Process for adding PT film to cover film of flexible circuit board

A flexible circuit board and flexible circuit technology, applied in the field of circuit board processing, can solve the problems of unstable expansion and contraction of cover film materials, slow production operation efficiency, expansion and contraction of cover film, etc., to increase strength, improve efficiency, and cover film accurately. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

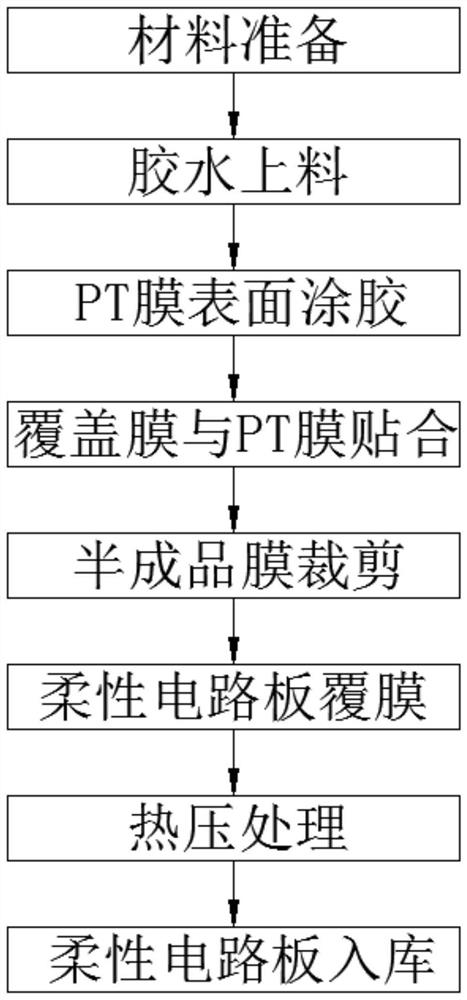

[0040] Example: refer to figure 1 Shown: A process of adding PT film to the cover film of a flexible circuit board. The specific steps of the process of adding PT film to the cover film are as follows S1: Material preparation

[0041] Prepare the required PT film and cover film, and transport the required glue to the gluing equipment, and then install the PT film on the gluing equipment;

[0042] S2: Glue feeding

[0043] Pour the prepared glue into the gluing equipment, and pour the glue into the rubber cylinder of the gluing equipment, and start the heating function of the rubber cylinder at the same time, so that the glue is in a softened state, so as to ensure that the glue can enter the gluing mechanism smoothly internal;

[0044] S3: Glue on the surface of PT film

[0045] Pull out one end of the PT film, and ensure that the PT film passes under the gluing mechanism, and install the PT film through the end of the gluing mechanism on the rewinding mechanism, and the PT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com