Heat sealing mechanism capable of preventing heating wire from being broken and used for packaging machine

A heating wire and packaging machine technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as ductility, damage, lack of heating wire, etc., to avoid defective products and ensure heat sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

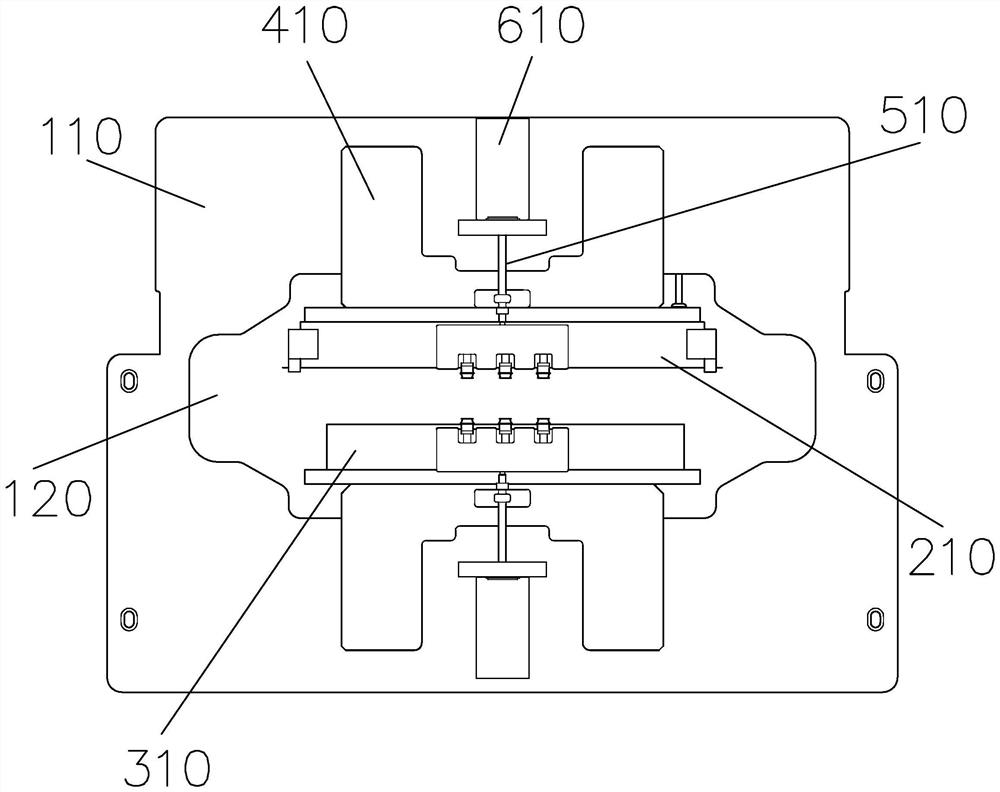

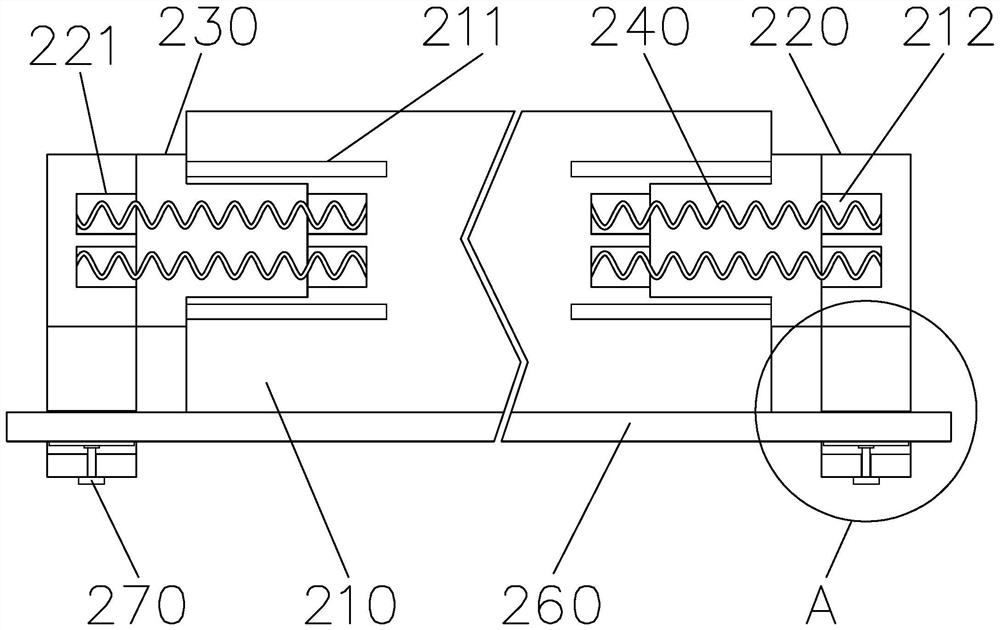

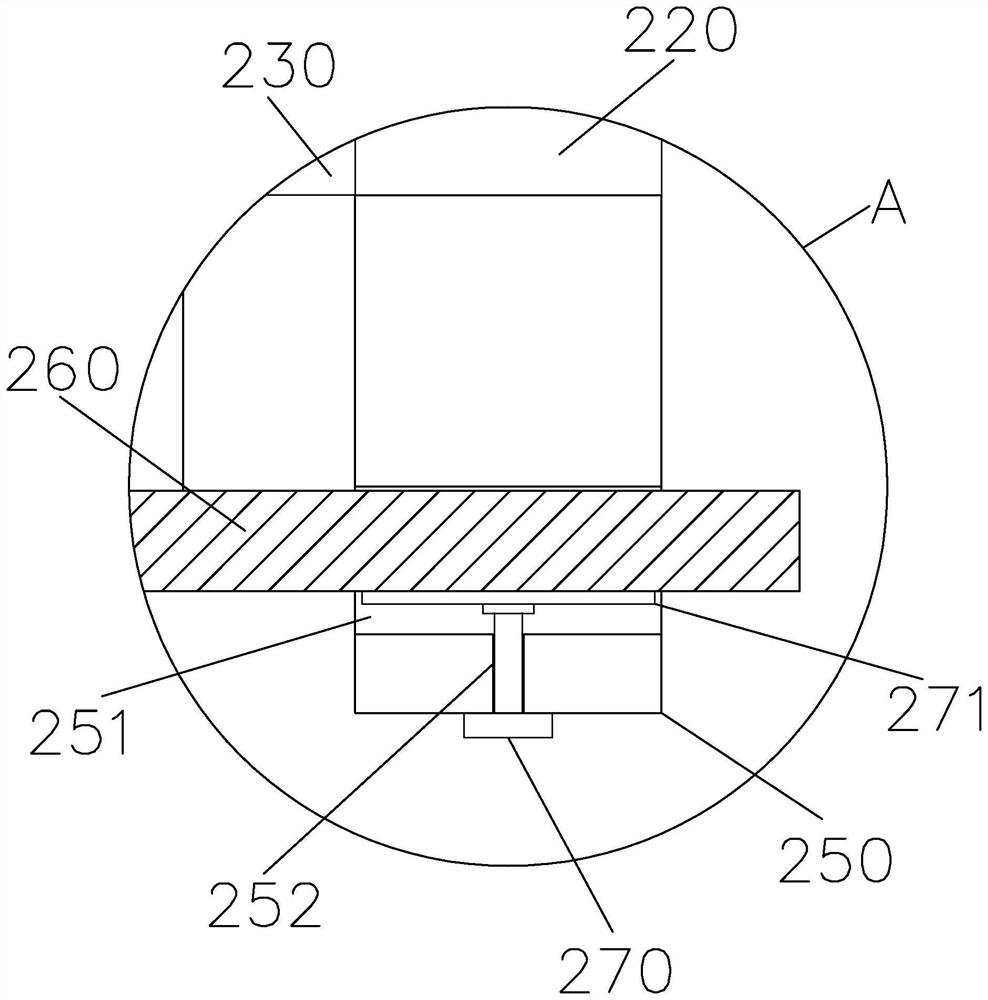

[0028] Embodiment 1: A heat-sealing mechanism for a packaging machine that prevents the heating wire from breaking, including a heat-sealing platform 110, an opening 120 for bagging on the heat-sealing platform 110, an upper heat-sealing copper plate 210 for heat-sealing and The lower heat-sealed copper plate 310, the heating wire body 260 used for heating, the drive mechanism for driving linear movement fixed to the upper heat-sealed copper plate 210 and the lower heat-sealed copper plate 310 respectively, both ends of the heating wire body 260 are fixed by detachable The mechanism is connected with an elastic adjustment mechanism, and the elastic adjustment mechanism is used to realize adaptive movement through the temperature change generated by the heating wire body 260 when it is started and stopped, so as to prevent the heating wire body 260 from breaking, keep the heating wire body 260 tight, and ensure the heat sealing effect .

[0029] Preferably, according to the att...

Embodiment 2

[0035] Embodiment 2: A heat-sealing mechanism for a packaging machine that prevents the heating wire from breaking, including a heat-sealing platform 110, an opening 120 for bagging on the heat-sealing platform 110, an upper heat-sealing copper plate 210 for heat-sealing and The