Rotary separation device for sludge treatment

A technology of rotary separation and sludge, applied in the fields of sludge treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problems of high water content of sludge, troublesome, poor separation effect of sludge and water, etc. Achieve the effect of improving dewatering quality, reducing parts cost and improving sludge treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

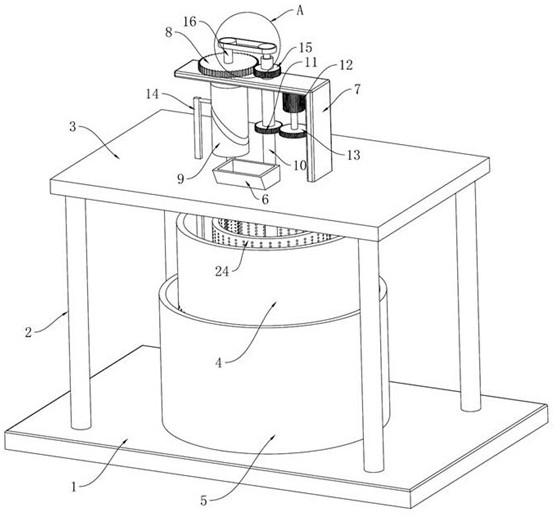

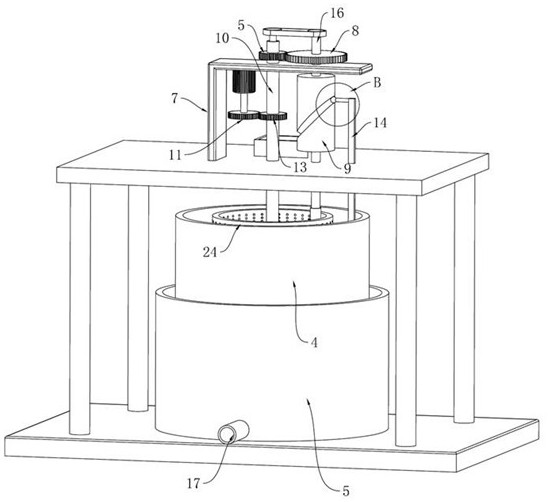

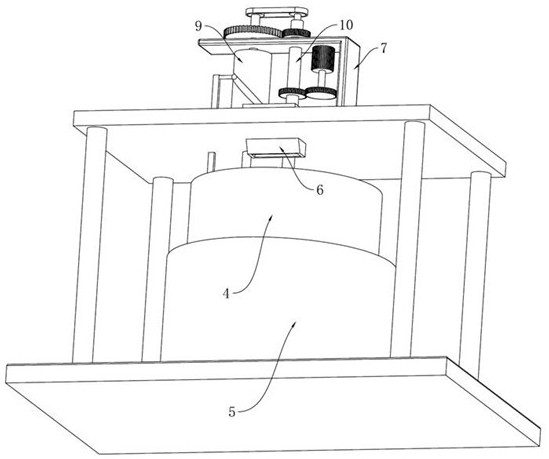

[0035] see Figures 1 to 8 , In the embodiment of the present invention, a rotary separation device for sludge treatment includes a fixed base 1, and the four corners of the upper end of the fixed base 1 are connected with a top plate 3 through a fixed column 2, and a support frame 7 is fixedly installed on the top plate 3. The support frame 7 and the top plate The outer shaft 10 is rotated and connected between 3, the bottom of the outer shaft 10 is installed through the top plate 3 to install the inner centrifugal bucket 24, the top of the outer shaft 10 is connected to the driving gear 15 through the support frame 7, and the outer side of the driving gear 15 is meshed with a driven gear Gear 8, the driven gear 8 is axially fixed to install the rotating shaft 16, the lower end of the rotating shaft 16 is connected to the rotating roller 9 through the support frame 7, the bottom of the rotating shaft 16 is connected to the cleaning roller close to the inner wall of the inner c...

Embodiment 2

[0046] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the support frame 7 is an L-shaped structure, which not only realizes the effective rotation limit of the outer shaft 10 and the rotation shaft 16 , while avoiding the interference between the various components.

[0047] The working principle of the present invention is as follows: during operation, the sludge enters the inner centrifugal bucket 24 through the sewage inlet hopper 6, and then the driving motor 12 is started, and the driving motor 12 will make the inner centrifugal bucket 24 and the outer centrifugal bucket 4 rotate synchronously, The sludge is dewatered twice. After the sewage is stored in the dewatering bucket 5, it is discharged by the drain pipe 17. After the sewage is discharged, the sludge remains in the inner centrifugal bucket 24 and the outer centrifugal bucket 4. , and then open the switch valve, so that the sludge i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com