Method for rapidly measuring permeability on well drilling and logging site

A technology for rapid measurement and permeability, applied in permeability/surface area analysis, cleaning methods using gas flow, cleaning methods and utensils, etc., can solve problems that cannot be well applied to outdoor workplaces, and achieve a high degree of automation , simple operation and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

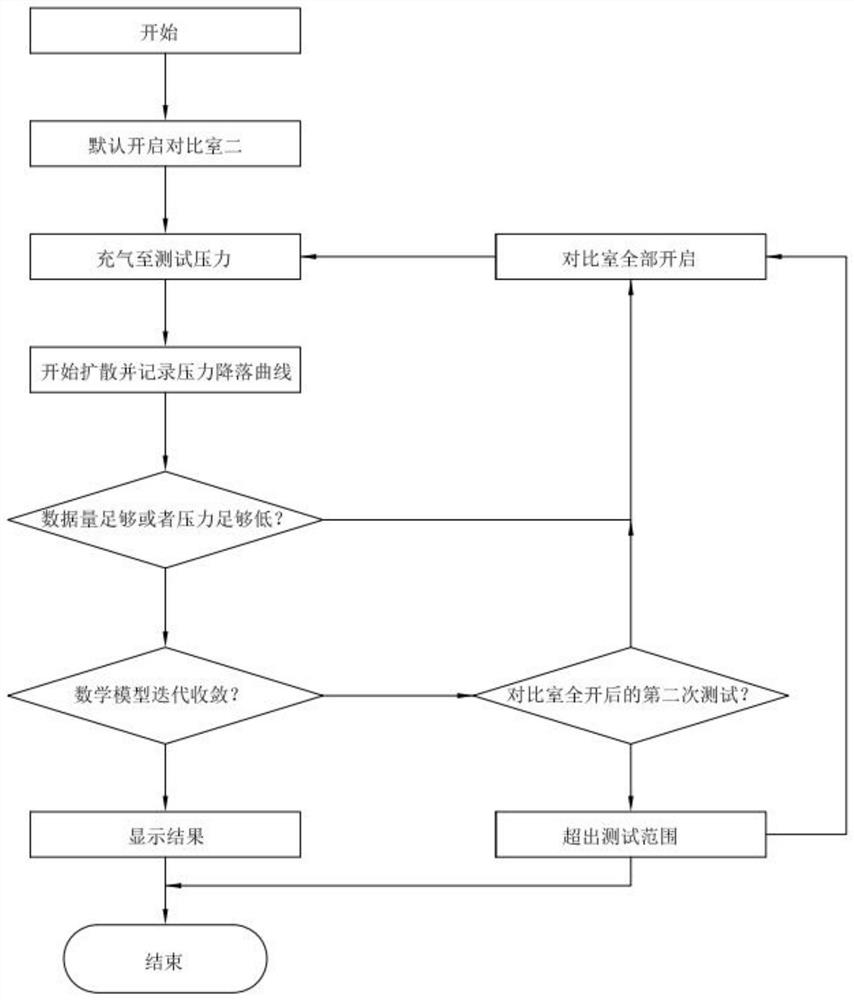

[0047] A method for rapid determination of permeability at the drilling and logging site, the method uses a device for rapid determination of permeability at the drilling logging site, the device includes a superlidge, a box, a control system, a gas supply system, a power supply system, a process system equipment and a simple foldable operating platform, the bottom of the box is provided with a tool sponge groove, each system and components are embedded in the corresponding groove and fixed by snapping or jaw, the operation platform and the top of the side wall of the box are connected by a hinge, and the operating platform can be folded into the box;

[0048] The gas supply system is divided into test gas tanks and cleaning gas tanks, test gas tanks and cleaning gas tanks are equipped with safety vent valves, and equipped with outdoor inflation pumps;