lower heat-sealed copper plate 310, the heating wire body 260 used for heating, the drive mechanism for driving linear movement fixed to the upper heat-sealed copper plate 210 and the lower heat-sealed copper plate 310 respectively, both ends of the heating wire body 260 are fixed by detachable The mechanism is connected with an elastic adjustment mechanism, and the elastic adjustment mechanism is used to realize adaptive movement through the temperature change generated by the heating wire body 260 when it is started and stopped, so as to prevent the heating wire body 260 from breaking, keep the heating wire body 260 tight, and ensure the heat sealing effect .

[0036] Preferably, the elastic adjustme...

Embodiment 3

[0043] Embodiment 3: A heat-sealing mechanism for a packaging machine that prevents the heating wire from breaking, including a heat-sealing platform 110, an opening 120 for bagging on the heat-sealing platform 110, an upper heat-sealing copper plate 210 for heat-sealing and The lower heat-sealed copper plate 310, the heating wire body 260 used for heating, the drive mechanism for driving linear movement fixed to the upper heat-sealed copper plate 210 and the lower heat-sealed copper plate 310 respectively, both ends of the heating wire body 260 are fixed by detachable The mechanism is connected with an elastic adjustment mechanism, and the elastic adjustment mechanism is used to realize adaptive movement through the temperature change generated by the heating wire body 260 when it is started and stopped, so as to prevent the heating wire body 260 from breaking, keep the heating wire body 260 tight, and ensure the heat sealing effect .

[0044] Preferably, the elastic adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com