Multi-combination constant flow pump

A technology of constant flow pumps and pump heads, which is applied to pumps, pump components, components of pumping devices for elastic fluids, etc. It can solve the problem of intermittent work of multiple plunger pumps and the difficulty of realizing continuous pumping of multiple plunger pumps To avoid the interruption of work, improve the sealing performance and achieve the effect of continuous pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

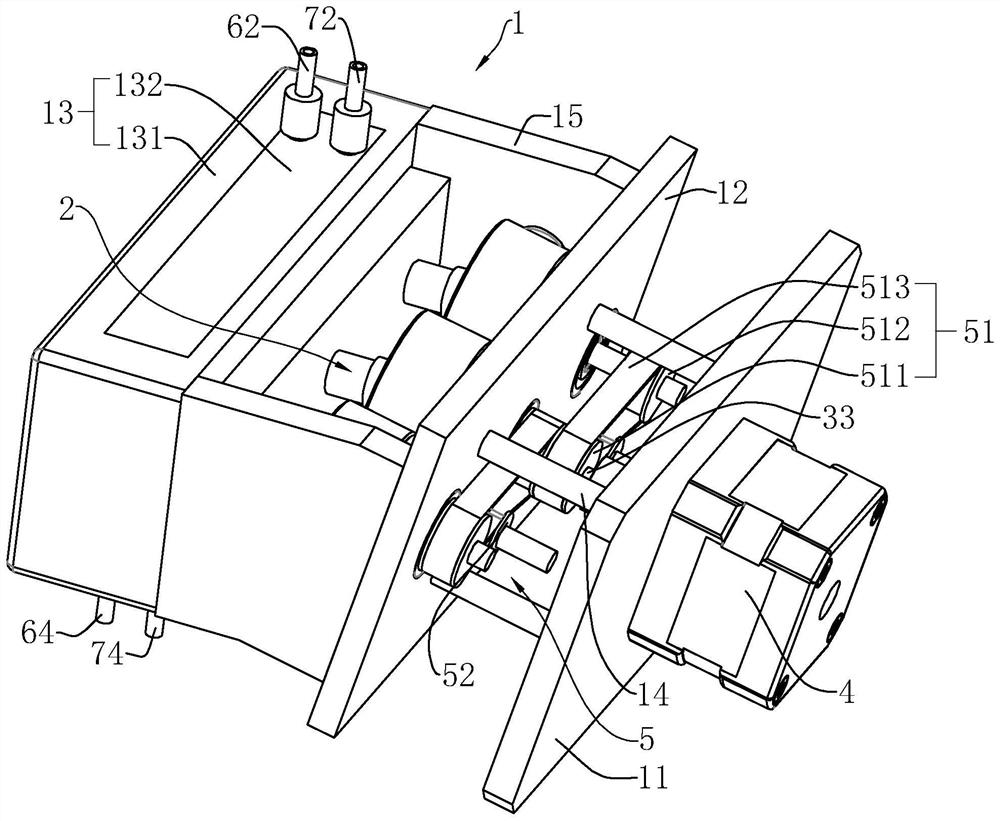

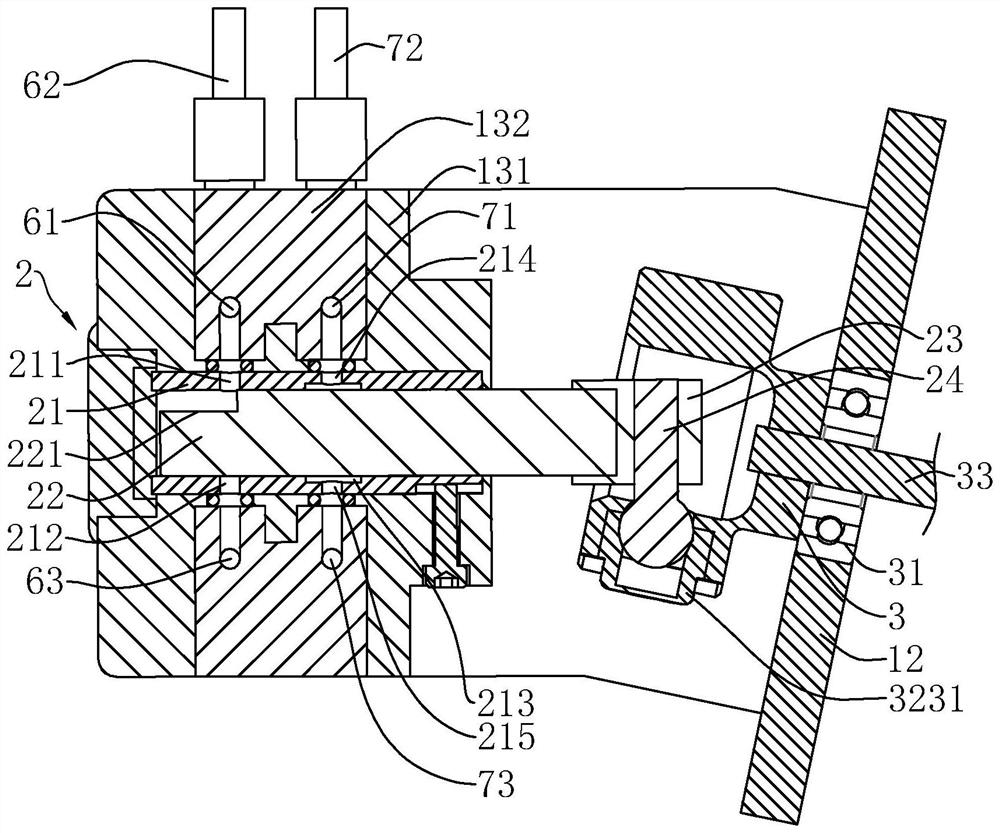

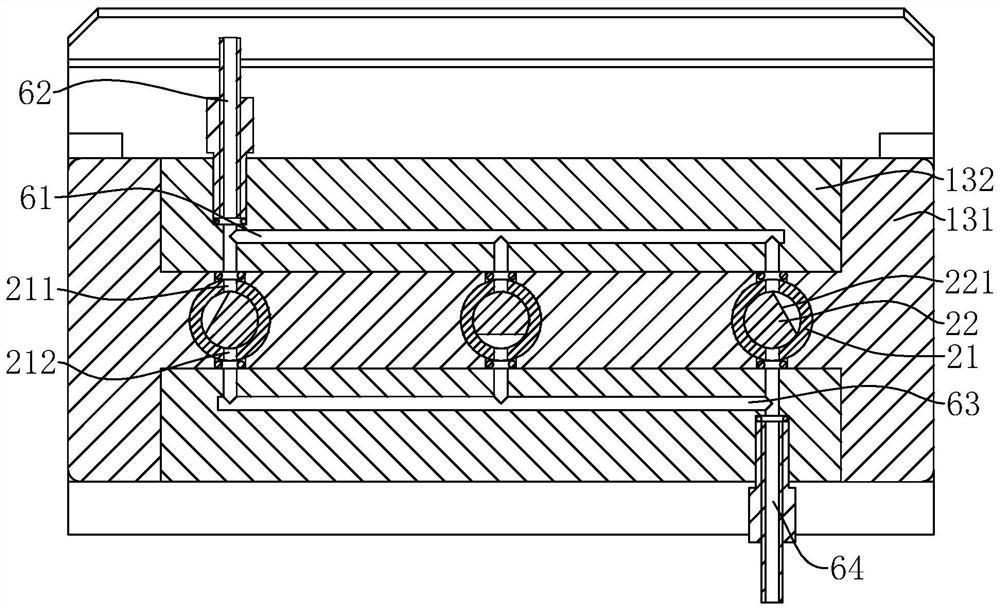

[0044] refer to figure 1 , a multi-combination constant flow pump, including a frame body 1, a pump head 2, a connecting sleeve 3 and a pumping motor 4, a plurality of pump heads 2 are arranged side by side at intervals, and the connecting sleeves 3 correspond to the pump heads 2 one by one. The axes of the pump heads 2 are parallel to each other, and in this embodiment, there are preferably three pump heads 2 . A transmission mechanism 5 for synchronous rotation is arranged between the plurality of connection sleeves 3 , and the pumping motor 4 drives the plurality of connection sleeves 3 to rotate synchronously to control the plurality of pump heads 2 to realize non-intermittent continuous pumping of liquid.

[0045] The frame body 1 includes a motor bracket 11 for installing the pumping motor 4, a connecting sleeve bracket 12 for installing the connecting sleeve 3, a pump head bracket 13 for installing the pump head 2, the motor bracket 11 and the connecting sleeve bracket ar...

Embodiment 2

[0073] combine Figure 5 with Image 6 , a multi-combination constant flow pump. The difference from Embodiment 1 is that the fixed frame 131 includes a single pump frame 1311 corresponding to the pump head 2, and the adjacent single pump frames 1311 are detachably connected. The specific connection mode between two single pump frames 1311 is that two adjacent single pump frames 1311 are respectively provided with socket slots 81 and socket blocks 82 on the two side walls close to each other, and the socket blocks 82 are inserted into the socket slots. 81 and connected by bolt compression.

[0074] The connection sleeve support 12 includes a single sleeve frame 121 corresponding to the connection sleeve 3 one by one, and the adjacent single sleeve frames 121 are detachably connected. The specific connection mode between two adjacent single sleeve frames 121 is that one single sleeve The side wall of the frame 121 is provided with a clamping groove 91, the clamping groove 91 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com