Multidirectional placement bracket for automobile ECU (Electronic Control Unit) controller

A controller and multi-directional technology, applied in the field of racks, can solve problems such as increased processing costs, waste of material processing costs, and difficulty in disassembly, and achieve the effects of reducing vibration transmission, protecting use, and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

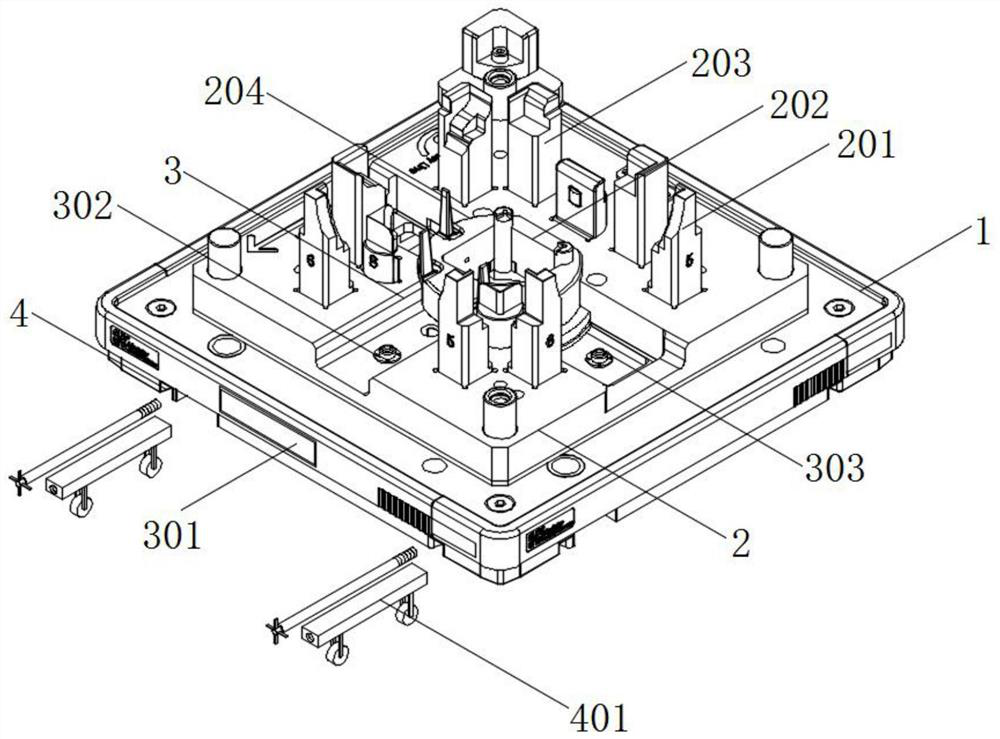

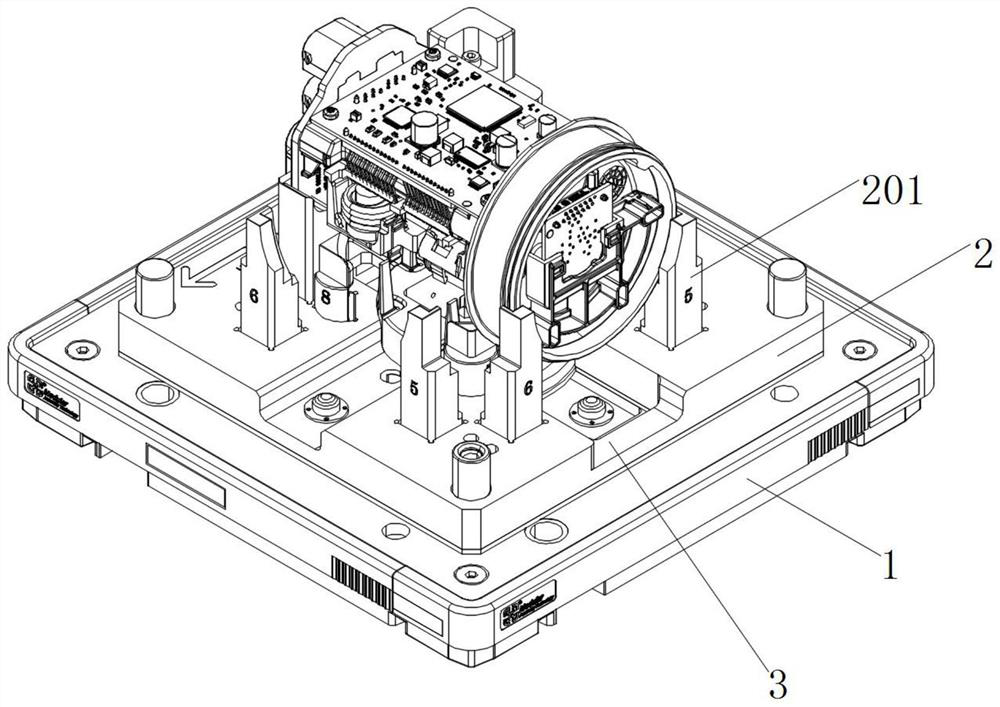

[0040] see figure 1 , image 3 , Figure 4 and Figure 5 , an embodiment provided by the present invention: a multi-directional placement bracket for an automotive ECU controller, including a base 1 and a multi-directional placement bracket 2, and the multi-directional placement bracket 2 is installed on the top of the base 1;

