Defect geometric feature extraction method for infrared nondestructive testing

A technology of infrared non-destructive testing and extraction method, which is applied in material defect testing, analysis of solids using sonic/ultrasonic/infrasonic waves, etc. It can solve the problems of misjudgment of segmentation, difficulty in optimizing thresholds, and cumbersome solution of thresholds. effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

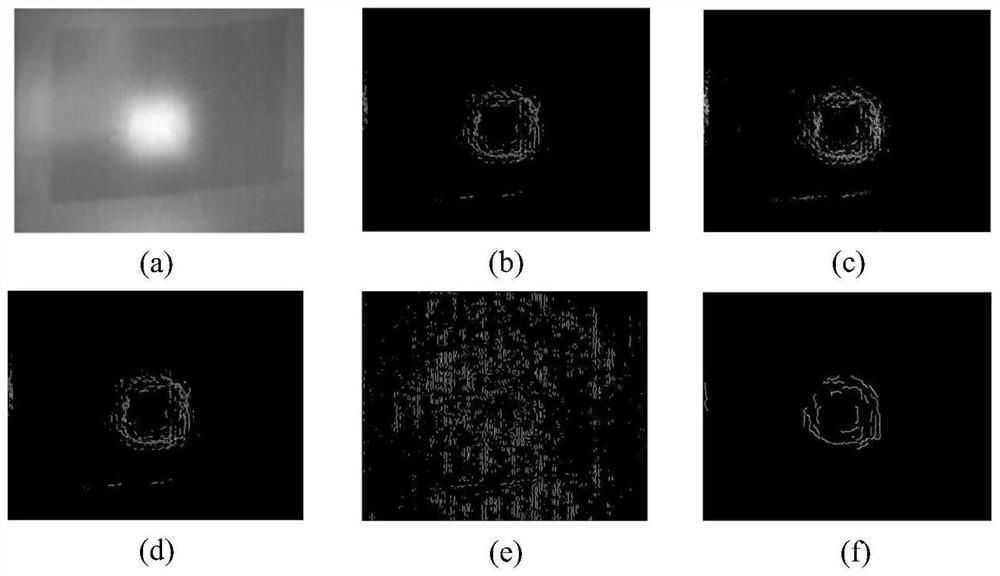

[0098] Using the method of the present invention to image 3 and Figure 4 The infrared original images of the rectangular defect and the triangular defect are processed, and the double thresholds of the infrared image of the rectangular defect are 185 and 204, and the double thresholds of the infrared image of the triangular defect are 115 and 189; and then the morphological edge detection is performed by the step 2 The result is as Figure 6 , Figure 7 As shown, among them, picture (a) is the original detection picture, picture (b) is the result of the maximum entropy double threshold value segmentation based on genetic algorithm, picture (c) is the morphological edge detection based on picture (b) result.

[0099] In order to quantitatively analyze the accuracy of the detection results of the algorithm of the present invention, the geometric characteristics of the rectangular defect are quantitatively analyzed. The geometric size of the actually simulated rectangular de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com