporting area of the support frame , improve the stability of the support frame. Moreover, two reinforcing plates 13 arranged in parallel and spaced apart are provided at the junction of t...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the support frame includes a bottom plate 12 extending along the length direction of the hollow insulator or fiberglass tube, and a reinforcing plate 13 is arranged between the bottom plate 12 and the vertical plate 11 . In this embodiment, on the premise that the connection strength between the bottom plate 12 and the vertical plate 11 can meet the requirements of use, the reinforcing plate can be omitted. In other embodiments, the supporting frame includes a circular platform at the bottom and a vertical plate fixed on the circular platform.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the supporting blocks 24 are fixed on opposite sides of the two reinforcing plates 13 to support the end of the push rod away from the hollow insulator or the glass fiber tube. In this embodiment, the support block is fixed on the side of the vertical plate away from the hollow insulator or the glass fiber tube. In other embodiments, if the guide length between the ejector rod and the vertical plate is relatively large and the weight of the hand wheel is not enough to cause the ejector rod to deflect as a whole, the support block can also be eliminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com