Depth-adjustable outer plate punch forming device for computer production

A stamping forming and computer technology, which is applied in the field of external plate stamping and forming devices for computer production, can solve the problems of increased damage rate of the external plate, easy cracking of the external plate surface of the main engine, and strong pressure on the edge of the plate, so as to reduce the number of plates. Loss, easy to automatically collect and clean up waste, save the effect of manpower care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

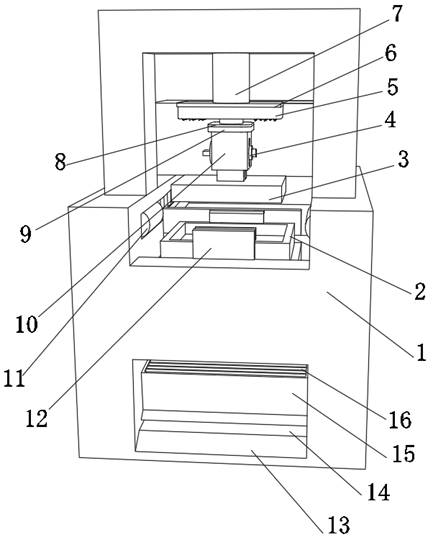

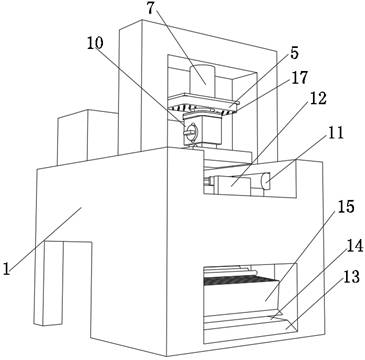

[0034] A depth-adjustable outer plate stamping and forming device for computer production, such as figure 1 , figure 2 and Figure 4-7As shown, including the body 1, the top outer wall of the body 1 is provided with an automatic discharge structure; the inner wall of the opposite side of the body 1 is provided with a combination groove 24, the combination groove 24 is composed of an inclined groove or a horizontal groove, and the inclined groove The inner wall of the bottom of the bottom is connected with a plurality of elastic rubber columns 34 through the rotating shaft, the inner wall of one side of the horizontal groove is fixed with a buffer air bag 11 by bolts, and the inner wall of one side of the buffer air bag 11 is fixed with a plurality of buffers 35 by bolts; the body 1 One side of the inner wall of the body 1 is connected with a mounting plate 26 through a hinge, and the top outer wall of the mounting plate 26 is fixed with a stamping die 2 by bolts; The same b...

Embodiment 2

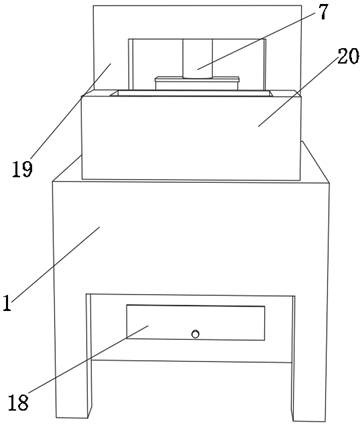

[0040] A depth-adjustable outer panel stamping and forming device for computer production described in Embodiment 1, such as figure 1 , image 3 and Figure 5 , Figure 6 As shown, in order to facilitate the automatic collection and cleaning of waste materials; this embodiment makes the following improvements on the basis of Embodiment 1: one side of the inner wall of the body 1 is fixed with a blanking plate 30 by bolts, one side of the blanking plate 30 and One side of the discharge plate 13 is provided with the same return trough 14, and the return chute 14 has an inclined structure; one side outer wall of the body 1 is connected with a box door 18 through a hinge. During the stamping period and during the period of exporting the stamped sheet, the waste produced by stamping falls through the gap between the rotating roller 28 and the cooling plate 16, and the waste is transported to the machine body 1 from one side of the blanking plate 30 or the return chute 14 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com