Flame-retardant carpet and manufacturing method thereof

A manufacturing method and carpet technology, applied in chemical instruments and methods, synthetic resin layered products, transportation and packaging, etc., to achieve the effect of improving flame retardancy and meeting molding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

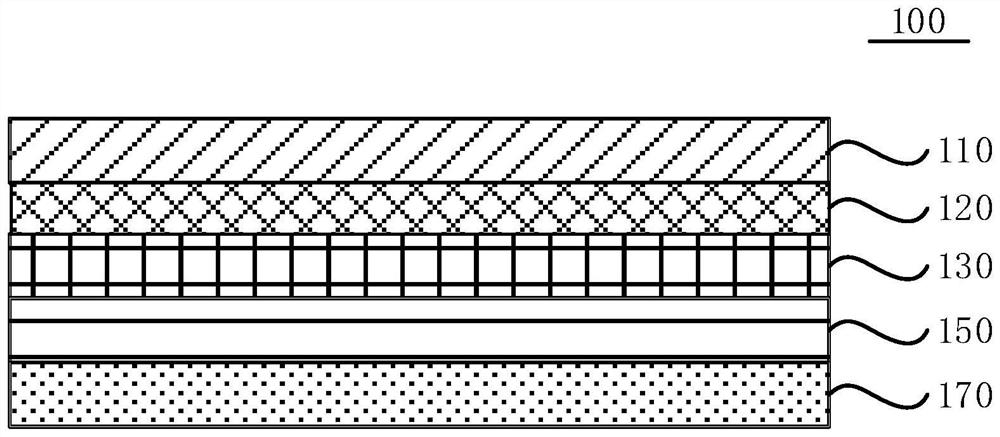

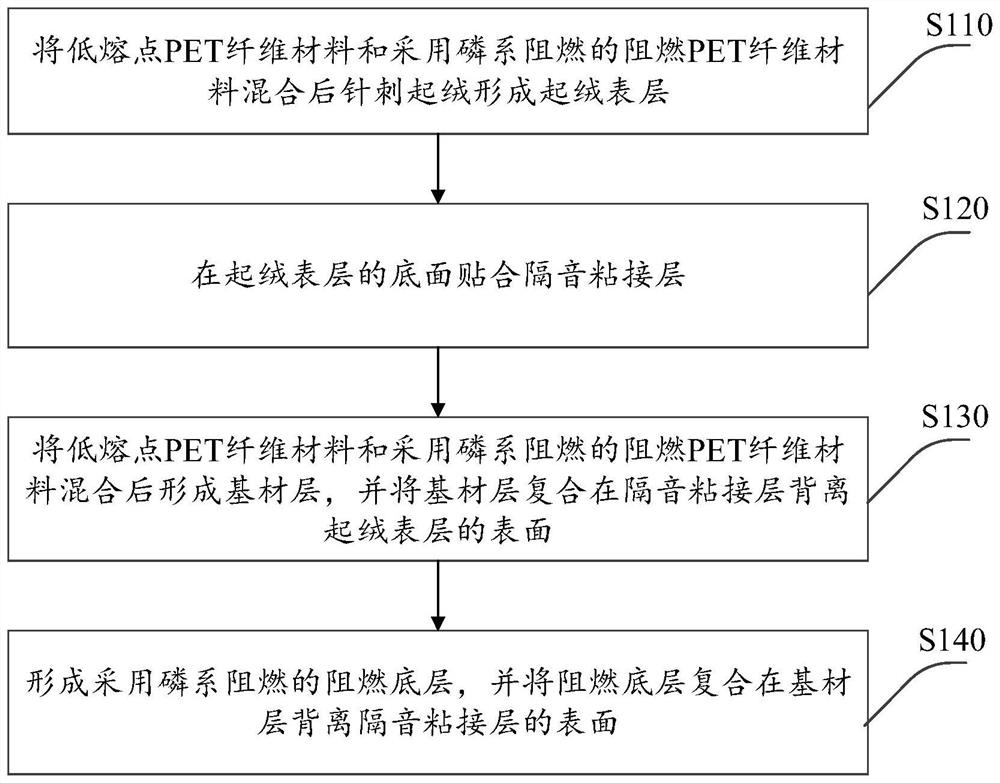

[0082] Embodiment 1 of the present application provides a flame-retardant carpet, which includes a pile surface layer, a flame-retardant latex layer, a sound-insulating adhesive layer, a base material layer, and a flame-retardant bottom layer arranged in sequence.

