Full-color electronic paper and manufacturing method thereof

A production method and technology of color electronics, applied in the fields of instruments, nonlinear optics, optics, etc., can solve problems such as inapplicable electronic paper preparation methods, polluted pixel areas, high viscosity of liquids, etc., and achieve rich display colors, simple control, and improved The effect of refresh rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for making full-color electronic paper provided by the present invention includes the following steps:

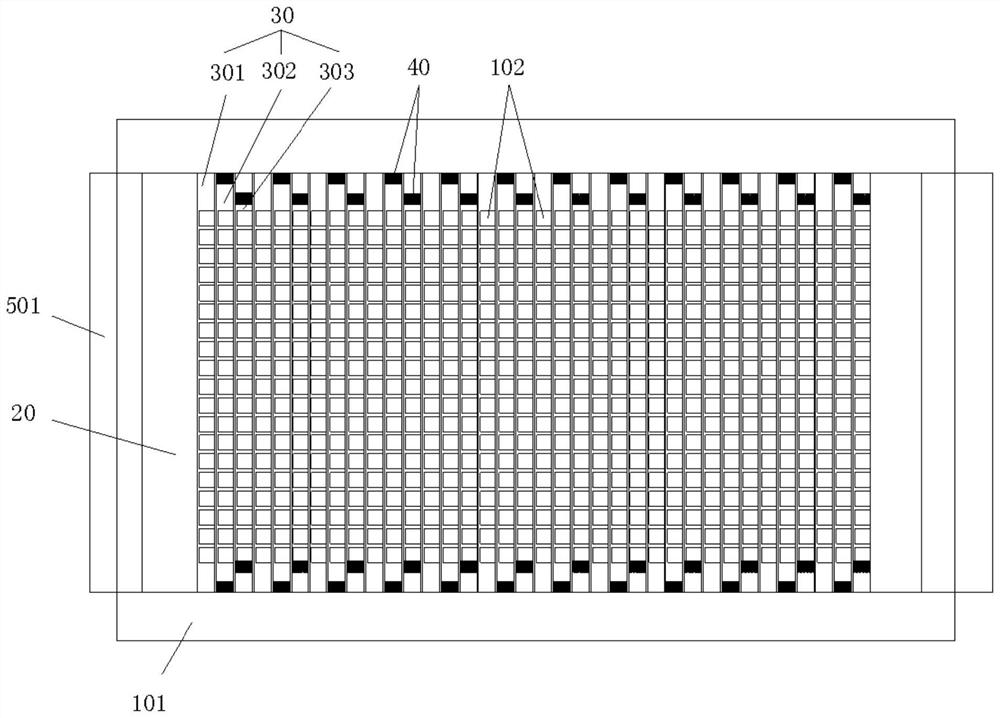

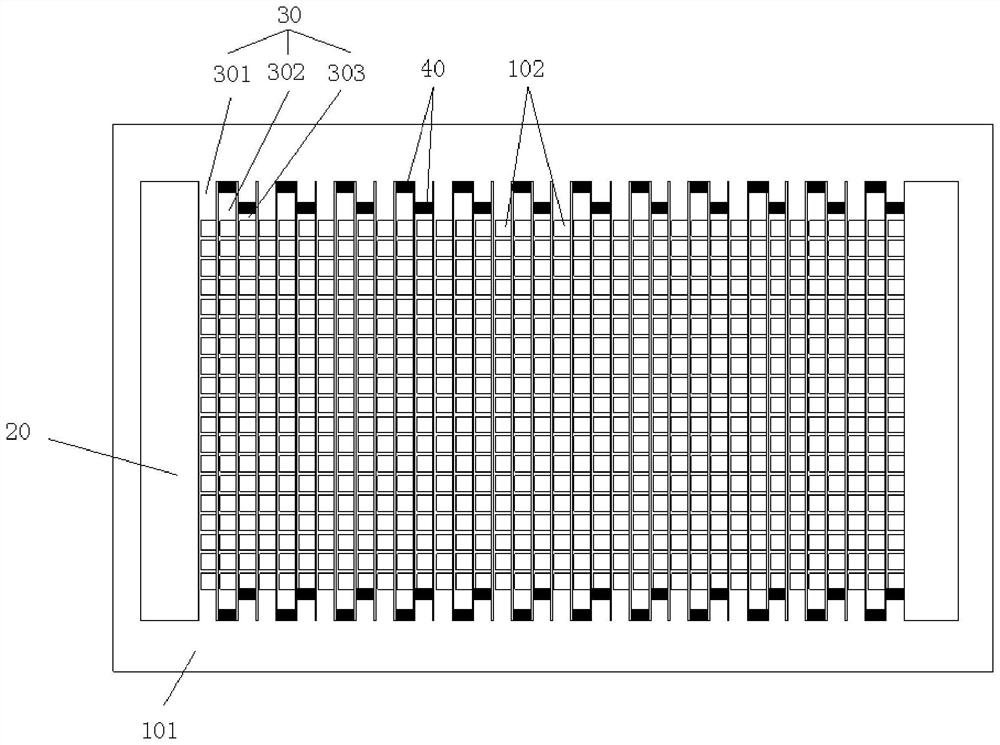

[0033] Such as image 3 As shown, S100: coating a layer of patternable material 20 on the backplane 10, and fabricating at least one pixel unit 30 on the patternable material 20, the pixel unit 30 includes mutually isolated red pixel regions 301 , the green pixel area 302 and the blue pixel area 303, wherein the two ends of any two areas in the red pixel area 301, the green pixel area 302 and the blue pixel area 303 are provided with a barrier layer 40;

[0034] In this embodiment, at least one pixel unit 30 is fabricated on the patternable material 20 by using photolithography and development technology, and the patternable material 20 is a photosensitive resin material.

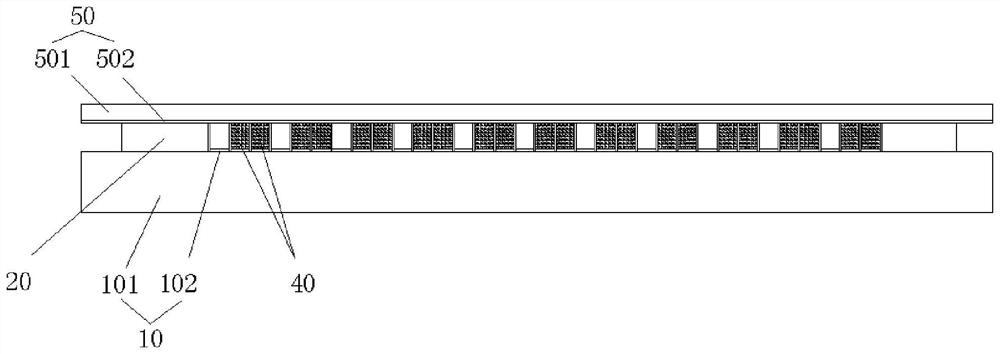

[0035] Such as figure 1 , figure 2 As shown in S200: the cover plate 50 is pasted on the back plate 10, so that the two areas of the red pixel area 301, the green pixel area 302 and t...

Embodiment 2

[0048] This embodiment provides a full-color electronic paper. For the full-color electronic paper prepared according to the above-mentioned embodiments, the preparation process is detailed in the above-mentioned preparation method, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com