Laser output power control device and control method thereof

An output power and control device technology, applied in the laser output power control device and its control field, can solve the problems of the laser being unable to realize continuous adjustment and precise control of the laser output power, etc., and achieve the realization of rotation angle, noise reduction, and good control performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A specific embodiment of the present invention discloses a laser output power control device, which is used for power output regulation and precise control of a fixed power output laser.

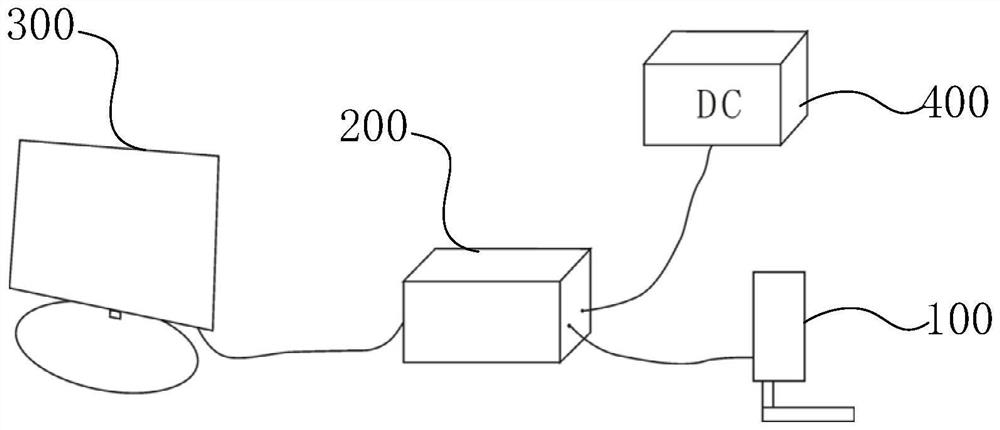

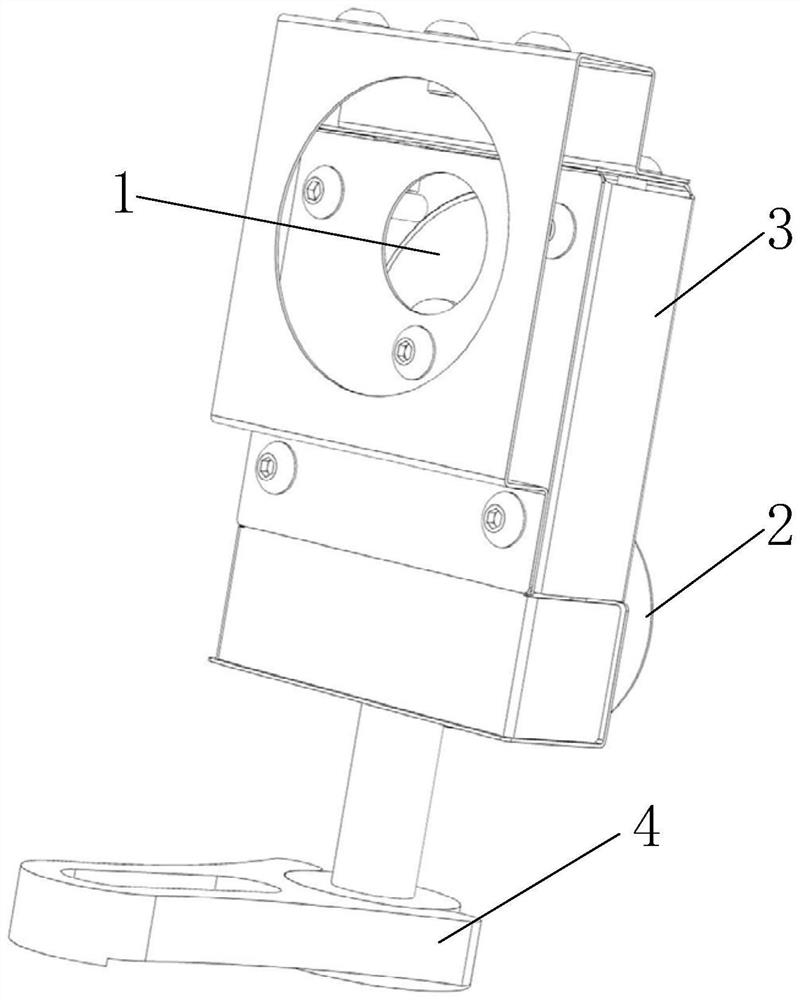

[0077] like Figure 1 to Figure 5 As shown, the laser output power control device includes:

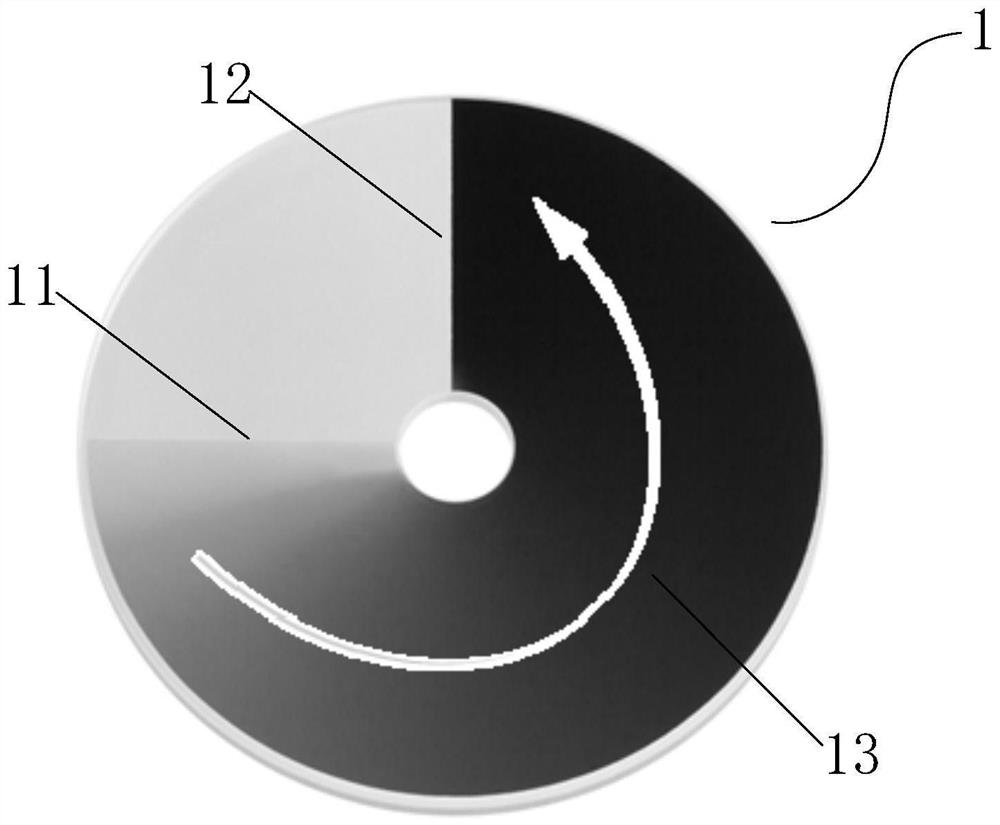

[0078] The attenuator 100, the attenuator 100 includes a neutral attenuator 1 and a drive mechanism 2 for driving the neutral attenuator 1 to rotate; the surface of the neutral attenuator 1 has a coated attenuation area 13, and the attenuation area 13 has a first attenuation boundary 11 and the second attenuation boundary 12, the coating thickness from the first attenuation boundary 11 to the second attenuation boundary 12 increases linearly;

[0079] The controller 200, the controller 200 is electrically connected with the attenuator 100, and controls the rotation of the driving mechanism 2 based on a predetermined program to control the rotation angle of the attenuation area 13, so as to r...

Embodiment 2

[0095] Another specific embodiment of the present invention discloses a control method of a laser output power control device, that is, by controlling the laser output power control device of Embodiment 1, precise control of the laser output power is realized.

[0096] Figure 8 It is a flow chart of the control method of the laser output power control device of an embodiment, such as Figure 8 As shown, the control method of the laser output power control device in one embodiment includes step S100 to step S102:

[0097] S100, acquiring a calibration test result; wherein, the calibration test result includes a mapping relationship between a rotation angle and an output power;

[0098] S101, writing a predetermined program according to the calibration test result;

[0099] S102, sending the predetermined program to the controller 200, so as to instruct the controller 200 to control the rotation of the driving mechanism according to the predetermined program.

[0100] As in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com