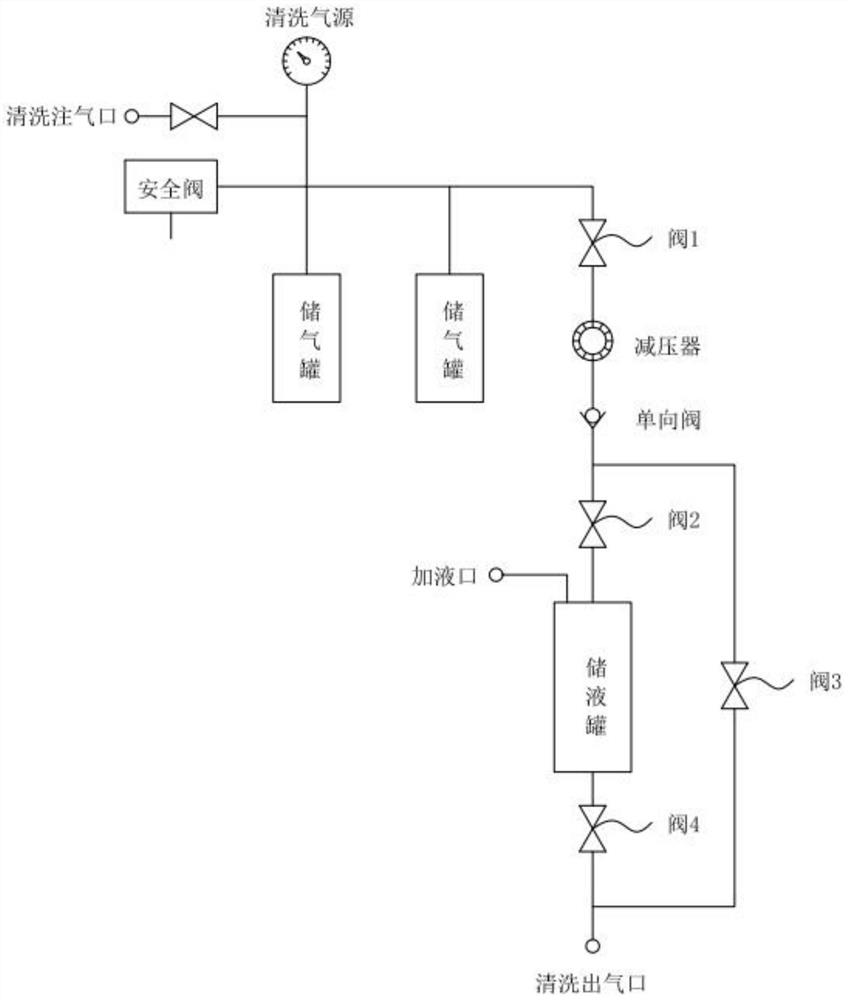

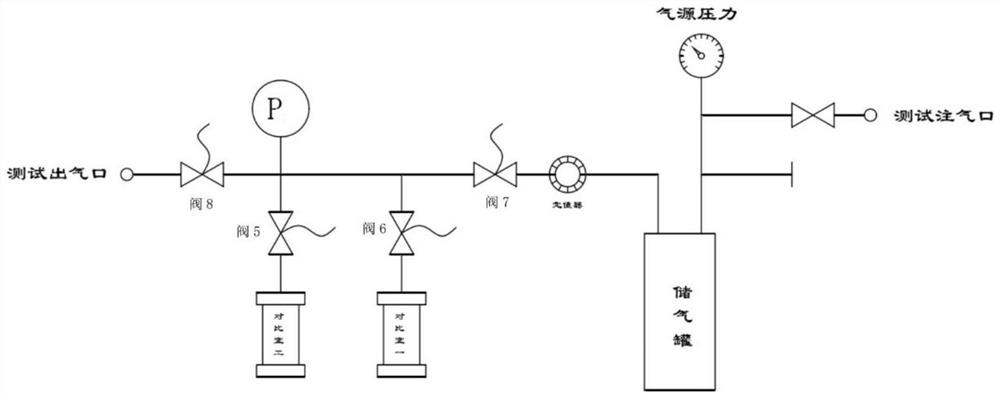

[0049]The process system equipment includes a cleaning system and a test system, the cleaning system includes an organic solven...

Embodiment 2

[0079] The method of rapid cleaning of the sample is similar to Example 1. When the sample is more oily and the cleaning is not clean, the sample can be placed in the core clamping device for testing.

[0080] The core clamping device includes an arc test probe, a pressure plate, a V-shaped positioning block and a fixed support; the arc test probe is located in the uppermost part of the clamping device, the arc surface test probe uses arc-shaped contacts at the top, the upper left side is provided with a lock switch, and the locking switch is provided with an inlet joint; the pressure plate is connected below the arc test probe, and the fixed support is connected below the pressure plate; the middle of the fixed support is provided with a groove that matches the V-type positioning block, the V-shaped positioning block is placed in the groove of the fixed support, and the compression spring is installed below the V-shaped positioning block. Can make the V-shaped positioning block m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com