Feeding device for rod piece machining

The technology of feeding device and rod is applied in the field of feeding device for rod processing, which can solve the problems of trouble and high labor intensity, and achieve the effect of reducing labor intensity, improving applicability, and good stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

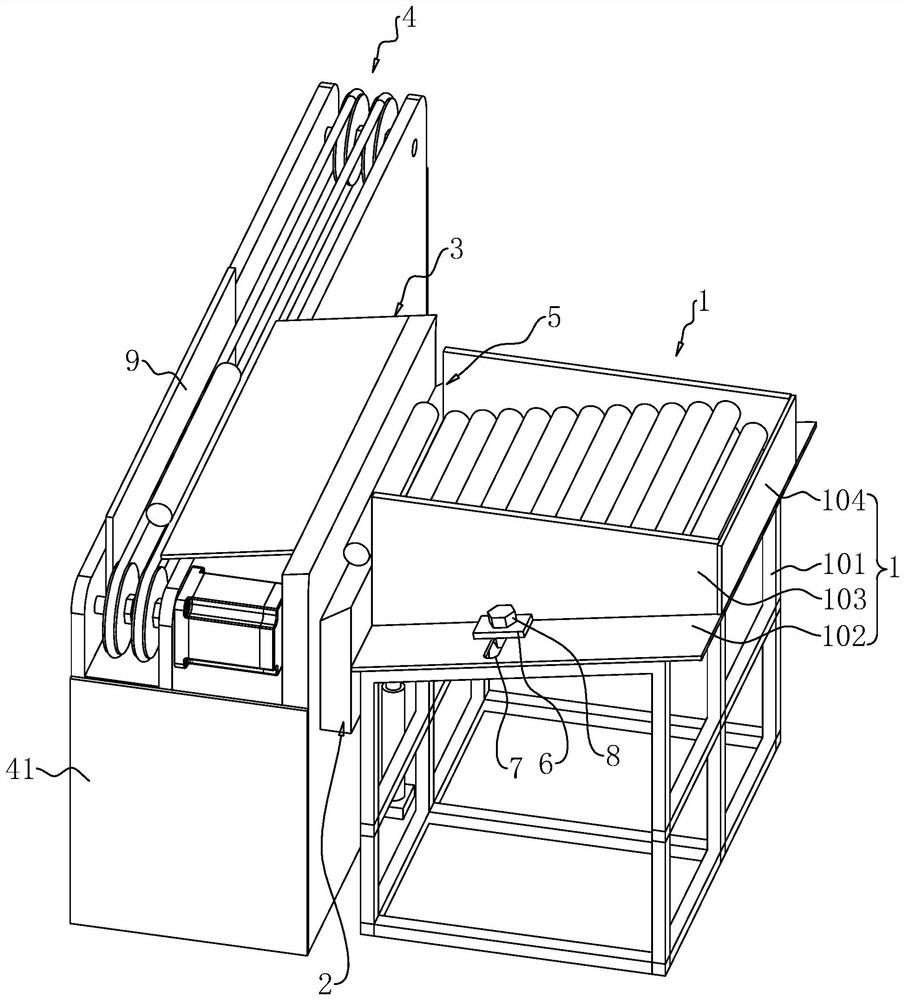

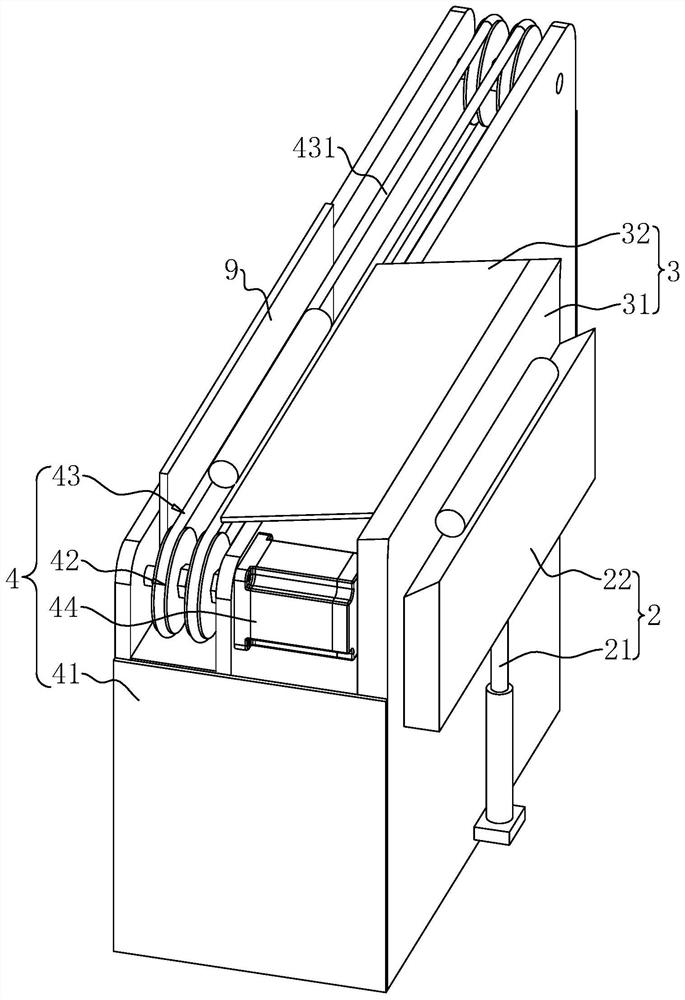

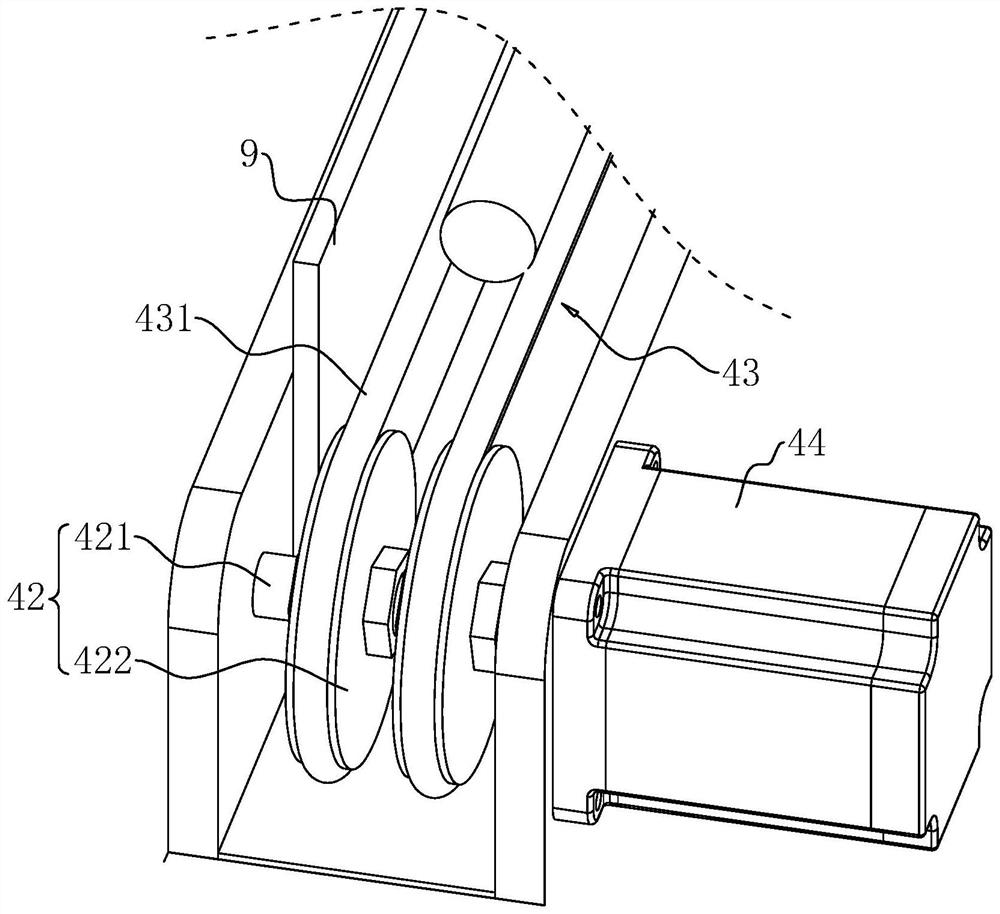

[0034] The following is combined with the attached Figure 1-3 Further elaboration of this application.

[0035] Embodiment of the present application discloses a member processing feed device, mainly suitable for some cross-sectional circular members for feed transportation. Reference Figure 1 The feeding device comprises a storage box 1, a jacking assembly 2, a guide assembly 3 and a conveying component 4 arranged sequentially in a horizontal direction.

[0036] Storage box 1 for centralized storage of multiple members, storage box 1 on the vertical side is provided with a storage box 1 connected to the bottom of the outlet 5, the bottom of the storage box 1 towards the direction of the outlet 5 downward tilt. Specifically, the storage box 1 includes a support foot 101, a base plate 102 that is obliquely fixed to the upper end of the support foot 101, two parallel and spaced side plates 103 fixed to the upper surface of the base plate 102, fixed to the bottom plate 102 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com