[0041] The top of the multi-directional placement bracket 2 is equipped with a first support base 201 and a third support base 203, and the third support base 203 is arranged with the first support base 201. The top of the multi-directional placement bracket 2 is equipped with two sets of symmetrical The fourth supporting seat 205 is arranged, the bottom wall of the T-shaped groove 3 is equipped with the second supporting seat 202, and the top of the second supporting seat 202 is equipped with three groups of equidistantly arranged plug connectors 204, and each adjacent two groups of plug connectors The angle between the connectors 204 is 60 degrees...

Embodiment 2

[0048] see figure 2 and Figure 6 , an embodiment provided by the present invention: a multi-directional placement bracket for an automotive ECU controller, including a base 1 and a shock absorbing module 5, the bottom of the base 1 is equipped with a shock absorbing module 5, and the shock absorbing module 5 includes The suction cup support 501, the limit block 502, the lifting plate 503, the displacement sensor 504 and the electromagnet 505, the lifting plate 503 is installed on the bottom of the base 1, and the displacement sensor 504 is installed inside the lifting plate 503, The bottom of the lifting plate 503 is fitted with a suction cup support 501, and the four corners of the bottom of the suction cup support 501 are equipped with magnetic suction cups, and the top four corners of the suction cup support 501 are equipped with L-shaped limit blocks 502, and the limit The block 502 and the lifting plate 503 are fitted and connected, and the lifting plate 503 is made of...

Embodiment 3

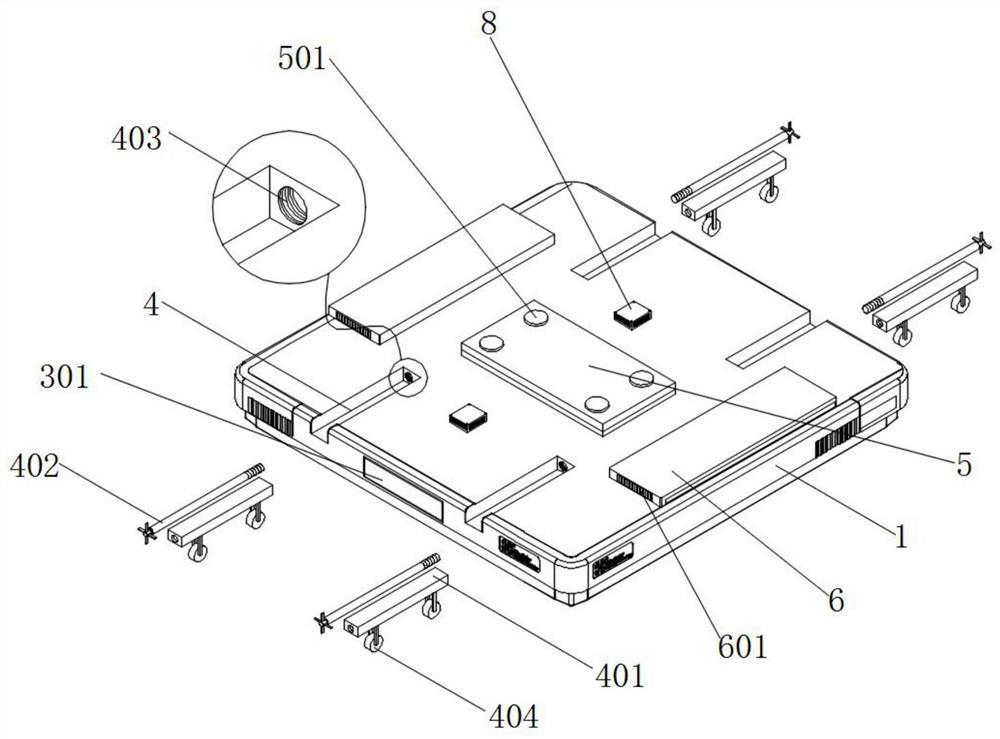

[0053] see figure 1 and figure 2 , an embodiment provided by the present invention: a multi-directional placement bracket for an automotive ECU controller, comprising a base 1 and a moving slot 4, the bottom of the base 1 is provided with an indented moving slot 4, and the moving slot 4 is fitted with a fitting block 401, the bottom of the fitting block 401 is equipped with a moving wheel set 404, the inside of the fitting block 401 is provided with a through hole, and the inner wall of the moving slot 4 is provided with a threaded hole 403, and The threaded hole 403 is on the same axis as the through hole, and a connecting rod 402 is installed through the inside of the through hole, and the length of the connecting rod 402 is greater than that of the fitting block 401. One end is equipped with a turning handle.

[0054] Specifically, insert the fitting block 401 into the inside of the moving slot 4, then insert the connecting rod 402 into the inside of the through hole, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com