[0083] The fleece surface layer contains flame-retardant PET fiber material and low-melting fiber PET material, and the weight of the fleece surface layer is equal to 400g / m 2 . Among them, the fiber fineness of the flame-retardant PET fiber material is 8D, and the fiber length is 76mm. The flame-retardant method adopts a phosphorus-based copolymerization flame-retardant method, and the mass percentage of phosphorus element is 0.9%. The fiber fineness of the low melting point PET fiber material is 4D, and the fiber length is 51 mm. The mass proportion of the flame-retardant PET fiber material in the fleece surface layer is 90%, and correspondingly, the mass proportion of the low melting point PET fiber material in...

Embodiment 2

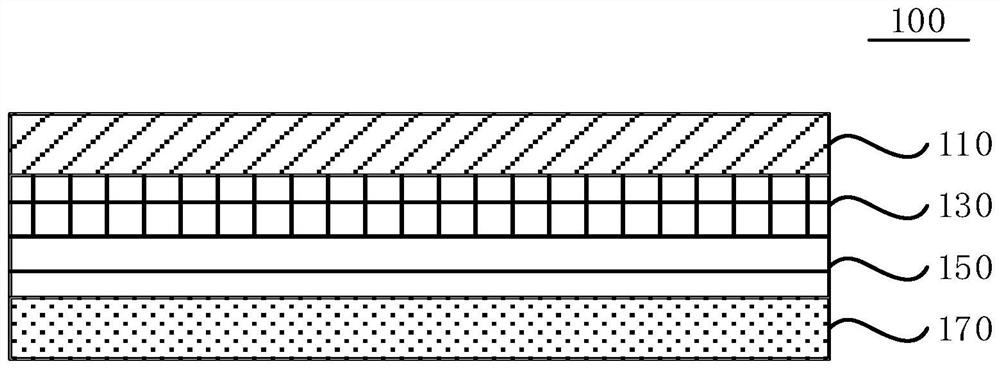

[0095] Embodiment 2 of the present application provides a flame-retardant carpet, which includes a pile surface layer, a sound-insulating adhesive layer, a base material layer and a flame-retardant bottom layer arranged in sequence.

[0096] The fleece surface layer contains flame-retardant PET fiber material and low-melting PET fiber material, and the weight of the fleece surface layer is 400g / m 2 . Among them, the fiber fineness of the flame-retardant PET fiber material is 8D, and the fiber length is 76mm. The flame-retardant method adopts a phosphorus-based copolymerization flame-retardant method, and the mass percentage of phosphorus element is 0.9%. The fiber fineness of the low melting point PET fiber material is 4D, and the fiber length is 51 mm. The weight proportion of the flame-retardant PET fiber material in the fleece surface layer is 90%, and correspondingly, the weight proportion of the low melting point PET fiber material in the fleece surface layer is 10%. Th...

Embodiment 3

[0106] Embodiment 3 of the present application provides a flame-retardant carpet, which includes a pile surface layer, a flame-retardant latex layer, a sound-insulating adhesive layer, a base material layer, and a flame-retardant bottom layer arranged in sequence.

[0107] The fleece surface layer contains flame-retardant PET fiber material and low-melting PET fiber material, and the material weight of the fleece surface layer is 350g / m 2 . Among them, the fiber fineness of the flame-retardant PET fiber material is 6D, and the fiber length is 64mm. The flame-retardant method adopts a phosphorus-based copolymerization flame-retardant method, and the mass percentage of phosphorus in the flame-retardant PET fiber material is 0.9%. The denier of the low melting point PET fiber material is 4D, and the fiber length is 51 mm. The weight proportion of the flame-retardant PET fiber material in the fleece surface layer is 90%, and correspondingly, the weight proportion of the low melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Continue burning | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com